Have you ever wondered how people make multiple copies of a document without using a printer or scanner? Carbonless copy paper, also known as NCR paper, does exactly that—and without the mess of old carbon sheets.

Invented in the 1950s by the National Cash Register company, carbonless paper changed how businesses create instant copies. It's clean, easy to use, and found in everything from receipts to contracts.

In this post, you’ll learn how carbonless copy paper works, why it’s so useful, what it's made of, and how it helps businesses run smoothly.

What is Carbonless Copy Paper?

Carbonless copy paper is a specially coated type of paper that creates instant duplicates of handwritten or printed documents without requiring carbon sheets. It allows businesses to efficiently produce multiple copies of invoices, receipts, and forms with a single writing action. When pressure is applied to the top sheet, it triggers a chemical reaction that transfers the markings to the sheets below, creating clear and precise duplicates.

This paper technology is known by several names:

| Common Terms | Description |

| NCR Paper | No Carbon Required paper, named after its inventor, National Cash Register |

| Carbonless Paper | Highlighting its carbon-free duplication capability |

| No Carbon Paper | Emphasizing the absence of traditional carbon sheets |

How is Carbonless Paper Different from Carbon Paper?

| Feature | Carbonless Copy Paper | Traditional Carbon Paper |

| Mess-Free | ✅ Clean & smudge-free | ❌ Leaves ink residue |

| Security | ✅ No retained markings | ❌ Retains impression |

| Copy Quality | ✅ Consistent, clear | ❌ Can blur or smear |

| Eco-Friendliness | ✅ Biodegradable | ❌ Less sustainable |

Unlike carbon paper, carbonless paper doesn’t leave behind smudges or dark ink marks. It’s much cleaner and safer to use, especially in professional environments. They’re also more secure, since carbon sheets could retain the original image, posing privacy risks.

How Does Carbonless Copy Paper Work?

Carbonless copy paper employs an ingenious chemical process to create multiple copies simultaneously without the need for carbon sheets. It relies on pressure-sensitive coatings that transfer markings from the top sheet to underlying sheets through a controlled chemical reaction.

The Chemical Coating Technology Explained

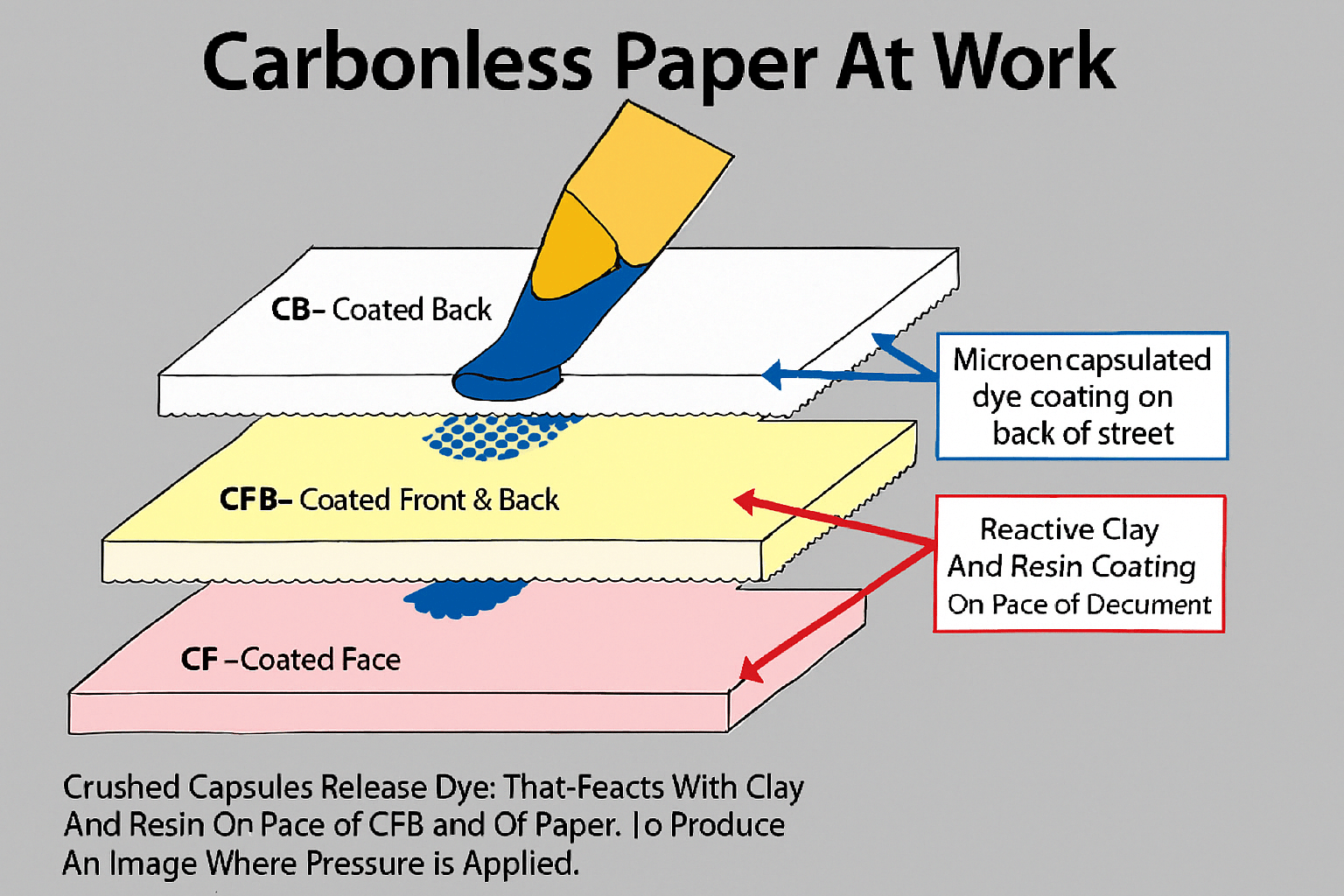

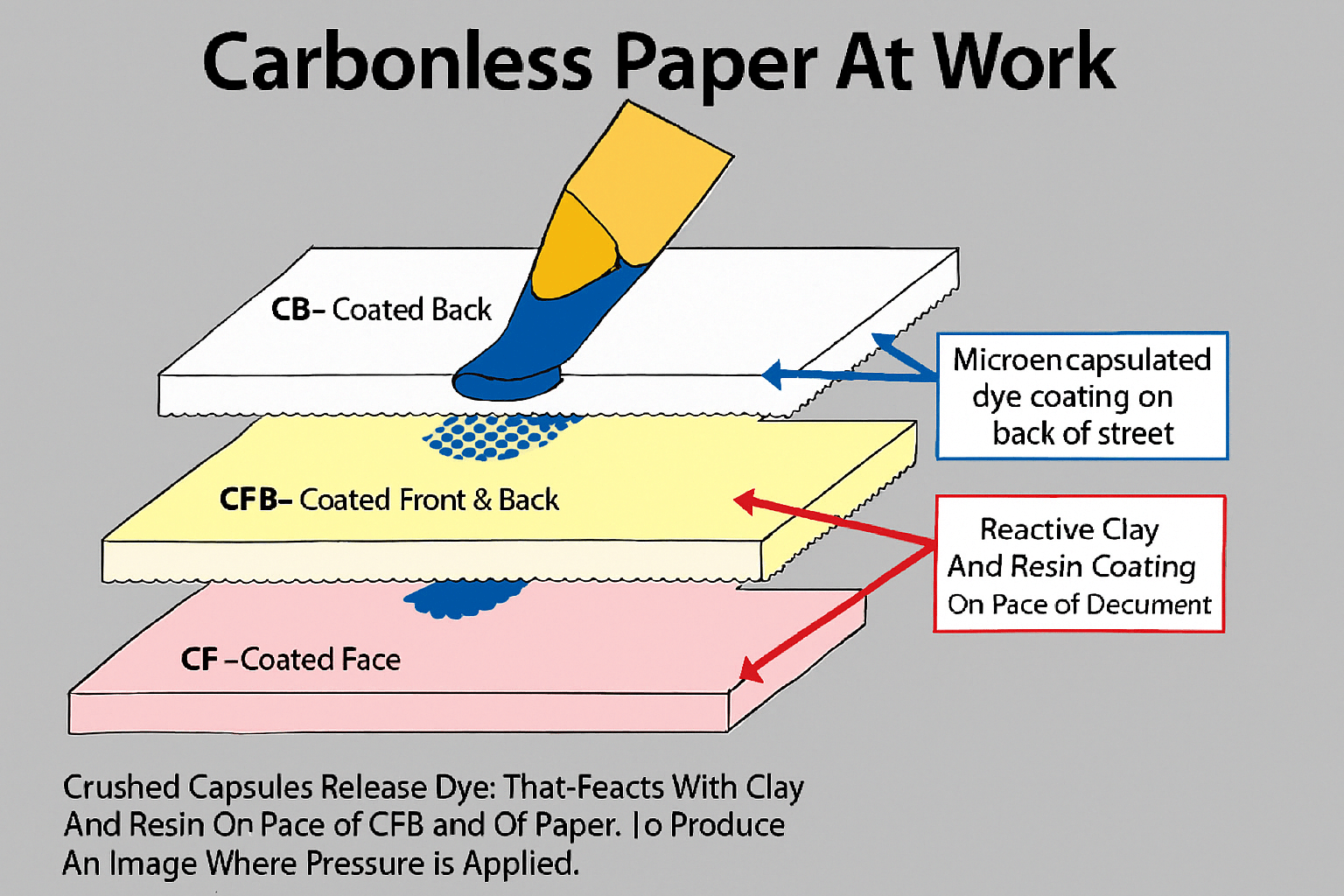

The functionality of carbonless paper depends on a sophisticated microencapsulation technology:

Microencapsulated dye - The back of the top sheet contains microscopic capsules filled with colorless dye formulations

Reactive clay coating - The front of the receiving sheet features a special clay that reacts with the dye

Chemical reaction - When these two components interact, they produce a visible image that replicates the original markings

This technology ensures precise image transfer while eliminating the messiness associated with traditional carbon paper. The microcapsules are designed to rupture under specific pressure thresholds, allowing them to withstand normal handling while still activating during writing or printing.

What Are CB, CF, and CFB Layers?

Carbonless paper utilizes different coating configurations depending on its position in the form:

| Layer Type | Description | Position | Function |

| CB (Coated Back) | Microencapsulated dye on reverse side | Top sheet | Contains pressure-sensitive dye capsules |

| CF (Coated Front) | Reactive clay coating on front side | Bottom sheet | Receives and develops the dye |

| CFB (Coated Front & Back) | Coated on both sides | Middle sheets | Receives dye from above and transfers to sheet below |

For example, a 2-part form uses CB-CF configuration, a 3-part form uses CB-CFB-CF, and a 4-part form uses CB-CFB-CFB-CF arrangement. This systematic layering ensures that writing transfers seamlessly through all copies.

How Pressure Activates the Copy Process

The duplication process begins when pressure is applied to the top sheet:

When we write with a ballpoint pen or use an impact printer, pressure forces the microcapsules on the CB layer to burst

The released dye flows into contact with the reactive clay coating on the CF layer below

They undergo an instant chemical reaction, producing a colored mark that duplicates the original writing

In forms with multiple parts, this process continues through each layer as the pressure transfers downward

This reaction only occurs at points where pressure is applied, creating precise duplicates without affecting surrounding areas. The entire process happens instantaneously, allowing businesses to create professional multi-part forms for invoices, receipts, and legal documents.

Types of Carbonless Copy Paper

Carbonless copy paper has evolved into several specialized formats to accommodate diverse business requirements. Each type offers specific advantages for different applications, ensuring optimal performance across various documentation needs.

2-Part, 3-Part, and Multi-Part NCR Forms

NCR forms consist of multiple sheets designed to create instant duplicates with a single writing action. They utilize standardized color sequences to facilitate quick identification of each copy:

| Form Type | Layers | Common Colors | Typical Use Cases |

| 2-Part Form | CB + CF | White + Yellow | Invoices, delivery receipts |

| 3-Part Form | CB + CFB + CF | White + Yellow + Pink | Work orders, contracts |

| 4-Part Form | CB + CFB + CFB + CF | White + Yellow + Pink + Goldenrod | Medical records, multi-department forms |

These color combinations help businesses instantly recognize the purpose of each copy—typically, white for customers, yellow for accounting, pink for shipping, and goldenrod for internal records. The consistent coloring system allows organizations to distribute copies efficiently to the appropriate departments.

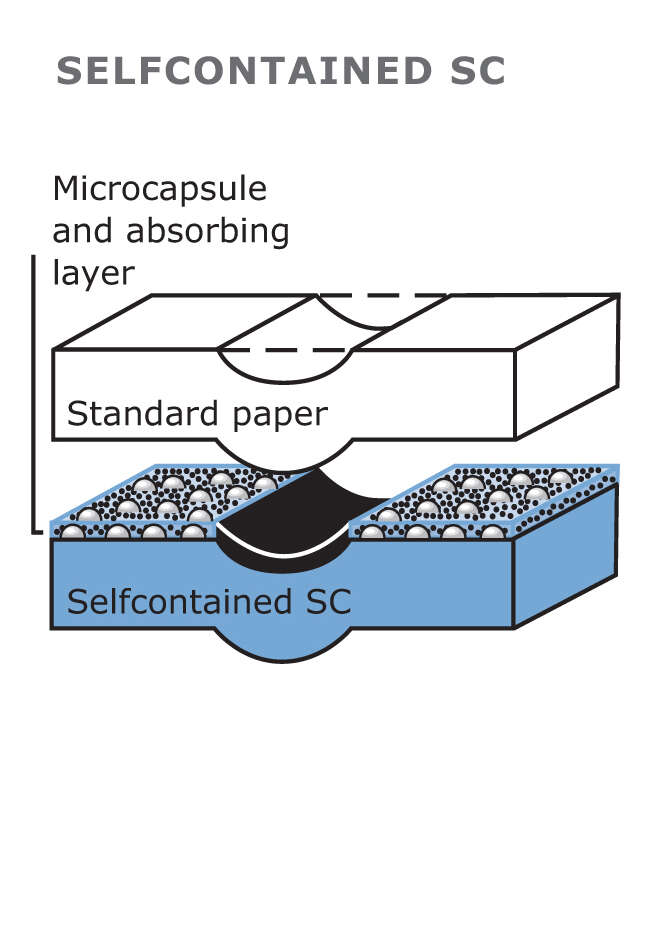

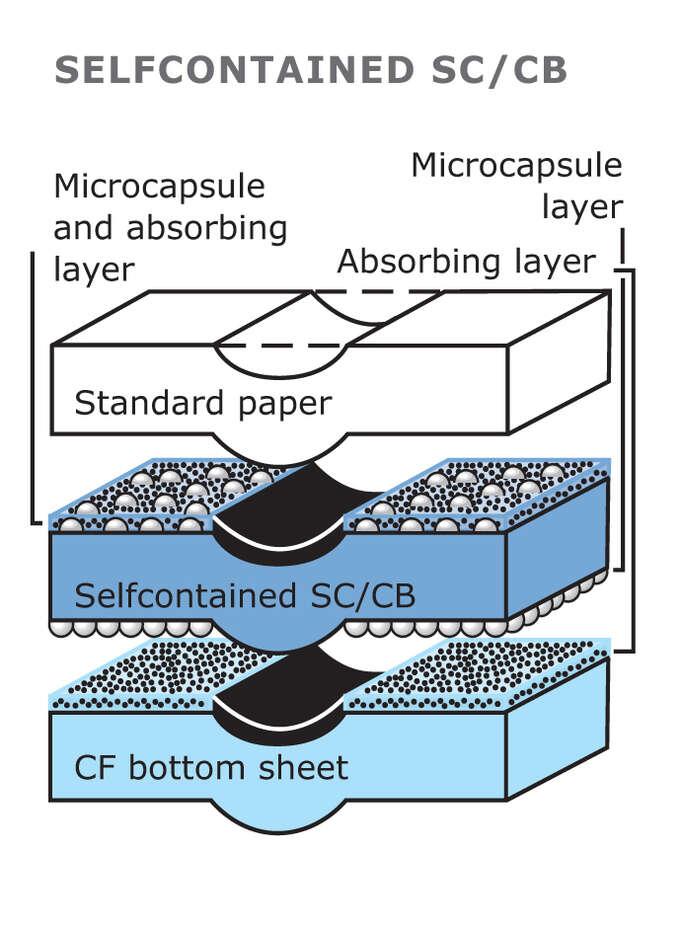

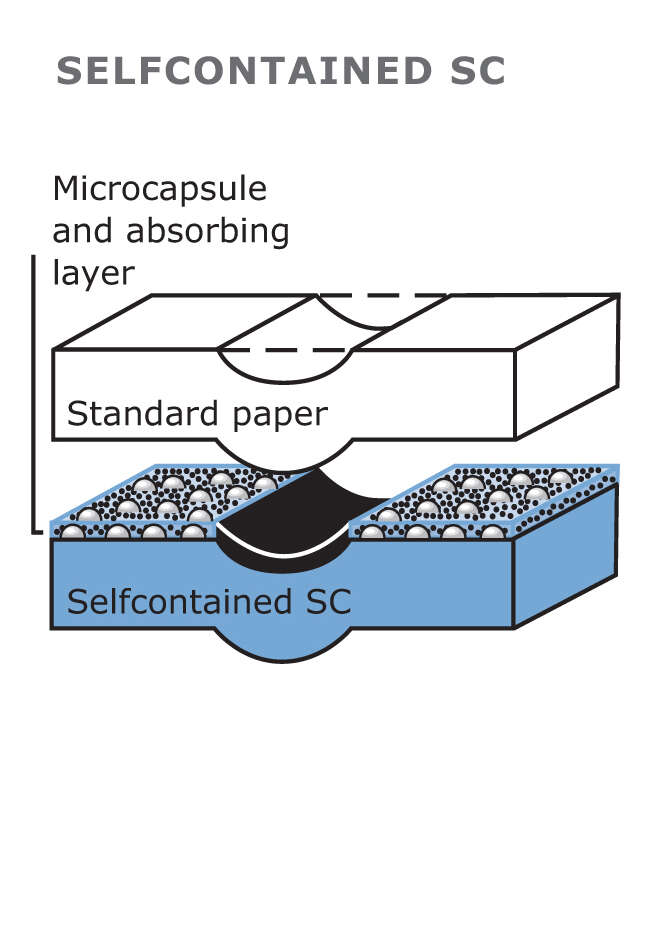

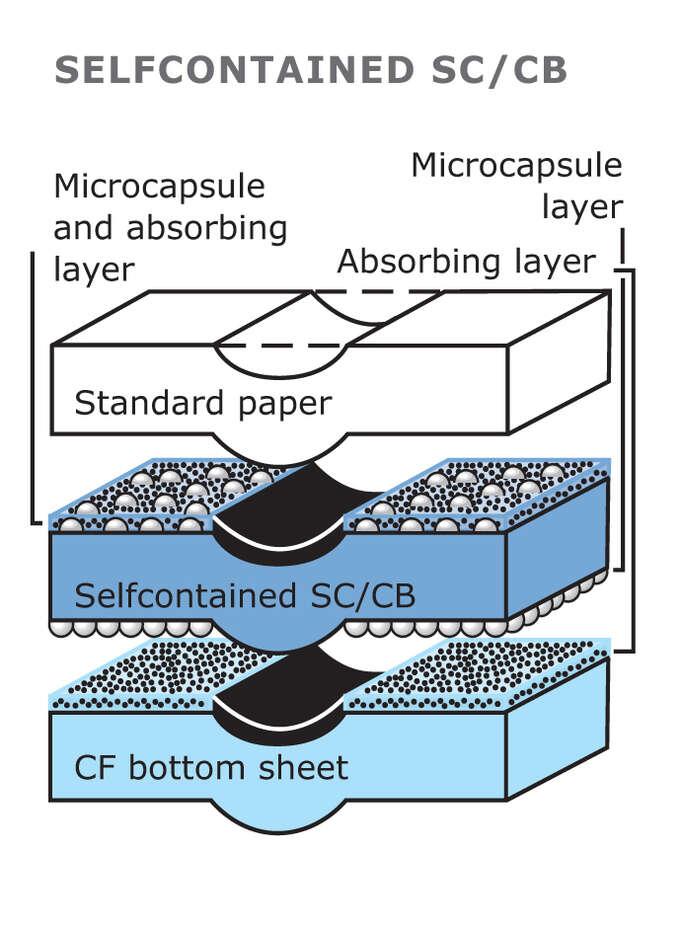

Self-Contained Carbonless Paper (SC and SC/CB)

Self-contained carbonless paper represents an innovative variant in the NCR family:

SC (Self-Contained): Contains both color-producing microcapsules and reactive clay on the same side of a single sheet. When pressure is applied, the capsules burst and react with the surrounding clay, creating a copy on the same sheet.

SC/CB (Self-Contained/Coated Back): Combines the self-contained technology with a CB coating on the reverse side, allowing it to function as both a receiver and transmitter for multi-part forms.

This technology proves invaluable when users need to create a duplicate with a standard paper top sheet or require specialized form configurations.

Carbonless Paper Rolls and Pads

For specialized business operations, carbonless paper is available in alternative formats:

Carbonless rolls: Designed for high-volume applications like point-of-sale systems and receipt printers, they enable businesses to generate multiple copies rapidly during transactions.

Bound pads and books: Feature carbonless sets bound at the edge, allowing one copy to remain permanently attached while others are detached and distributed. These provide excellent tracking capabilities for sequential documents like invoices or work orders.

Laser-Compatible vs Traditional NCR Paper

The evolution of printing technology necessitated advances in carbonless paper:

Traditional carbonless paper: Contains solvent-based chemicals in its microcapsules that can potentially damage laser printer components, including rollers, drums, and heating elements.

Laser-compatible carbonless paper: Utilizes non-solvent-based imaging capsules specifically formulated to withstand the high temperatures of laser printing without releasing harmful substances.

When implementing digital documentation systems, organizations must select laser-compatible versions to protect their equipment and ensure optimal print quality. This advancement has significantly expanded the versatility of carbonless forms in contemporary office environments.

What is Carbonless Copy Paper Used For

Carbonless copy paper is used in nearly every industry where multiple copies of the same document are needed instantly. Because it’s clean, efficient, and easy to use, businesses rely on it for record-keeping, transactions, and customer documentation.

The following table illustrates the primary applications of carbonless paper across different sectors:

| Industry | Common Applications |

| Retail & Services | Invoices, receipts, sales orders, tickets |

| Legal | Contracts, agreements, legal forms, affidavits |

| Healthcare | Patient intake forms, prescriptions, medical/dental charts |

| Logistics | Bills of lading, shipping manifests, delivery confirmations |

| Manufacturing | Purchase orders, inventory forms, quality control documents |

| Trades & Construction | Work orders, estimates, proposals, inspection reports |

| Hospitality | Guest receipts, order forms, reservation confirmations |

These industries rely on carbonless paper because it offers several crucial advantages:

Immediate verification: Both parties can receive an identical copy at the time of transaction

Legal documentation: They provide admissible evidence of agreements and transactions

Workflow efficiency: We can distribute copies to different departments simultaneously

Record retention: Organizations maintain accurate archives while providing copies to clients

For businesses processing high volumes of transactions daily, carbonless forms significantly reduce documentation time while ensuring accurate information transfer. They eliminate the need for photocopying or scanning documents after completion, streamlining operations in fast-paced environments.

Whether for financial records, service agreements, or inventory management, carbonless paper continues to play a vital role in business documentation despite advances in digital technology.

How to Use Carbonless Copy Paper

Using Carbonless Paper with a Pen

For handwritten forms, the following best practices apply:

Use a ballpoint pen rather than gel or felt-tip pens for optimal pressure transfer

Apply firm, consistent pressure when writing to ensure the microcapsules break properly

Place a firm surface underneath the form set to provide necessary resistance

For signatures on multi-part forms, press firmly to ensure transfer through all copies

When properly executed, handwritten information transfers clearly through all layers without requiring additional actions between sheets.

Printing on Carbonless Copy Paper

| Printer Type | Compatibility | Best For |

| Impact Printers | Excellent | High-volume business forms |

| Laser Printers | Requires special paper | Office documentation |

| Inkjet Printers | Not recommended | N/A |

When printing with laser printers, we must ensure:

Only use special laser-compatible carbonless paper

Adjust print quantity correctly (for duplicates, print two sheets; for triplicates, print three)

Collate sheets in the correct order after printing

Tips for Proper Loading in Printers

To avoid jams and ensure proper image transfer:

Load sheets individually rather than as pre-collated sets

Maintain proper sheet order: top (CB), middle (CFB), and bottom (CF)

Allow printed sheets to cool completely before collating

Store unused carbonless paper in a cool, dry environment to preserve coating integrity

Place cardboard beneath each set when filing to prevent unwanted pressure transfer

By following these guidelines, you can maximize the efficiency of your carbonless paper forms while maintaining professional document quality across all copies.

100% wood pulp White Pink Yellow NCR paper

How to Choose the Right Carbonless Copy Paper

Selecting the appropriate carbonless copy paper requires careful consideration of several key factors to ensure optimal performance for your specific business documentation needs. The right selection will enhance efficiency while maintaining professional document quality.

Determining Your Requirements

Begin by assessing the number of copies required for each transaction. Most businesses utilize 2-part to 4-part forms, though specialized applications may require additional copies. Remember that transfer quality diminishes with each subsequent copy, so we recommend limiting forms to 5-6 parts maximum for maintaining legibility.

| Number of Parts | Typical Configuration | Common Applications |

| 2-Part | CB-CF | Simple receipts, basic invoices |

| 3-Part | CB-CFB-CF | Invoices with customer, accounting, and file copies |

| 4-Part | CB-CFB-CFB-CF | Complex orders requiring multiple department copies |

Paper Quality Considerations

When selecting carbonless paper, evaluate these critical elements:

Paper weight: Standard carbonless forms use lightweight paper (around 20-24 lb) to ensure pressure transfers effectively through all copies

Color sequence: Traditional color sequences (white-yellow-pink-goldenrod) provide easy identification, but custom colors are available for specific organizational systems

Coating quality: Higher-quality coatings produce clearer copies and resist fading over time

For laser printing applications, ensure you select specifically formulated laser-compatible carbonless paper to prevent damage to your equipment and achieve optimal image transfer.

Cost-Benefit Analysis

While premium carbonless papers offer enhanced durability and image clarity, they command higher prices. Evaluate your documentation requirements—forms intended for long-term record-keeping justify investing in higher-quality paper, while temporary transaction records may not require the same durability standards.

Pre-printed forms offer convenience but limit flexibility, whereas blank carbonless paper allows for customization but requires proper printing expertise. Your choice depends on documentation frequency, design stability, and in-house printing capabilities.

Summary

Carbonless copy paper works through special chemical coatings. When you write on it, tiny ink capsules burst and react with clay on the sheet below.

It creates clean, instant copies without messy carbon sheets. Businesses use it for receipts, invoices, contracts, and medical forms.

Despite digital alternatives, carbonless paper remains popular for its simplicity and reliability. It provides immediate physical copies that don't require technology.