Choosing the right material for your packaging can make or break the first impression. Duplex Board vs Ivory Board—what’s the real difference, and why should it matter to your business?

Whether you're designing a cosmetic box, a food carton, or a premium brochure, understanding the strengths and uses of each paperboard type is essential. In this post, you'll learn the key differences between Duplex Board and Ivory Board, how they perform in packaging and printing, and which one suits your needs best.

Understanding the Basics of Paperboard

What is Paperboard?

Definition and General Characteristics

Paperboard is a thick, paper-based material that's stronger and more rigid than ordinary paper. It's often made by compressing layers of pulp into a dense sheet. People use it to make things like boxes, cards, and printed packaging. Its surface can be coated or uncoated depending on what it's meant for. Thickness usually starts above 250gsm, giving it stiffness and shape.

How It's Different from Regular Paper

| Feature | Regular Paper | Paperboard |

| Thickness | < 200gsm | ≥ 250gsm |

| Structure | Single layer | Multi-layer |

| Use Cases | Documents, newspapers | Packaging, covers |

| Durability | Low | High |

| Flexibility | Very flexible | Semi-rigid to rigid |

Why Paperboard Matters in Packaging

Impact on Durability, Printing, Product Safety

It resists bending and tearing, especially during shipping and stacking.

The smooth surface allows high-resolution images and detailed branding.

Some types, like Ivory Board, meet hygiene standards for food contact.

Common Industries Using Paperboard

Cosmetics & Skincare: For elegant, firm boxes that feel premium in hand.

Electronics: Used for protective yet presentable phone and gadget boxes.

FMCG Products: Think toothpaste, cereal, detergent—packaged in sturdy printed cartons.

Pharmaceuticals: Medicine boxes require both durability and print clarity for safety labels.

What is Duplex Board?

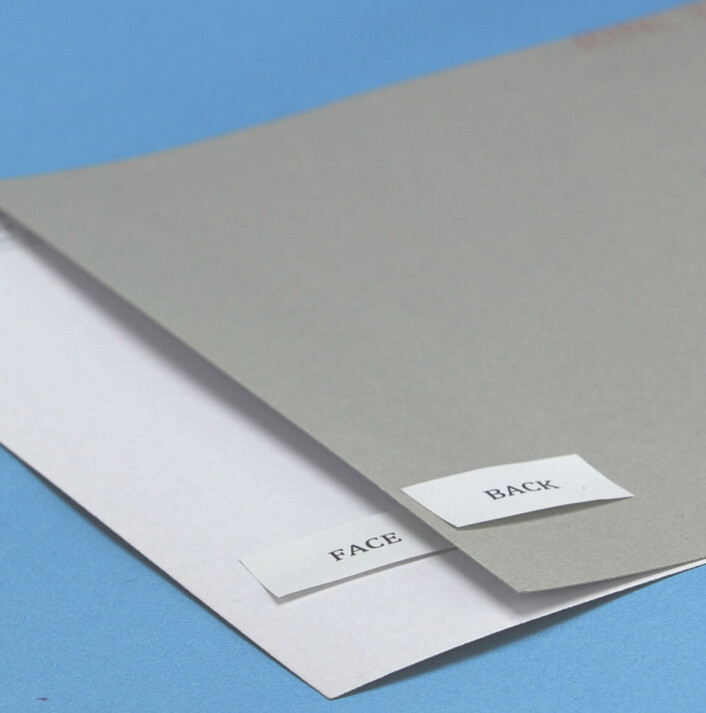

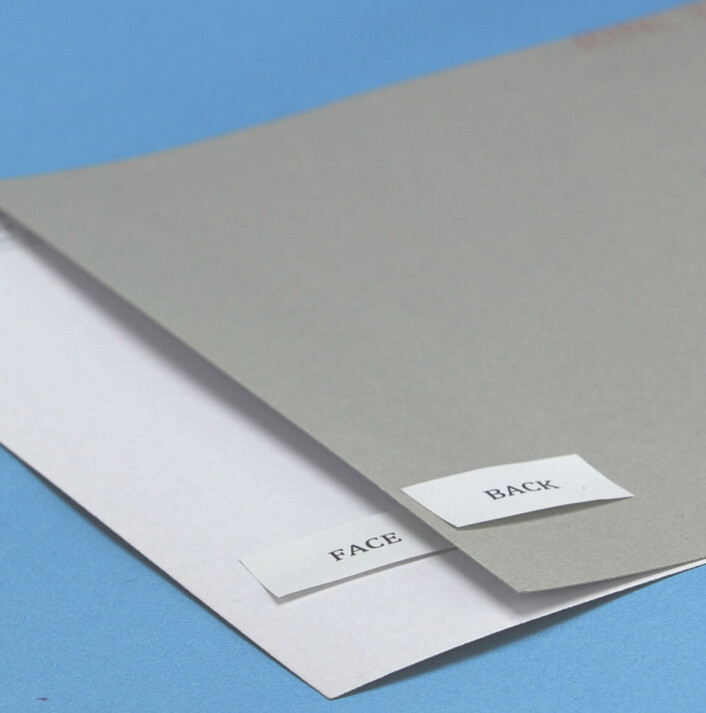

Composition and Structure

Duplex board is made by layering paper pulp, often from recycled sources. One side is coated—usually white and smooth—for better printing. The other side is uncoated, usually grey or dull white, helping reduce costs. This dual surface design balances appearance and practicality.

| Layer | Material Type | Function |

| Top Layer | Coated white pulp | Smooth surface for printing |

| Core Layer | Recycled mixed pulp | Adds thickness and stiffness |

| Bottom Layer | Grey or uncoated pulp | Lowers cost, adds structural support |

Key Characteristics

Strength and Stiffness

Duplex board can hold shape well under pressure. It doesn’t fold or tear easily, making it suitable for boxes that need to stay firm during shipping.

Cost-Efficiency

Using recycled pulp, duplex board is affordable, making it a solid choice for bulk packaging while maintaining functional and design value.

Surface Coating and Printability

The coated side allows high-resolution prints, ideal for retail-facing designs. The uncoated side adds stability but doesn’t print well.

Common Applications

Food Packaging: Used for cereal boxes, bakery containers, frozen food cartons, and takeaway packaging due to its moisture resistance.

Pharmaceutical Packaging: Often used for medicine packaging due to its ability to hold print and display critical information.

Electronics and FMCG Product Boxes: Common for phone accessories, gadgets, and daily-use items like soap or detergent.

Promotional Displays and Commercial Printing: Ideal for retail tags, calendar bases, and promotional items requiring a sturdy base and professional finish.

What is Ivory Board?

Composition and Structure

Ivory board is made from fully bleached virgin wood pulp, not recycled fiber, giving it a clean, consistent look. Both sides are coated—usually with a fine clay layer—so it’s smooth, bright, and ready for high-quality printing.

| Feature | Ivory Board |

| Pulp Source | 100% virgin pulp |

| Surface | Coated on both sides |

| Whiteness Level | Very high, visually clean |

| Texture | Uniform, smooth, low-porosity |

Key Characteristics

High Rigidity and Folding Strength

Ivory board feels thick and strong. It holds shape even under pressure, making it perfect for detailed box designs and layered cards.

Superior Print Surface and Smoothness

Smooth surfaces allow precise printing, resulting in sharp, vibrant colors. It’s ideal for designs requiring high image reproduction accuracy.

Hygienic, Food-Safe, and Premium-Grade

Made from virgin pulp, it’s safe for food or skincare contact. Its clean finish gives packaging a luxurious appearance, perfect for premium products.

Common Applications

Luxury Packaging: Used for perfume, skincare, and chocolate packaging due to its sturdy feel and elegant surface.

Premium Paper Bags and Boxes: Ideal for shopping bags, gift boxes, and retail packaging due to its strength and bright surface.

Business Cards, Certificates, Invitation Cards: Provides a clean, professional finish and supports embossing, foil stamping, and specialty inks.

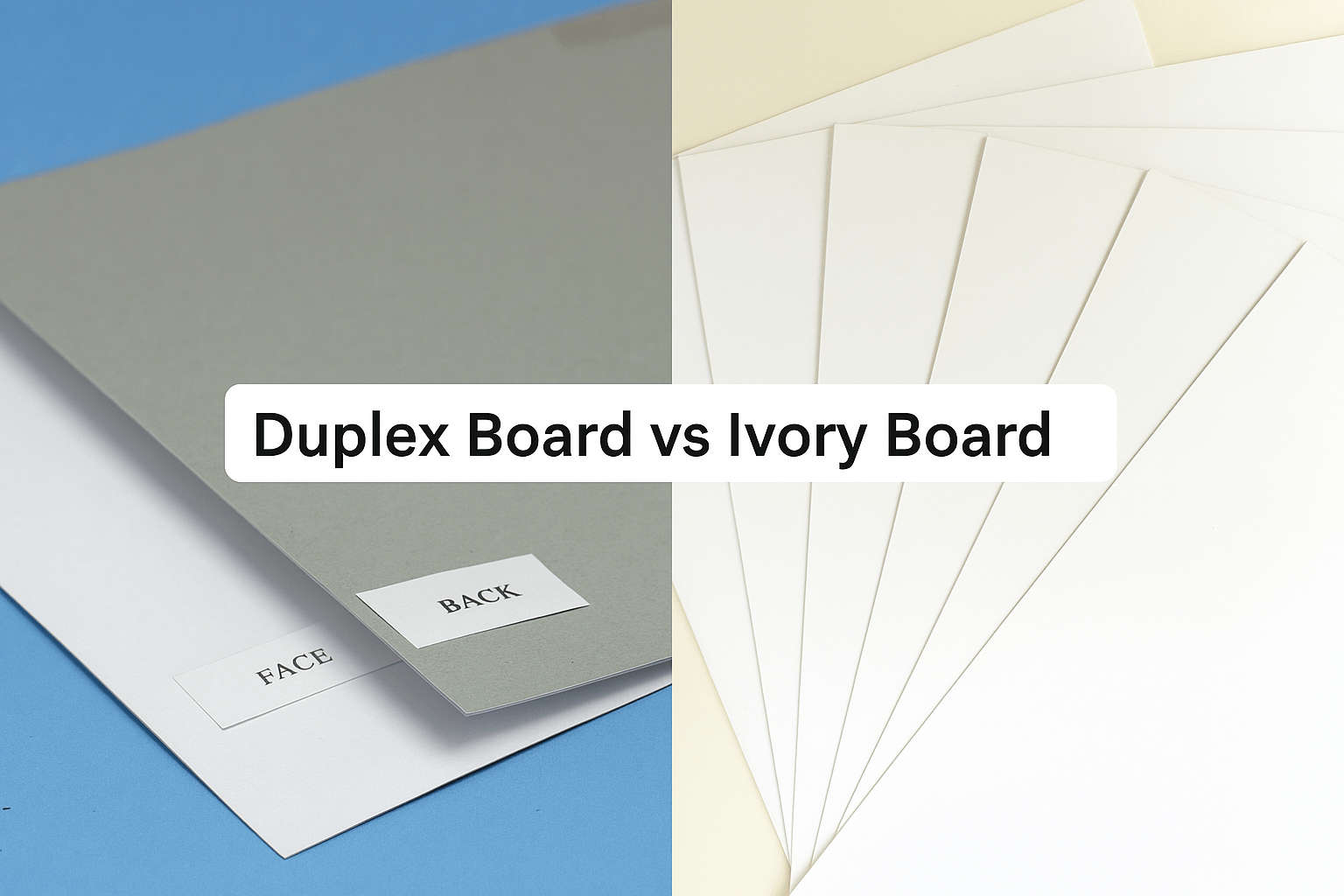

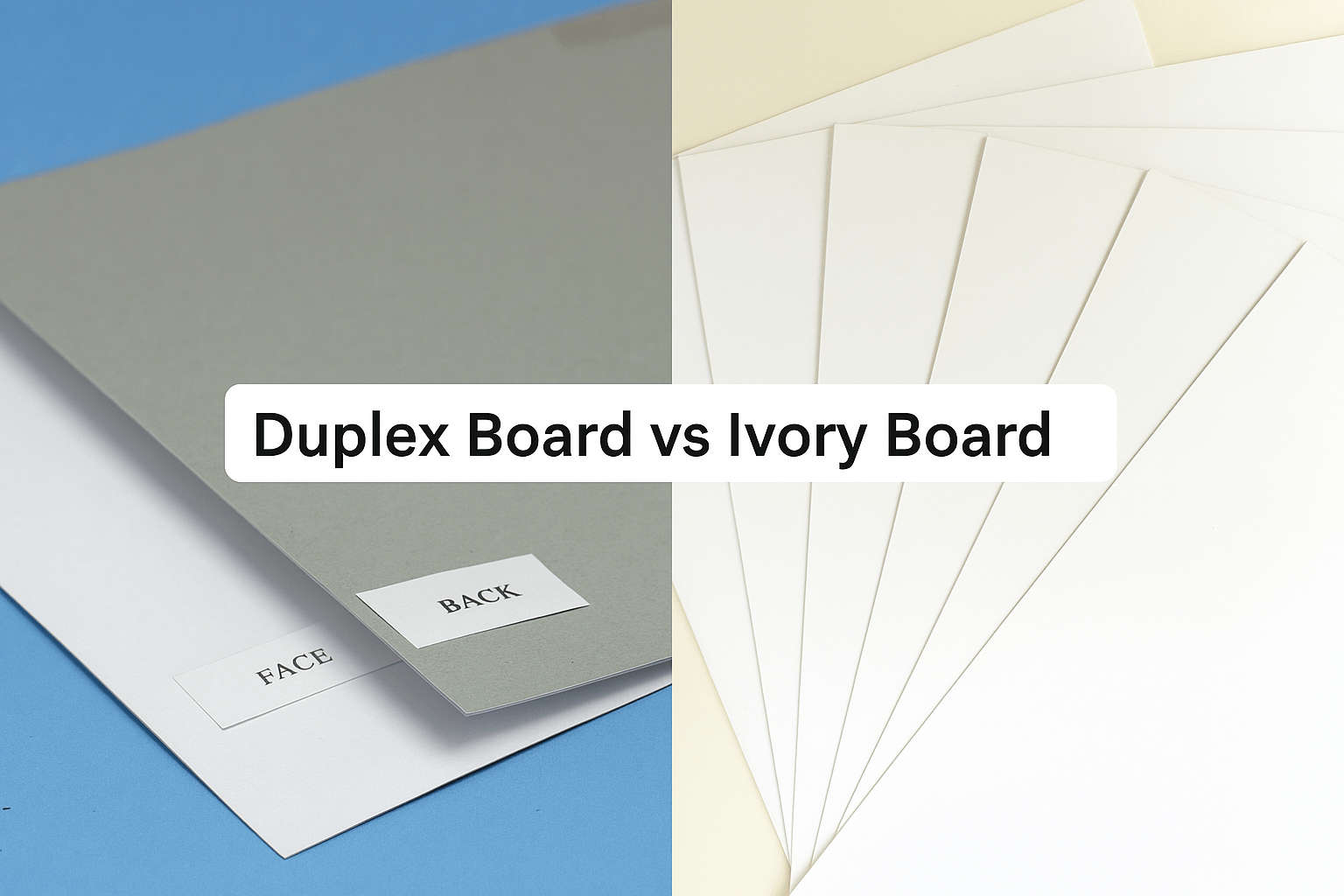

Key Differences Between Duplex Board and Ivory Board

Comparison Table Overview

Let’s start with a quick side-by-side look at how Duplex Board and Ivory Board compare across major packaging properties.

| Feature | Duplex Board | Ivory Board |

| Material Source | Mixed pulp, often recycled | 100% virgin wood pulp |

| Surface Finish | Coated on one side, uncoated back | Coated on both sides, uniform and bright |

| Durability | Moderate; suitable for standard loads | High; withstands folding and pressure |

| Printability | Good for everyday branding | Excellent for detailed and vibrant designs |

| Cost | Budget-friendly, cost-effective | Premium pricing for luxury appearance |

| Food Safety | Limited; not ideal for direct contact | Safe for food and cosmetic packaging |

| Environmental Use | Often uses recycled content | Made from virgin pulp, stricter hygiene focus |

Visual Quality and Color Reproduction

Brightness, Gloss, and Ink Absorption

Ivory board has a cleaner, brighter appearance that enhances design visibility. It reflects light well, which boosts the printed image quality. Duplex board has a duller surface that absorbs more ink, which can reduce gloss and vibrancy.

Ink absorption in duplex board is less consistent. It may cause slight bleeding or soft edges in detailed prints. Ivory board controls absorption more evenly, helping preserve sharp lines and smooth gradients. It’s especially noticeable in high-end branding or photo-based prints.

Print Sharpness and Tone Fidelity

Because of its double coating and smoother texture, ivory board handles fine tones better. When you print shadows, fades, or detailed text, it stays crisp. Duplex board does a decent job, but it can’t match the tone accuracy of ivory board in complex layouts. Color layering and rich gradients often appear more saturated and controlled on ivory board.

Structural Performance

Bending Resistance, Stiffness, Folding Endurance

Ivory board has more stiffness and rebound than duplex board. It doesn’t bend easily, so it helps packaging maintain shape longer. This is especially important for display boxes or packaging exposed to handling.

When it comes to folding, ivory board has a clear advantage. It resists cracking and keeps corners clean. Duplex board may show signs of wear or splitting if folded tightly, especially along grain lines.

Duplex board holds up well for lighter loads or single-use packaging. But ivory board works better for packaging that’s reused, reshaped, or expected to look sharp over time.

Duplex board can handle moderate pressure but softens with stress.

Ivory board is firm under pressure and maintains its flatness over time.

Repeated folds weaken duplex board more quickly than ivory board.

How to Choose Between Duplex Board and Ivory Board

Based on Budget

When to Choose Duplex Board for Cost-Effective Packaging

If your packaging needs to balance visual appeal and cost, duplex board makes sense. It’s cheaper to produce because it uses recycled pulp. That helps cut down material costs—especially for high-volume items like soap boxes or takeaway containers.

When Ivory Board Is Worth the Premium

Ivory board costs more, but you get a higher-end result. It’s best when packaging is part of the customer experience. That includes premium chocolates, high-end skincare, or personalized gifts.

Based on Industry Requirements

Cosmetics and Personal Care: Ivory board wins for its clean, smooth finish. It gives a luxurious look and holds detailed designs well.

Food Products: Duplex board is common in dry food packaging. But if the food touches the board directly, ivory is the safer choice.

Electronics and Gadgets: Duplex board offers enough structure for cables, cases, and accessories. It’s strong without being overly expensive.

Retail and FMCG: Duplex board handles fast-moving items well. For limited editions or seasonal packaging, ivory board adds an edge.

Based on Print Expectations

Design Complexity and Branding Requirements

Duplex board handles basic printing well, but struggles with complex artwork. If your packaging features bold gradients, tiny patterns, or metallic inks, ivory board is more reliable. It supports sharp lines, color contrast, and embossed designs.

Color Fidelity and Fine Details

Ivory board allows consistent color transfer. Its surface prevents ink spread, so images stay sharp. Duplex board may absorb ink unevenly, especially if the design uses subtle shading or low contrast. This matters for high-end branding where every detail counts.

Packaging Purpose

The final use of your packaging makes a huge difference. Is it for everyday sales or a special edition product?

Everyday Packaging: Duplex board is a practical, sturdy option. It suits daily-use products, mass-market items, and fast turnover inventory.

Luxury or Limited-Edition: Ivory board offers that polished feel. It holds shape, supports vibrant printing, and feels premium when handled.

Event-Based Packaging: Gift boxes, promotional kits, or holiday specials benefit from ivory board’s finish. It adds value without needing additional materials.

Technical Specifications: A Closer Look

GSM, Thickness, and Whiteness Range

Standard GSM and Thickness Comparison

Grammage (GSM) and thickness directly affect a board’s stiffness and feel. Duplex board usually ranges between 200–400 gsm and has moderate thickness. Ivory board, on the other hand, offers a tighter density, often between 230–400 gsm, with a more compact and firm build.

| Property | Duplex Board | Ivory Board |

| GSM Range | 200–400 gsm | 230–400 gsm |

| Thickness | ~0.25–0.50 mm | ~0.27–0.55 mm |

| Density Feel | Moderate | High and consistent |

Role of Whiteness in Print Quality

Ivory board is much whiter than duplex board. That matters when printing designs with bright colors or gradients. Higher whiteness reflects more light, helping the ink appear more vibrant. Duplex board’s back is usually grey or off-white, which may dull colors if printed.

Coating Materials and Effects

Duplex and ivory boards both use coating materials, but they differ in quality and purpose. Kaolin clay and calcium carbonate are common. These materials create a smoother surface, allowing ink to stay on top rather than soak in.

Kaolin Clay: Gives smoothness and improves ink hold, making images appear sharp.

Calcium Carbonate: Boosts brightness and makes coated surfaces more reflective.

Ivory board uses these coatings on both sides, making it ideal for double-sided printing. Duplex board typically coats only one side, limiting its high-end print potential.

Absorbency and Dot Gain Impact

Ink behavior depends on the paperboard’s absorbency. Duplex board has larger surface pores, which cause it to absorb ink faster. That may lead to dot gain—a blurring effect when printed dots spread beyond their intended size.

Ivory board has tighter surface texture. Ink stays on top longer, giving time for controlled drying. This reduces dot gain and helps preserve sharpness.

Global Market Demand and Usage Trends

Which Industries Use Which Board More?

The use of Duplex and Ivory boards varies across industries and regions. In the packaging sector, Duplex board is widely preferred for its strength and cost-efficiency, especially in regions like East Africa and India, where it’s used for corrugated packaging and retail boxes. Ivory board, known for its smooth surface and high-quality finish, is favored by luxury goods packaging industries globally, especially in the UAE, where it’s used for high-end retail packaging.

Regional Preferences

UAE: Ivory board dominates for luxury and high-end packaging due to its smooth finish.

India: Duplex board is commonly used for packaging solutions in retail sectors.

East Africa: Duplex board is the go-to for packaging and printing due to its durability and lower cost.

Price and Supply Factors

Both boards are available globally, but their supply can vary depending on regional demand. Duplex board, being less costly, is readily available in most markets, especially in regions with high-volume manufacturing needs. On the other hand, Ivory board can be harder to source due to its premium nature and the specific production techniques it requires.

Availability in Global Markets

Duplex board: Widely available, with supply chains in Asia, the Middle East, and Africa.

Ivory board: More localized, often imported to markets with a higher demand for premium packaging.

Sizing and Custom Requirements

Both boards are available in various sizes, though custom sizes can significantly affect the price. Duplex board is often sold in larger quantities for mass production, while Ivory board is available in specific sizes for high-end packaging and custom orders.

Conclusion

Selecting the right paperboard is essential for effective packaging. Duplex Board offers affordability and strength, ideal for food and electronics packaging. Ivory Board, known for its smooth finish, suits luxury items like cosmetics. Consider your packaging needs and budget for the best choice.

Evaluate your specific requirements, including print quality and durability, to decide whether Duplex or Ivory Board is right for your project. Both options cater to different needs, so choosing the right one ensures your packaging stands out and meets product demands.

FAQs

What is the main difference between Duplex Board and Ivory Board?

The main difference lies in their finish. Duplex board is made with a white surface on one side and gray on the other, making it ideal for packaging. Ivory board, however, has a smooth, premium finish on both sides, often used for high-end packaging like cosmetics or luxury goods.

Can Duplex Board be used for food packaging?

Yes, Duplex board is often used for food packaging, especially for products like take-out containers, since it’s durable and cost-effective. However, for food safety, ensure it’s properly coated for moisture protection.

Is Ivory Board more durable than Duplex Board?

Not necessarily. While Ivory board has a smoother finish, it is not always more durable. Duplex board, with its thicker structure, can offer better strength, especially for heavy-duty packaging.

What is the best paperboard for cosmetic packaging?

Ivory board is the best option for cosmetic packaging due to its smooth surface, which offers high-quality print results. Its premium look and feel are perfect for luxury product presentations.