Views: 0 Author: Site Editor Publish Time: 2025-02-25 Origin: Site

Did you know that billions of paper cups are used worldwide each day? Yet few understand how they're made.

From morning coffee runs to quick water breaks, paper cups have become an essential part of our daily lives. Their convenience shapes modern consumer culture.

In this comprehensive guide, you'll learn every step of paper cup production. We'll explore manufacturing methods, sustainability challenges.

Sustainable forestry practices play a crucial role in paper cup production. Here's how manufacturers ensure responsible sourcing:

Managed Forest Selection

Trees are carefully chosen from certified sustainable forests

Each harvested tree is replaced with new plantings

Regular monitoring ensures forest health maintenance

Certification Standards

FSC (Forest Stewardship Council) certification guarantees responsible forest management

PEFC (Programme for Endorsement of Forest Certification) validates sustainable practices

Regular audits ensure compliance with environmental standards

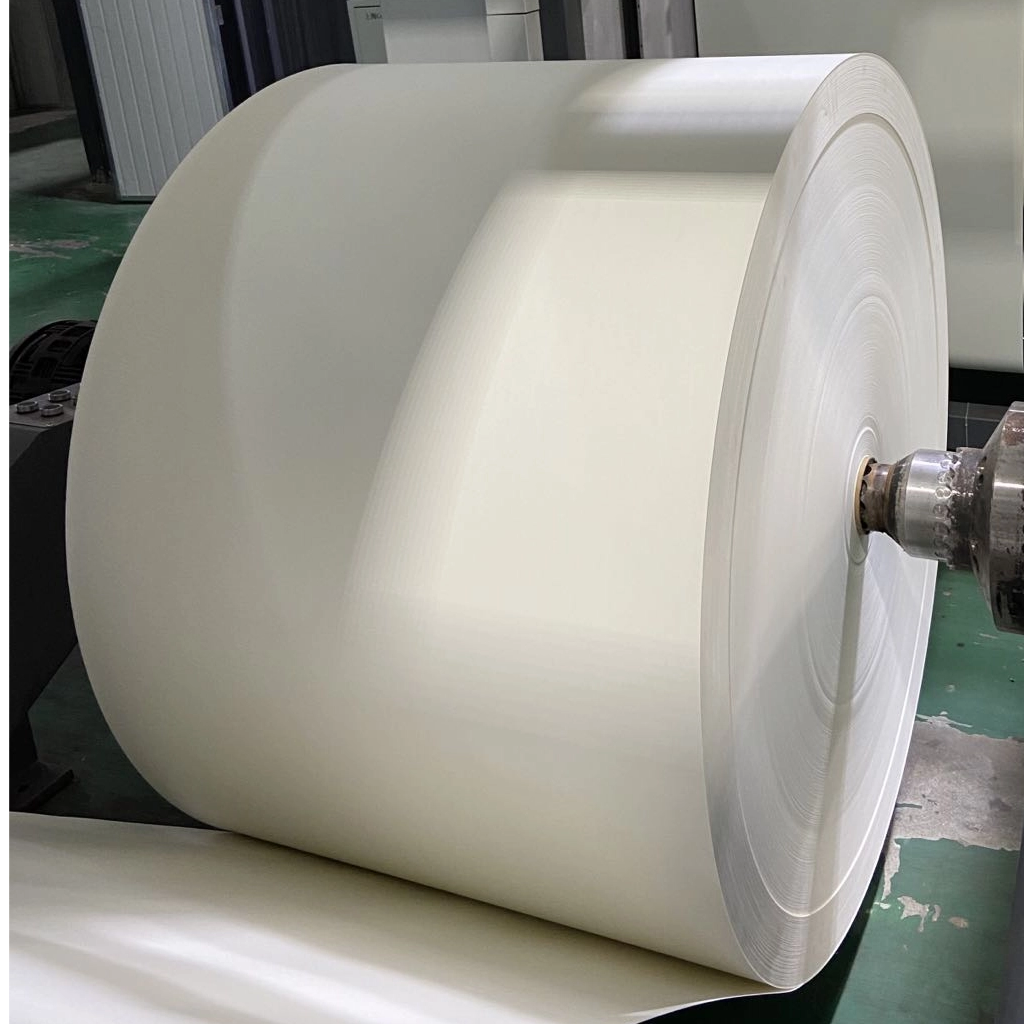

150-350g White PE Coated Paper cupstock Paper for Disposable Paper Cup

The manufacturing process requires specific materials to create safe, durable paper cups:

Core Materials Table:

| Material Type | Specifications | Purpose |

|---|---|---|

| Food-grade Paperboard | 0.3-0.5mm thickness | Main cup structure |

| PE Coating | 10-20 micrometers | Waterproofing |

| PLA (Alternative) | Plant-based material | Eco-friendly barrier |

Processing Steps:

Wood chips creation from harvested trees

Pulp transformation through cleaning and processing

Bleaching for desired whiteness

Conversion into food-grade paperboard

Additional Production Materials:

Food-safe adhesives for sealing

Eco-friendly printing inks

Specialized coating materials

Packaging materials for finished products

Through this careful selection and processing of raw materials, manufacturers create the foundation for safe, reliable paper cups while maintaining environmental responsibility.

The manufacturing of paper cups is a multi-stage process that transforms raw materials into durable, functional, and customizable beverage containers. From material preparation to final printing and packaging, each step plays a crucial role in ensuring the quality and sustainability of the final product. Below is a detailed breakdown of the key steps involved in the paper cup manufacturing process.

Before paper cups can be formed, the raw material—food-grade paperboard—must undergo several preparatory steps to ensure strength, cleanliness, and safety.

Cleaning and Pulp Transformation

The process begins with the transformation of wood into pulp. Wood chips are broken down using mechanical or chemical pulping methods. This ensures that the resulting fibers have the strength and flexibility necessary for cup production.

Bleaching Processes

To achieve the required whiteness and food safety standards, the pulp is bleached. This step removes any remaining impurities and enhances the final appearance of the cups.

Quality Control Measures

Stringent quality checks are conducted on the paperboard to ensure it meets regulatory food-contact safety standards. Parameters such as thickness, strength, and moisture content are assessed before the paperboard moves to the next stage.

A thin protective layer is applied to the paperboard to make it water-resistant, ensuring that the paper cups can hold both hot and cold beverages without leakage.

Coating Comparison Table:

| Coating Type | Properties | Environmental Impact | Durability |

|---|---|---|---|

| PE Coating | Waterproof, Heat-resistant | Standard impact | High |

| PLA Coating | Biodegradable, Natural | Low impact | Medium-High |

| Water-based | Eco-friendly, Flexible | Minimal impact | Medium |

PE (Polyethylene) Coating Application

The most common waterproofing method involves laminating a thin layer of polyethylene onto the paperboard. This enhances durability and prevents liquid from seeping through.

Eco-Friendly Coating Alternatives (PLA)

Many manufacturers are transitioning to PLA (Polylactic Acid) coatings, which are derived from renewable resources like cornstarch or sugarcane. Unlike PE, PLA coatings are biodegradable and compostable.

Waterproofing Techniques

Advanced coating methods ensure that the paper maintains its structural integrity even when exposed to hot liquids. Some innovations include water-based dispersion coatings, which provide an alternative to plastic-based coatings.

Once the coated paperboard is ready, it is cut into precise shapes that will later be formed into cups.

Die-Cutting Process

Large rolls of coated paperboard are fed into die-cutting machines, which cut the material into flat cup blanks. These blanks include both the sidewall panels and circular bottom pieces.

Size Specifications

The size and shape of each cup blank depend on the final cup specifications, including height, volume capacity, and diameter.

Material Optimization

To minimize waste, manufacturers use efficient nesting patterns when cutting the blanks. This reduces raw material usage and enhances cost-effectiveness.

The forming stage is where the paper blanks take their final shape, turning into functional cups.

Cup-Forming Machine Operation

Automated cup-forming machines take the pre-cut blanks and shape them into cylindrical forms. The machines precisely fold, seal, and press the materials together to ensure a tight, leak-proof structure.

Shaping Techniques

The sidewalls are sealed using heat sealing or ultrasonic bonding, ensuring a strong adhesion.

The bottom piece is attached separately and bonded to the sidewalls using a combination of heat and pressure.

Heat and Pressure Application

Controlled application of heat and pressure ensures that the seams are tightly sealed. This prevents leakage and enhances the cup’s durability.

To enhance the cup’s structural integrity and user experience, rim curling and bottom sealing are performed.

| Process | Function |

|---|---|

| Rim Curling | Strengthens the cup's edge and improves user comfort |

| Bottom Sealing | Ensures leak-proof performance by securely attaching the base |

| Leak Prevention | Uses heat and pressure to create a seamless connection |

Rim Curling Technology

The top edge of the cup is curled into a smooth, rounded shape. This makes it more comfortable to drink from and helps secure plastic lids.

Bottom Attachment Methods

The bottom section of the cup is inserted into place and bonded using heat and mechanical pressure.

This ensures a seamless and waterproof connection.

Leak Prevention Techniques

Manufacturers conduct leak tests by filling the cups with hot water and checking for seepage. Advanced techniques such as ultrasonic sealing further reinforce the bottom seal.

Customization and branding play a major role in the paper cup industry. Printing technology allows businesses to showcase their logos, designs, and marketing messages.

Printing Methods

Two common techniques are used to print on paper cups:

Flexographic Printing – Uses flexible printing plates to apply ink efficiently, making it suitable for large-scale production.

Offset Printing – Provides higher color accuracy and image sharpness, making it ideal for detailed graphics.

Customization Options

Brands can choose matte or glossy finishes, vibrant color schemes, and unique patterns to enhance their cup designs.

Brand Integration

Businesses often use paper cups as marketing tools by featuring their logos, promotional messages, or sustainability commitments directly on the cup.

Ensuring the quality of paper cups is essential for both consumer safety and brand reputation. Manufacturers implement rigorous quality control processes to verify that paper cups meet leak resistance, structural integrity, and food safety standards. This section outlines key testing procedures, industry standards, and certifications that ensure the reliability and sustainability of paper cups.

Paper cups undergo a series of quality tests to evaluate durability, safety, and performance before they reach the market. These procedures help identify potential defects, ensuring that every cup meets the highest manufacturing standards.

Leak prevention is crucial in paper cup manufacturing. Leak tests are conducted to verify that the cup's bottom seals and sidewalls effectively prevent liquid seepage.

Common Leak Testing Methods:

Hot Water Fill Test: The cup is filled with hot water to check for leaks under heat exposure.

Vacuum Leak Test: The cup is placed in a vacuum chamber to detect any seepage.

Pressure Test: Air or water is applied at varying pressures to identify weak points.

✅ Key Standard: A properly manufactured paper cup should hold liquid for a designated period without any leakage.

Paper cups must withstand physical stress without deforming or collapsing. Strength testing ensures the cup’s ability to maintain its structure during handling and usage.

| Test Type | Purpose | Expected Outcome |

|---|---|---|

| Compression Test | Measures resistance to external pressure | Cup should retain shape without crumpling |

| Drop Test | Simulates accidental drops during handling | No cracks or leaks |

| Stacking Load Test | Tests the strength of cups stacked on each other | No significant deformation |

These tests help ensure that the paper cups can handle storage, transportation, and consumer use without failure.

Since paper cups come into direct contact with beverages, they must meet food safety regulations. The following safety compliance checks are conducted:

✅ Chemical Safety Test: Ensures the materials used (paperboard, coatings, and inks) do not contain harmful chemicals.

✅ Temperature Resistance Test: Verifies that the cup maintains its form when holding hot or cold beverages.

✅ Odor and Taste Test: Confirms that no unwanted odors or flavors transfer to the drink.

Only cups that pass all safety tests proceed to the packaging stage.

To maintain consumer confidence, paper cup manufacturers must adhere to industry-wide certifications for food safety and environmental responsibility.

Paper cups must comply with food-grade safety regulations to ensure they are safe for drinking purposes.

Key Certifications & Regulatory Standards:

FDA (U.S. Food and Drug Administration): Ensures materials are safe for food contact.

EFSA (European Food Safety Authority): Governs food-safe materials in the EU.

GB Standard (China National Standards): Regulates food packaging safety.

Example: The coating applied inside the cup must not release toxic chemicals when exposed to heat.

Eco-conscious manufacturing is a priority, and paper cups must meet sustainability and recyclability standards.

| Certification | Purpose | Significance |

|---|---|---|

| FSC (Forest Stewardship Council) | Ensures paper materials are sourced from responsibly managed forests | Verifies sustainability |

| PEFC (Programme for the Endorsement of Forest Certification) | Promotes sustainable forest management for paper production | Supports eco-friendly sourcing |

| Flustix Plastic-Free Certification | Confirms plastic-free or reduced plastic content | Encourages biodegradable alternatives |

These certifications enhance brand credibility and meet consumer demand for greener packaging solutions.

To maintain consistency in production, manufacturers implement internal quality control protocols beyond regulatory requirements.

✅ Pre-Production Testing: Ensures raw materials (paperboard, inks, coatings) meet quality specifications.

✅ In-Process Inspection: Identifies defects during manufacturing, reducing waste.

✅ Final Product Inspection: Conducts random sampling to test cups for leaks, durability, and branding accuracy.

Paper cup production relies on various specialized machines designed for different manufacturing needs. The table below provides an overview of the most common types of paper cup manufacturing machines, their functions, and key advantages.

| Machine Type | Function | Key Advantages |

|---|---|---|

| High-Speed Paper Cup Forming Machine | Produces large volumes of paper cups at high speed. | Increases production efficiency, reduces labor costs, and supports mass manufacturing. |

| Automatic Paper Cup Forming Machine | Fully automated process for forming, sealing, and stacking paper cups. | Minimizes manual intervention, ensures consistency, and improves operational efficiency. |

| Semi-Automatic Paper Cup Forming Machine | Partially automated, requiring manual loading and unloading of materials. | Cost-effective for small to medium-scale production, flexible operation. |

| Single-Sided PE Coated Paper Cup Machine | Manufactures paper cups with a single-layer polyethylene (PE) coating for waterproofing. | Cost-effective, suitable for cold beverages and general-purpose cups. |

| Double-Sided PE Coated Paper Cup Machine | Produces paper cups with PE coating on both sides, enhancing insulation and leak-proof properties. | Ideal for hot beverages, improves durability. |

| Ultrasonic Paper Cup Forming Machine | Uses ultrasonic welding technology to bond seams for airtight and leak-proof joints. | Eliminates the need for heat sealing, enhances precision and reliability. |

| Flexographic Printing Paper Cup Forming Machine | Equipped with flexographic printing units to print logos, branding, and designs directly onto paper cups. | Allows for inline high-quality printing, saving time and resources. |

| High-Speed Double Wall Paper Cup Machine | Specially designed to produce double-walled paper cups, offering better insulation. | Suitable for hot beverages, ensures superior heat retention and hand comfort. |

Find answers to commonly asked questions about paper cup manufacturing, from production processes to environmental concerns.

Q: What are the main materials used in paper cup production?A: Paper cups primarily use food-grade paperboard (0.3-0.5mm thickness), with PE or PLA coating for waterproofing. Additional materials include food-safe adhesives and printing inks.

Q: How long does it take to manufacture a paper cup?A: Modern high-speed machines can produce thousands of cups per hour. The entire process from raw material to finished product typically takes several minutes per cup.

Q: What types of coating are used in paper cups?A: Manufacturers use:

Traditional PE (Polyethylene) coating

Eco-friendly PLA (Polylactic Acid) coating

Water-based dispersions

Biodegradable alternatives

Quality Testing Breakdown:

| Test Type | Purpose | Frequency |

|---|---|---|

| Leak Testing | Ensure water resistance | Every batch |

| Strength Testing | Verify structural integrity | Hourly samples |

| Safety Compliance | Check food safety standards | Daily checks |

| Material Quality | Confirm specifications | Each raw material batch |

Q: Are paper cups environmentally friendly?A: Modern paper cups can be:

Made from sustainably sourced materials

Produced with biodegradable coatings

Manufactured using energy-efficient processes

Designed for easier recycling

Q: What is the recycling rate for paper cups?A: Currently, about 0.25% of paper cups are recycled. However, new innovations and infrastructure improvements are increasing this rate.

Primary Cost Factors:

Raw Materials

Paperboard quality and type

Coating materials

Printing inks and adhesives

Production Expenses

Equipment investment

Energy consumption

Labor costs

Quality control measures

Volume Considerations

Minimum order quantities

Production scale efficiencies

Bulk purchase savings

Paper cups are made through cleaning, coating, cutting, forming, sealing, and printing. Machines automate each step, ensuring efficiency and consistency.

The industry is evolving with faster, high-precision machines. Demand for customized, high-quality cups is growing, especially in the food and beverage sector.

Environmental concerns drive biodegradable coatings and recyclable materials. Manufacturers are adopting eco-friendly solutions to reduce waste and carbon footprints.

Sunrise offers 20 years of OEM expertise, comprehensive certifications, and expansive manufacturing capacity across 50,000+ square meters. We serve customers in 120+ countries with reliable after-sales support. Contact Sunrise today to fulfill your paper and paperboard requirements.