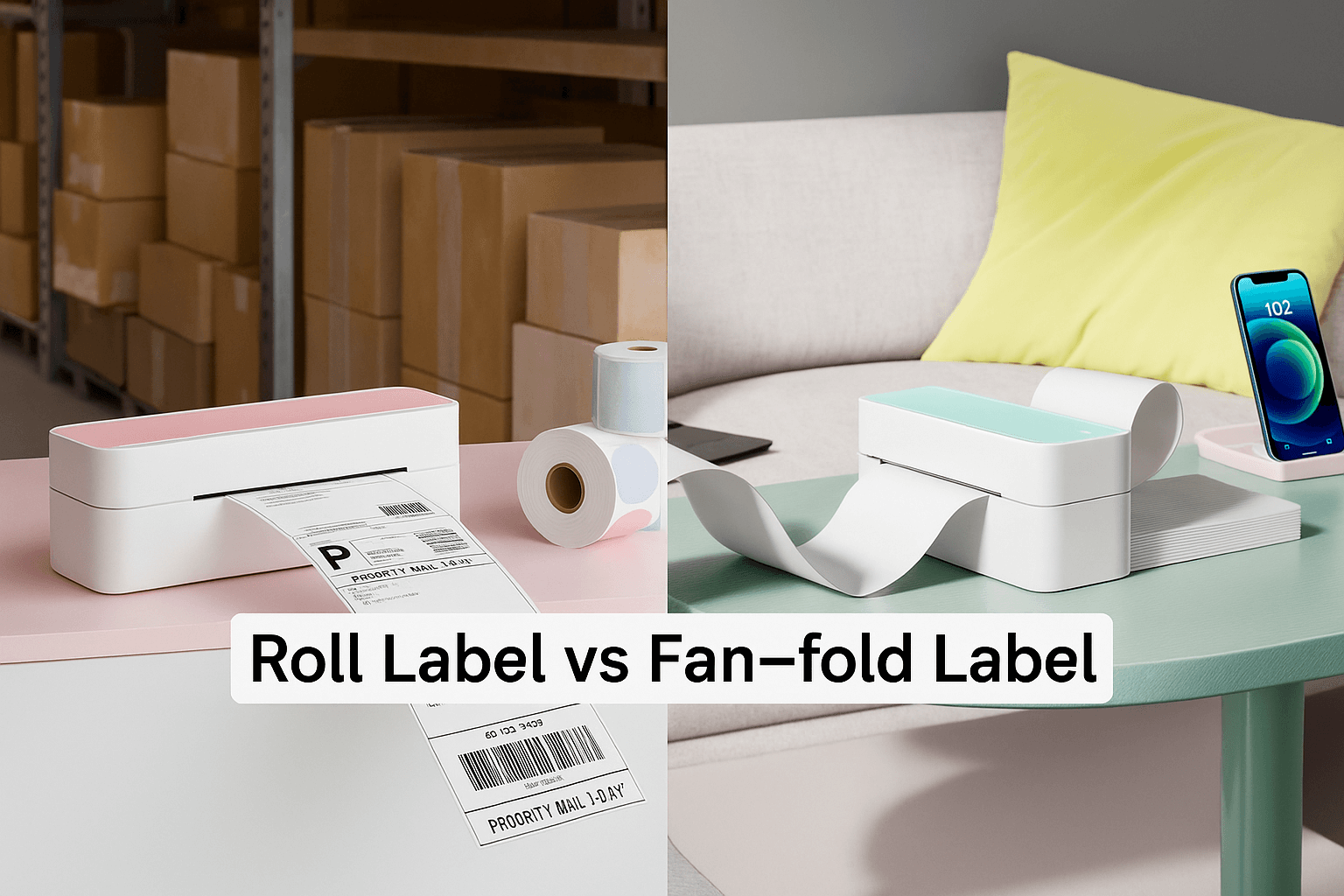

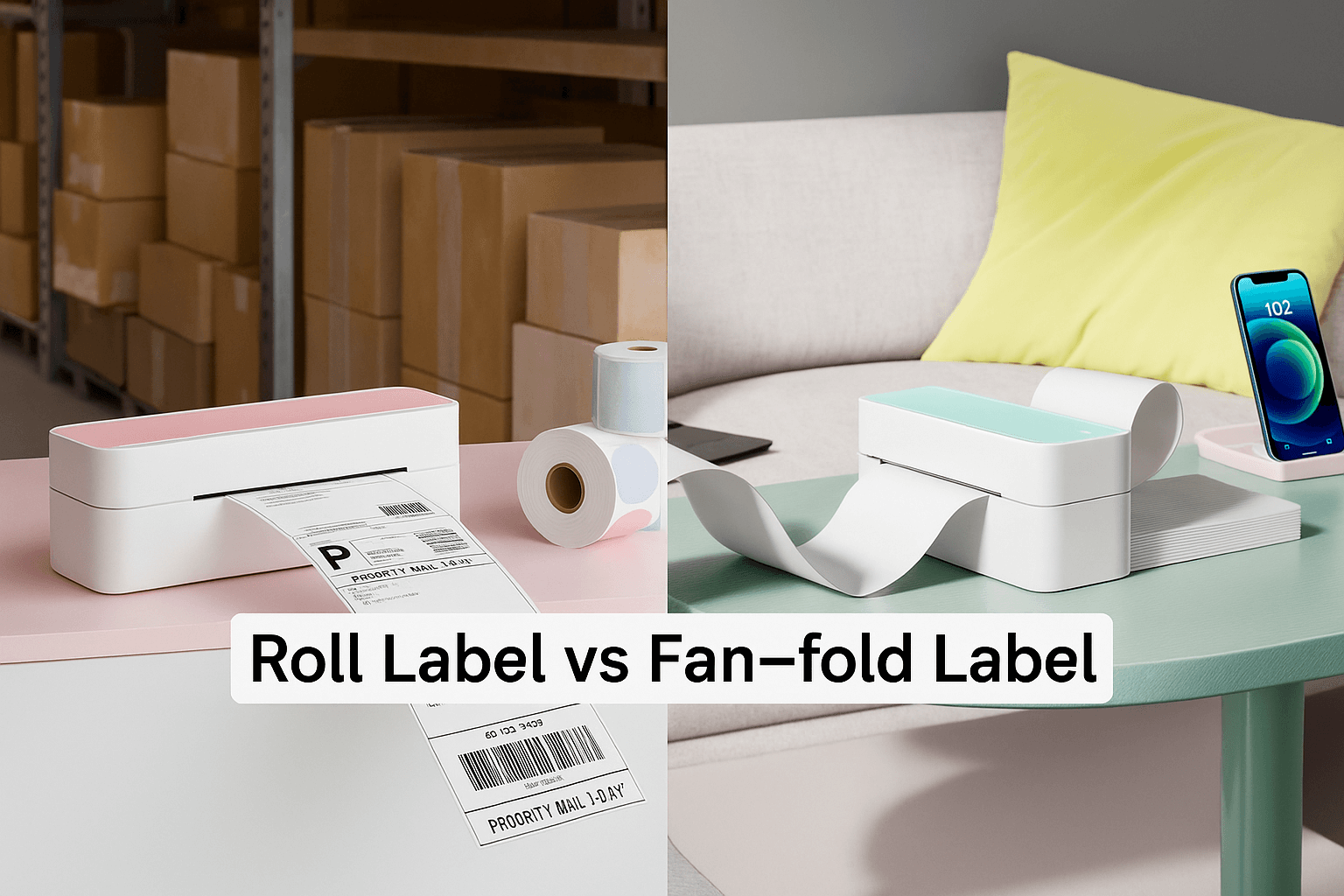

Roll labels and fanfold labels are two of the most popular thermal label formats—but which one is right for you? Whether you’re managing a warehouse or shipping products from home, choosing the wrong label type can affect print quality, storage space, and workflow efficiency.

In this post, we’ll explore the key differences between roll labels vs fanfold labels. You’ll learn about printing speed, cost, compatibility, and more—so you can confidently pick the best option for your business needs.

What Are Roll Labels?

Roll labels are labels wound around a cardboard core, forming a cylinder. They're one of the most common label formats used in thermal printing. You’ll find them in shipping, retail, and many other industries. Their shape allows for easy feeding into printers, especially where space is limited or speed is critical.

How Roll Labels Are Made

Roll labels are created by printing or cutting label material onto a continuous liner. That liner is then wound tightly around a paperboard or plastic core. The size of the core varies based on printer compatibility. Because the labels stay on the liner, they feed smoothly into the printer without peeling.

How Roll Labels Work in Printers

Thermal printers pull the label roll from the core and feed it through the print head. Most desktop models have internal holders that support rolls directly, while larger operations may use external mounts. The roll unwinds as labels are printed, and the backing is discarded or rewound depending on the setup.

Printer Compatibility Overview

| Printer Type | Roll Label Compatibility |

| Direct Thermal Printers | ✔️ Commonly used |

| Thermal Transfer Printers | ✔️ Requires ribbon |

| Inkjet/Laser Printers | ❌ Not suitable |

Common Core Sizes and Label Dimensions

Roll labels come in a wide range of sizes. The core size affects which printer they fit into. Outer roll diameter also determines how many labels a roll can hold. Typical configurations balance between size, capacity, and printer model compatibility.

Standard core diameters: 1 inch, 1.5 inch, 3 inch

Common roll sizes: 4" x 6", 2" x 1", 4" x 2"

Label Roll Specs Table

| Core Size | Outer Diameter | Labels per Roll (Approx.) |

| 1 inch | 4–5 inches | 250–1,000 |

| 3 inch | 8 inches | 2,000–5,000 |

Industries and Use Cases for Roll Labels

Roll labels are everywhere—from storefronts to factories. They're fast, easy to reload, and compatible with many printers. Their cylindrical shape works well in compact setups, making them a go-to for many businesses.

Shipping and Logistics: For printing high volumes of address or tracking labels quickly.

Retail: Price tags, barcodes, or promotional stickers printed on-demand.

Healthcare: Patient ID labels, lab sample tracking, and prescription labels.

Food Services: Expiry date labels, product IDs, and inventory tags.

What Are Fanfold Labels?

Fanfold labels are continuous labels stacked in a zigzag pattern, like an accordion. They're commonly used in high-volume printing setups. Unlike roll labels, they don’t use a core and are designed to sit flat behind or beside the printer, feeding in smoothly during operation.

The Structure of Fanfold Labels (Accordion-Fold Design)

Each label in a fanfold stack is connected by perforated edges. The liner folds back and forth to create a neat, compact block. This stack stays flat, which prevents curling and helps labels come out straight. It’s easy to store and can hold thousands of labels in one pile.

How Fanfold Labels Feed Through Printers

Fanfold labels are placed behind the printer. They’re fed through a rear or bottom slot into the print path. As the printer works, the labels self-stack on the other side. This means you don’t need to stand there and catch them—perfect for multitasking environments.

Feeding Process Snapshot

| Feature | Description |

| Loading Method | Rear or bottom feed slot |

| Movement Type | Continuous, folded through feed mechanism |

| Post-print Stacking | Self-stacking without manual intervention |

| Printer Type | Desktop or industrial thermal printers |

Typical Label Sizes and Stack Quantities

Fanfold labels come in various sizes, just like roll labels. The difference? You’ll get more labels in a single stack because there's no core. This means fewer reloads and longer runs before replacements are needed.

Common label sizes: 4" x 6", 2" x 1", 4" x 2"

Stack quantities: 500 to 2,000+ labels per pack

Fanfold Label Stack Examples

| Label Size | Labels per Stack | Notes |

| 4" x 6" | 500–2,000 | Most popular shipping size |

| 2" x 1" | 1,500–3,000 | Great for inventory tags |

| 4" x 2" | 1,000–2,500 | Used in logistics systems |

Industries and Use Cases for Fanfold Labels

Fanfold labels shine in large-scale operations. Because they allow long print jobs without constant reloading, they’re a favorite for organizations that need efficiency and simplicity in bulk printing tasks.

Warehousing: Inventory and asset tracking where uninterrupted printing is critical.

Logistics: Batch shipping label printing that keeps packing stations moving smoothly.

Manufacturing: Component labeling and batch ID tags printed in large runs.

Offices: Document tracking and file organization with unattended printing setups.

Key Differences Between Roll Labels and Fanfold Labels

Roll labels and fanfold labels may look similar on the surface, but their differences become obvious when you start using them. Let’s explore the specific ways they differ so you can choose what works best for your business.

Form Factor and Handling

Roll Labels

Come in a cylindrical shape, wound around a cardboard core.

Fit easily into printers with built-in holders or on external spindles.

Compact for individual use but can roll around during storage or setup.

Fanfold Labels

Folded in a zigzag, accordion-like stack without a core.

Sit flat behind or beside the printer and feed through a rear or bottom slot.

Stay organized and don’t roll away, but require more surface space.

Printing Speed and Efficiency

Roll Labels

Designed for continuous, high-speed printing, especially in auto-dispensing setups.

Ideal for short-run printing tasks that need to be fast and frequent.

Require more frequent reloading, especially with smaller rolls.

Fanfold Labels

Slightly slower on some printers but perfect for long, uninterrupted print jobs.

Hold more labels in a single stack, reducing reload interruptions.

Ideal for hands-free printing where operators focus on other tasks.

Curling and Label Flatness

Roll Labels

Prone to curling at the edges due to their tightly wound shape.

Curling can affect scanner readability or manual application.

Especially noticeable near the end of the roll.

Fanfold Labels

Stay completely flat because they’re not rolled or under tension.

Easier to peel, apply, or scan without needing adjustment.

Great for surfaces that require smooth label adhesion.

Waste Generation and Material Handling

Roll Labels

Include a cardboard core and extra packaging, which adds to waste.

Spent rolls must be removed and discarded after each use.

Handling can be messier, especially in high-volume environments.

Fanfold Labels

Coreless design produces less material waste.

Packaged densely, which reduces storage waste and improves organization.

Easier to transport and restock without bulky empty rolls.

Storage and Transportation Considerations

Roll Labels

Take up more vertical space and don’t stack well.

Cylindrical shape makes bulk storage less space-efficient.

Best stored in tall shelves or cabinets with supports.

Fanfold Labels

Stack flat in boxes, making them easy to store and ship.

Fit well in wide storage areas like drawers or flat shelves.

Less likely to shift or get damaged during transport.

Printer Compatibility

Types of Printers That Support Roll Labels

Direct thermal vs thermal transfer

Direct thermal printers generate images through heat, making them ideal for roll labels in applications like shipping. Thermal transfer printers use a ribbon to print on the label, providing more durability and longer-lasting results for certain types of labels.

Built-in vs external media holders

Roll labels are often used in printers with built-in media holders for smaller jobs. For larger rolls or high-volume tasks, external media holders are needed to accommodate bigger rolls and ensure continuous, efficient printing.

Types of Printers That Support Fanfold Labels

Feeding mechanisms for fanfold labels

Fanfold labels require specific feeding mechanisms, such as rear or side feed slots. These ensure that the labels feed correctly into the printer, allowing for smooth, continuous printing.

Limitations of compact or mobile printers

Mobile or compact printers, designed for portability, may struggle with fanfold labels due to their bulkier size. These printers are typically optimized for roll labels and may lack the capacity to handle fanfold labels effectively.

Label Application Considerations

Manual vs Automatic Label Application

Manual application

Roll labels are easier to handle manually due to their compact size and ability to be easily torn off. They are often used in small-scale operations where speed isn't a critical factor.

Automatic application

Automatic systems work better with fanfold labels as they feed continuously without the need for roll changes. This allows for faster, uninterrupted labeling in high-volume environments.

Which Format Works Better for Auto Dispensers?

| Feature | Roll Labels | Fanfold Labels |

| Feeding mechanism | Smooth, continuous feed | Can cause jams due to rigid format |

| Efficiency | Ideal for quick, high-speed dispensing | Slower and prone to interruptions |

| Preferred use | High-speed automatic dispensers | Limited use in automatic dispensers |

Effects on Print Alignment and Accuracy

Roll labels

Roll labels typically offer better alignment as they move smoothly through the printer, ensuring consistent and accurate printing.

Fanfold labels

Fanfold labels can face slight misalignments during printing due to their stacked nature, which may lead to occasional shifts and slight inaccuracies in print quality.

Cost Comparison

Cost per Label: Roll vs Fanfold

| Feature | Roll Labels | Fanfold Labels |

| Cost per label | Generally lower per label, ideal for large volumes | Slightly higher due to the need for more material |

| Bulk purchase | More cost-effective in bulk | Less efficient in bulk buying |

Long-Term Operational Costs

Labor

Roll labels often require less labor to handle, reducing manual efforts. Fanfold labels, due to their continuous form, may need more attention during application, increasing labor costs over time.

Reload frequency

Roll labels need fewer reloads due to their continuous feed, while fanfold labels require more frequent reloading, increasing operational downtime.

Maintenance and jams

Fanfold labels may cause more printer jams due to their stacking and rigid format, leading to higher maintenance costs over time compared to roll labels.

Storage and Shipping Costs

Roll labels are easier to store and ship due to their compact size and ability to be stacked tightly. Fanfold labels take up more space, leading to higher shipping and storage costs.

Which Label Type Is Right for Your Business?

Questions to Ask Before Choosing

How many labels do you print per day?

High-volume businesses printing hundreds or thousands of labels daily may benefit from roll labels for their efficiency, while lower volumes may be fine with fanfold labels.

Do you need unattended or high-speed printing?

If you require high-speed or unattended printing, roll labels are a better choice due to their continuous feed, which minimizes downtime and manual intervention.

How much space is available near the printer?

Roll labels take up less space and are easier to store, making them ideal for businesses with limited storage or workspace near the printer.

Scenario-Based Recommendations

Small businesses with limited space

Roll labels are best for small businesses due to their compact size and ease of use in environments with limited storage or workspace.

Warehouses with bulk shipping needs

Fanfold labels suit warehouses with high-volume shipments, as they allow for continuous printing without frequent reloads, supporting large-scale operations.

Multi-tasking environments with low supervision

In environments where workers are managing multiple tasks, roll labels provide a smoother, more efficient process, reducing the need for constant supervision and handling.

Pros and Cons Summary Table

| Feature | Roll Labels | Fanfold Labels |

| Print Speed | High | Medium |

| Label Curling | Common | Rare |

| Space Efficiency | Compact | Bulkier |

| Cost per Label | Slightly Higher | Lower |

| Waste Production | More | Less |

| Printer Compatibility | High | Medium |

| Refill Frequency | Moderate | Low |

| Unattended Printing | No | Yes |

How to Transition Between Formats

Can One Printer Support Both?

Some printers can support both roll and fanfold labels, but they require different media handling mechanisms. Printers equipped with adjustable media holders or those designed for multi-format support are ideal for this transition. However, always check your printer's specifications before switching.

Tips for Switching from Rolls to Fanfolds

Ensure your printer can handle fanfold labels and adjust settings for proper alignment.

Consider storage space for fanfold labels as they take up more room compared to rolls.

Train operators to handle the new format, especially if automated systems are involved.

Mistakes to Avoid When Switching Label Formats

Don’t ignore printer compatibility; always verify your printer’s media handling capabilities before making the switch.

Avoid underestimating the time required for adjustments in workflows.

Ensure proper label alignment during the transition to avoid printing errors.

Common Myths About Roll and Fanfold Labels

“Roll labels are always better for speed.”

While roll labels are typically faster, fanfold labels can also perform efficiently depending on your printer setup.

“Fanfold labels jam more easily.”

Jams are possible with both formats, but proper handling and printer adjustments can reduce jams for fanfold labels.

“You need special printers for fanfold labels.”

Most modern printers support both roll and fanfold labels with minor adjustments.

Conclusion

When choosing between roll and fanfold labels, consider your specific business needs and printing setup. Focus on factors like label volume, printer compatibility, and space efficiency. Operational efficiency should drive your decision, not just popularity, ensuring smoother workflows for your business.

Assessing your daily operations will help determine whether roll or fanfold labels suit your needs. Prioritize efficiency, cost-effectiveness, and space-saving solutions. Select the format that aligns best with your printing volume and business goals for optimal performance and long-term success.

FAQs

What is the main advantage of using fanfold labels over roll labels?

Fanfold labels are easier to store and handle, especially in environments with limited space.

Can fanfold labels be used in all thermal printers?

Most thermal printers can support fanfold labels, but it depends on media handling capabilities.

Do roll labels always cause curling?

Roll labels are more prone to curling, but proper storage and handling can reduce this issue.

Are fanfold labels more cost-effective for bulk printing?

Fanfold labels often cost less for bulk printing, especially with low-volume or high-usage applications.

Reference Sources

[1] https://www.enkoproducts.com/articles/fanfold-labels-vs-roll-labels/

[2] https://pandapaperroll.com/roll-labels-vs-fanfold-labels-differences/

[3] https://phomemo.com/blogs/news/roll-label-vs-fan-fold-label-what-one-is-better

[4] https://www.onlinelabels.com/articles/fanfold-labels-vs-roll-labels

[5] https://labelsontime.com/advantages-fanfold-thermal-labels

[6] https://www.reddit.com/r/Flipping/comments/18rrr0p/rollo_printer_users_do_you_use_fanfold_labels_or/

[7] https://labelwarehouse.com.au/blog/printing-solutions-fanfold-labels-vs-roll-labels/

[8] https://www.thermallabels.com.au/should-i-choose-rolled-or-fan-fold-thermal-labels

[9] https://impack.co/blogs/news/fan-fold-vs-roll-labels

[10] https://www.youtube.com/watch?v=u7lSebTksBQ