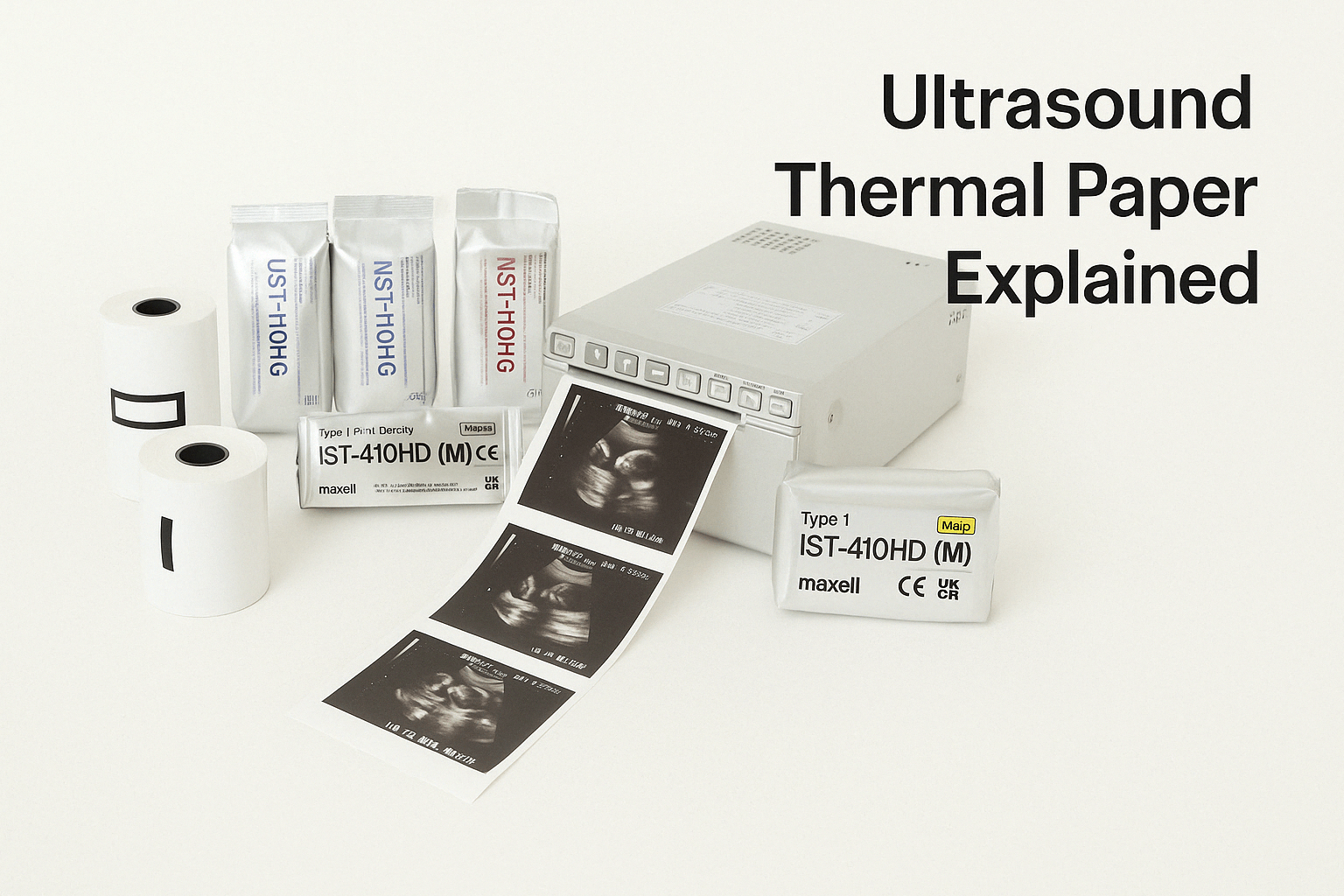

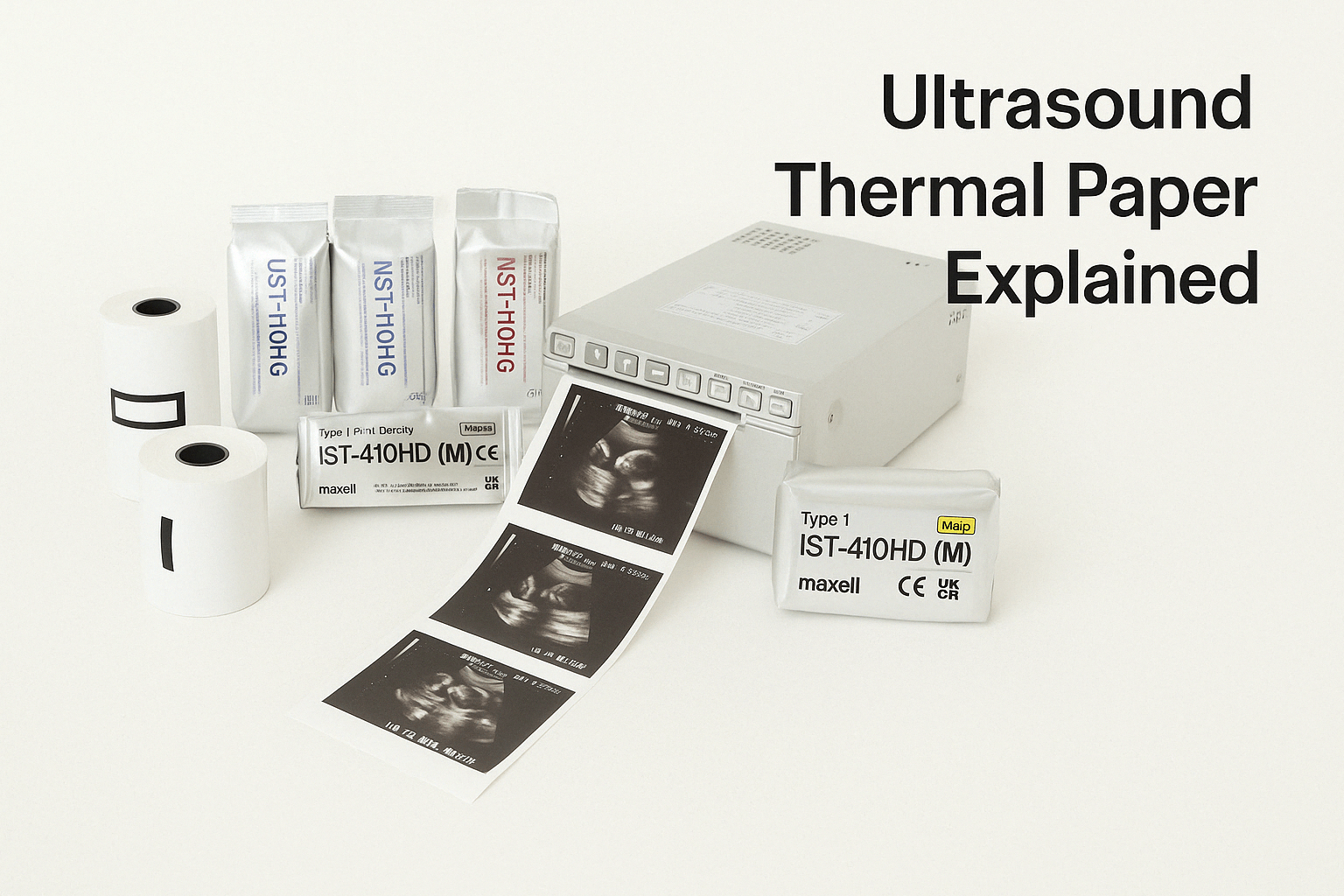

Ultrasound thermal paper plays a crucial role in capturing clear and lasting medical images—but what exactly is it, and why does it matter so much in healthcare? If you've ever wondered how ultrasound scans turn into crisp black-and-white prints, this is where the story begins.

In this post, you’ll learn what ultrasound thermal paper is, how it works in ultrasound machines, and why medical professionals rely on it. We’ll break down the types, uses, and how to choose the best one for your needs. Let’s explore this essential medical printing tool together.

What is Ultrasound Thermal Paper?

Ultrasound thermal paper is a type of heat-sensitive printing paper used in medical imaging. It reacts to heat from thermal printer heads, allowing ultrasound machines to create sharp black-and-white prints. This paper is specially designed for diagnostic purposes and isn’t the same as the thin thermal paper you see in receipts.

Key differences from standard thermal paper:

Made from synthetic base for durability

Higher resolution, long-lasting images

Designed for grayscale medical prints

| Feature | Ultrasound Thermal Paper | Standard Thermal Paper |

| Purpose | Medical imaging | Receipts, labels |

| Paper Weight (GSM) | 80–110 | 48–70 |

| Image Detail | High contrast, detailed grayscale | Basic black-and-white text |

| Longevity | 7–10 years | Fades in weeks or months |

Composition and Layer Structure

Ultrasound paper isn’t just one sheet—it’s built in layers. Each one does something important. There’s a glossy outer layer for clarity, a protective coating, and a thermal-sensitive layer underneath. Beneath all that? A flexible synthetic base and an anti-static shield.

5-layer structure:

High-gloss layer – Boosts contrast, resists smudges and fingerprints.

Top coat – Shields thermal coating from scratches and chemicals.

Thermal coat – The image shows up here when heat is applied.

Base material – Usually synthetic paper; strong but flexible.

Anti-static layer – Keeps dust away, improves printing accuracy.

How It Works

Here’s what happens during an ultrasound print. First, sound waves scan the body and bounce back as echoes. The machine turns these echoes into digital signals, which are processed into an image. That image goes to a thermal printer.

When the thermal printer receives data, it applies heat to specific spots on the thermal coat. This triggers a chemical reaction that reveals the grayscale image. Darker areas = stronger echoes.

Quick summary of the printing process:

Ultrasound captures internal echoes

Machine converts echoes to a digital image

Printer heats the thermal layer

Grayscale image appears on paper

Types of Ultrasound Thermal Paper

Standard Ultrasound Paper

This is the go-to choice for everyday scans. It’s often used in routine diagnostics where extreme image detail isn’t necessary. It still delivers solid, clear images—just not as sharp as the higher-end types. If stored well, these prints can last up to 7 years.

Best used for:

Key Features:

High-Density Ultrasound Paper

High-density paper gives better contrast. The printed images have sharper lines and deeper grays. This type is especially useful for specialists who need to see fine differences—like obstetricians tracking fetal development or cardiologists looking at heart detail.

When to use it:

Obstetric imaging

Cardiology diagnostics

Visual differences from standard paper:

| Feature | Standard Paper | High-Density Paper |

| Grayscale Range | Moderate | Wide and smooth |

| Detail Clarity | Basic diagnostics | Enhanced fine details |

| Lifespan | Around 7 years | Up to 10 years |

High-Gloss Ultrasound Paper

This one’s made for high-end printing needs. It has a shiny outer layer that resists water drops and fingerprints. Doctors often use it to print 3D or 4D ultrasound images. That polished finish helps preserve every tiny detail.

Great for:

Notable traits:

Comparison with Other Paper Types

Ultrasound Paper vs. Regular Thermal Paper

Ultrasound Paper

Ultrasound paper is specifically designed for high-resolution imaging, providing clear, long-lasting prints that maintain accuracy over time. It has a higher GSM, which contributes to its durability and smoothness. This makes it ideal for capturing detailed images required in medical diagnostics.

Regular Thermal Paper

Regular thermal paper is commonly used in receipts and tickets. It is not built for high-resolution printing, and its printouts can fade over time, especially when exposed to heat. The GSM is generally lower than ultrasound paper, making it less durable and less capable of handling detailed medical imaging.

Ultrasound Paper vs. Other Medical Printing Papers

Color Thermal Paper

Color thermal paper, used for endoscopy or surgery reports, differs from ultrasound paper in its purpose and print quality. While ultrasound paper is focused on clear black-and-white imaging for diagnostic purposes, color thermal paper is used to highlight specific areas in medical reports, offering multiple color options for visualization.

Black-and-White Paper

Black-and-white ultrasound paper is the standard in ultrasound imaging. It offers the sharp contrast and clarity needed for accurate medical diagnosis. In contrast, color paper used in other medical printing settings may not be able to provide the same level of precision required for ultrasound images.

Common Sizes and Compatibility

Standard Ultrasound Paper Sizes

A6, A7, A4 Width Formats: Common ultrasound paper sizes include A6, A7, and A4. A6 and A7 formats are used for portable devices, while A4 is typically preferred for large, stationary ultrasound machines.

Popular Models and Their Specifications: Some models of ultrasound machines, such as those from Sony and Mitsubishi, use A6 or A4-sized paper, depending on their design and functionality.

Printer Compatibility

Printer Model Examples: Sony, Mitsubishi, and other popular brands offer printers designed for ultrasound imaging. It's crucial to choose ultrasound paper that matches the printer's specifications for optimal print quality.

What to Check Before Choosing Paper: Before purchasing, always check the printer model’s recommended paper size and thickness. This ensures compatibility and prevents issues like paper jams or poor print quality.

How to Choose the Right Ultrasound Thermal Paper

Key Selection Factors

Image Resolution and Gray Scale Accuracy

When selecting ultrasound paper, image resolution and gray scale accuracy are essential. The paper should support high-resolution imaging to capture the fine details needed for accurate diagnoses. Gray scale accuracy ensures the paper can display a range of shades, allowing for precise visualization of structures. Poor resolution can lead to blurred or inaccurate images, which could affect diagnostic quality.

Key Points:

High resolution is crucial for clear imaging.

Gray scale accuracy helps visualize fine details.

Poor resolution leads to blurred, inaccurate images.

Paper Thickness (GSM) and Durability

Paper thickness, measured in GSM (grams per square meter), directly impacts both durability and print quality. Higher GSM paper is thicker, more durable, and less likely to fade or degrade over time. For medical ultrasound prints, paper with a higher GSM ensures that the images withstand repeated handling, storage, and environmental conditions. Thin paper may tear or become damaged easily, leading to compromised print quality.

| GSM Range | Durability | Print Quality |

| 50–60 GSM | Low | Basic quality |

| 70–80 GSM | Medium | Good quality |

| 90–100 GSM | High | Excellent quality |

Print Longevity: 7–10 Years Image Retention

A key factor in ultrasound paper selection is the longevity of the print. Ultrasound images need to be stored for long periods for medical records. The paper should retain its image quality for 7 to 10 years, ensuring that the prints remain legible and accurate even after long-term storage. Paper that fades quickly or deteriorates can cause loss of important diagnostic information.

Key Points:

Ensure a retention period of at least 7 years.

Choose paper that withstands aging and environmental factors.

Paper should maintain legibility for medical record purposes.

Considerations Based on Application

OB-GYN

For OB-GYN ultrasound imaging, paper with high resolution and a wide gray scale is necessary to clearly display the developing fetus. Detailed images are crucial for tracking growth, detecting abnormalities, and ensuring accurate diagnoses. Durability is also important since these prints may be referenced multiple times during the pregnancy or in follow-up visits.

| Requirement | OB-GYN Ultrasound Paper |

| Resolution | High resolution for clear imaging of fetal development |

| Durability | Paper must withstand frequent handling and long-term storage |

| Image Quality | Fine gray scale for accurate tissue and organ visualization |

Cardiology

Cardiology ultrasound requires precise imaging of the heart and vascular structures. The paper needs to provide excellent contrast and resolution for clear visualization of blood flow, heart valves, and arteries. These prints are often part of ongoing patient care, so durability is crucial to ensure that they remain intact and usable for reference over time.

| Requirement | Cardiology Ultrasound Paper |

| Resolution | High resolution for clear imaging of heart structures |

| Contrast | Strong contrast for clear blood flow and heart valve visualization |

| Durability | Paper should resist wear from frequent handling and storage |

General Imaging

For general ultrasound imaging, paper needs to balance cost and quality. While the resolution may not need to be as high as for OB-GYN or cardiology, clarity is still important for accurate diagnostics. The paper should provide sufficient detail for a wide range of conditions, from abdominal scans to musculoskeletal imaging.

Key Points:

Clear and sufficient resolution for a variety of imaging needs.

Balanced quality and cost for general applications.

Paper should be durable enough for regular handling.

Storage and Handling Guidelines

Before Use

Ideal Storage Temperature and Humidity

Ultrasound thermal paper should be stored in a cool, dry environment, ideally between 15°C to 25°C (59°F to 77°F). The humidity level must be kept below 50% to prevent moisture absorption, which could negatively affect the paper's print quality and longevity. Proper storage conditions help maintain the paper’s integrity for accurate imaging.

Protection from Physical and Chemical Exposure

Keep ultrasound paper away from direct sunlight, heat, and chemicals, as exposure to these elements can cause fading or chemical damage. Store the paper in its original packaging or protective containers to avoid physical damage, such as bending or creasing. This protection ensures the paper remains in optimal condition for printing clear ultrasound images.

After Use

How to Preserve Printed Ultrasound Images

To preserve printed ultrasound images, store them in a cool, dry location away from direct light or heat. Avoid stacking prints as this can distort the images. Use protective covers or folders to shield the prints from dust, moisture, and physical damage. Proper storage ensures the longevity of the images for future medical reference.

Tips to Avoid Fading, Curling, or Smudging

Handle ultrasound prints carefully to prevent fading, curling, or smudging. Always hold prints by the edges to avoid leaving fingerprints on the surface. If curling occurs, gently place the prints under a weight to flatten them. For long-term preservation, store the prints in sealed, dry conditions, away from environmental damage like heat and light.

Manufacturing and Quality Insights

How Ultrasound Thermal Paper is Made

The manufacturing of ultrasound thermal paper involves applying a thermal coating to the paper, which reacts to heat from the printhead to produce images. After coating, the paper is cut into rolls to fit various ultrasound printer models. Consistency in size and coating ensures high-quality prints.

Chemical uniformity is crucial in this process. An even distribution of the thermal coating ensures consistent image quality, preventing issues like fading or blotchy prints. Manufacturers focus on uniform chemical composition for reliable, sharp images.

Quality Control: What to Look For

Quality control involves testing the paper’s ability to produce clear grayscale images and resist moisture exposure without losing integrity. The paper is also tested for tear cleanliness to ensure it tears evenly. Additionally, smoothness is essential to protect the printer's printhead. High-quality ultrasound paper is smooth and consistent, minimizing friction and ensuring clear prints while preserving printhead longevity.

Troubleshooting Common Issues

Why Are My Ultrasound Prints Fading?

Heat and light exposure: Fading can occur if prints are exposed to heat or light for too long. Store prints in a cool, dark place to avoid this.

Low printer temperature: A low temperature setting on the printer can prevent a strong reaction with the paper, leading to faint prints. Adjust the temperature to the recommended level.

Low-quality paper: Poor-quality paper may fade more quickly. Always use high-quality ultrasound thermal paper for better image retention.

White Lines or Missing Areas in Print?

Printer-paper mismatch: Using incompatible paper can cause missing areas. Check the paper specifications to match your printer model.

Dirty or damaged printhead: A dirty printhead may cause white lines or gaps. Regularly clean and inspect the printhead for any damage.

Paper Curling After Printing?

Improper storage: Store ultrasound paper in a dry, cool place to avoid moisture absorption, which can cause curling.

High humidity: Humidity can warp the paper. Keep it in low-humidity environments to prevent curling.

Alternatives and Compatible Products

Generic vs. OEM Ultrasound Paper: Is There a Difference?

Generic ultrasound paper tends to be more affordable but may not meet the same quality standards as OEM products. OEM paper is specifically designed for certain printers, offering superior image clarity and consistency. While generic alternatives can work, they may lack the durability and compatibility of OEM options.

Are Compatible Alternatives Safe and Reliable?

Compatible alternatives can be safe and reliable when sourced from reputable brands. However, low-quality alternatives may cause issues like fading, poor image resolution, or damage to printers. Always ensure compatibility with your printer model to avoid problems.

Conclusion

Ultrasound thermal paper is key to sharp, lasting medical prints. Choose the right type for each use, and store it properly to avoid damage. Match paper with printer models to reduce issues like fading or curl—small steps, big results in clinical accuracy.

Stick with trusted paper for smooth printing and safe equipment use. Whether OEM or compatible, test first for clarity and durability. Want better image quality and fewer reprints? Start with the right paper—it's a simple move that makes a difference every time.

Frequently Asked Questions

What is ultrasound thermal paper used for?

It’s used to print diagnostic images during ultrasound exams, especially in OB-GYN, cardiology, and general imaging.

Can I use regular thermal paper in an ultrasound printer?

No. Regular thermal paper lacks the resolution, coating, and durability needed for ultrasound printer compatibility.

How long do ultrasound prints last?

Most ultrasound prints last 7 to 10 years when stored properly—away from heat, light, and humidity.

Reference Sources

[1] http://ustinc.co.kr/?page_id=834

[2] https://pandapaperroll.com/ultrasound-thermal-paper-the-complete-buy-guide/

[3] https://pandapaperroll.com/ultrasound-thermal-paper-101/

[4] https://www.jpihealthcare.com/products/protection-consumables/ultrasound-thermal-paper/

[5] https://easytrace.deasnet.it/medical-print-media/

[6] https://edusofthealth.com/ultrasound-thermal-paper.php