Kraft paper is everywhere—yet many people don’t realize how versatile and essential it truly is. From strong packaging to creative projects, the uses of kraft paper go far beyond wrapping boxes.

In this post, you’ll learn what kraft paper is, what makes it so durable and cost-effective, and how it's used across industries like packaging, food, construction, and more. We’ll also explore different types of kraft paper and how to choose the right one for your needs.

What Is Kraft Paper?

Kraft paper is a strong, flexible paper that’s widely used for wrapping and packaging. But what exactly makes it different from regular paper? Let’s break it down.

What Does "Kraft" Mean?

The word “kraft” comes from the German word for “strength.” And it’s not just a name—it describes what the paper is built for. Kraft paper is made to handle pressure, weight, and rough handling. That’s why you see it in places like grocery bags, shipping wraps, and even industrial covers.

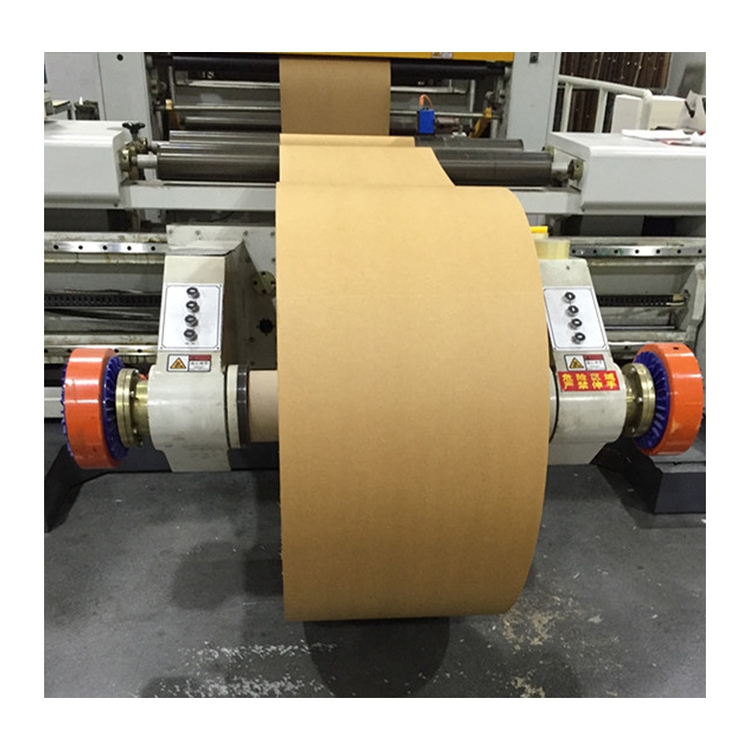

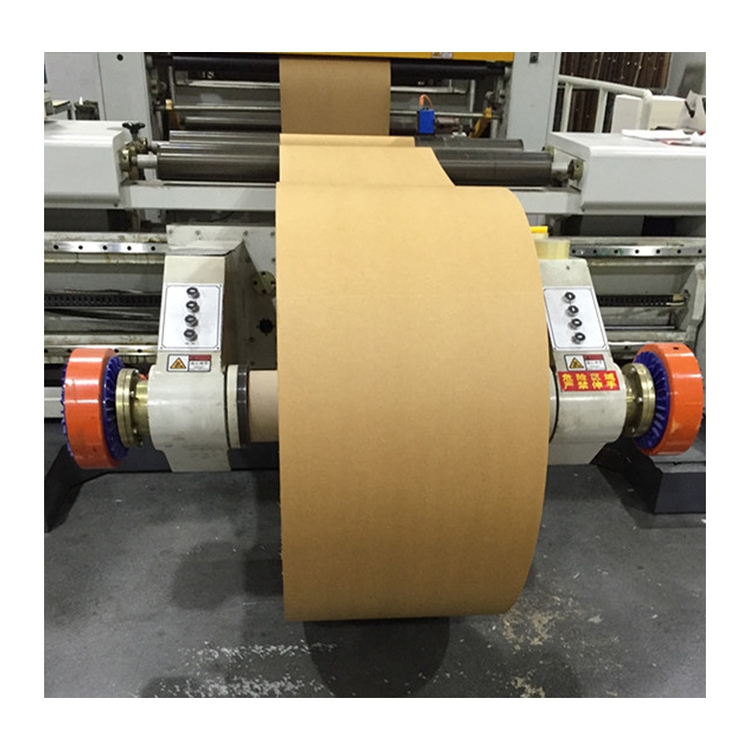

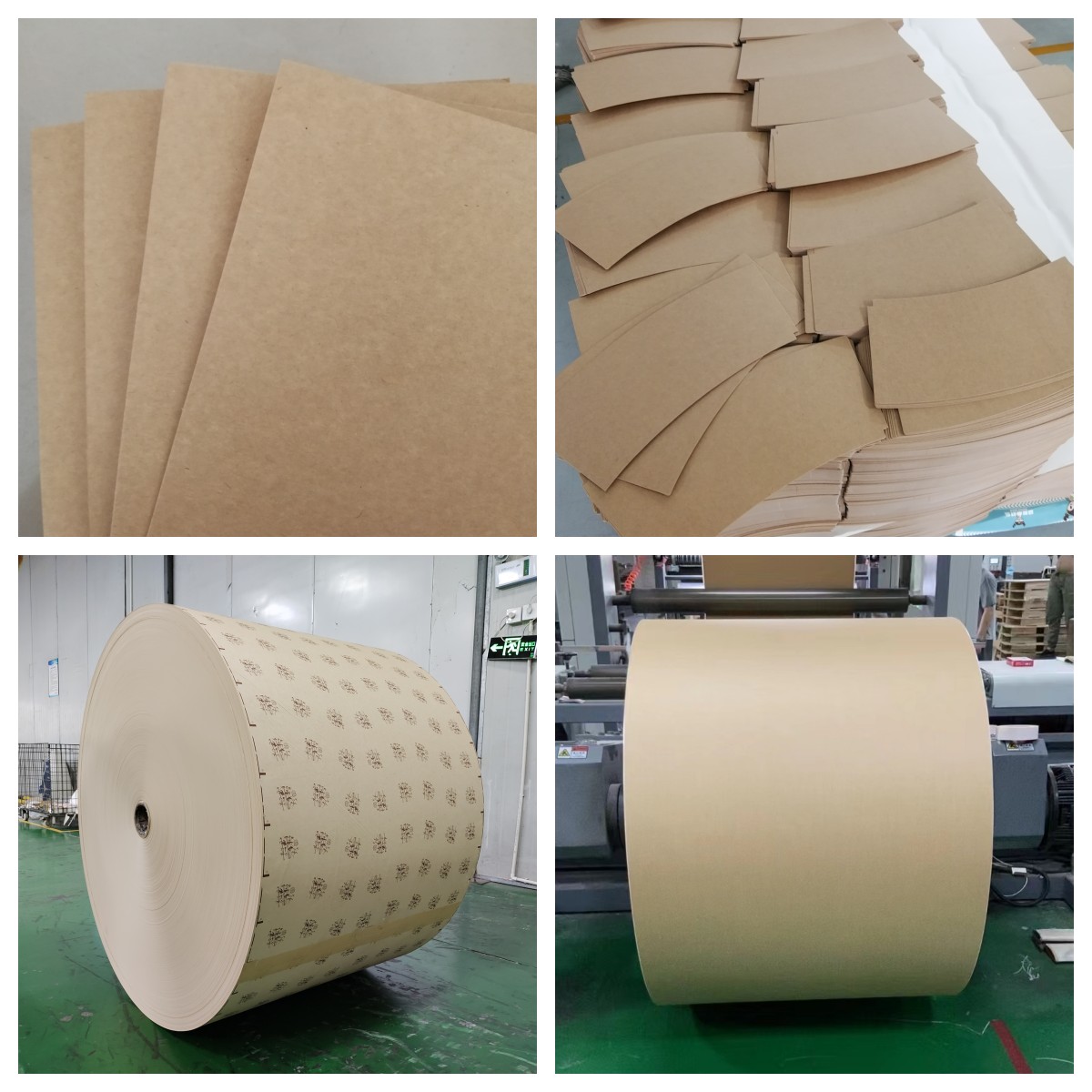

How Is Kraft Paper Made?

The process used to make kraft paper is called the kraft pulping process, which removes a lot of the natural materials—like lignin—from wood. What’s left behind? Mostly cellulose fibers. These fibers are long and strong, perfect for making durable paper. Unlike some paper-making methods, this process keeps the fibers tough, giving kraft paper its high tear resistance.

Here’s a quick breakdown of the kraft process:

| Step | Description |

| 1. Wood Collection | Usually softwood or a mix of wood types. |

| 2. Pulping | Wood chips are cooked with sodium hydroxide and sodium sulfide. |

| 3. Washing & Screening | Removes unwanted particles and lignin. |

| 4. Drying | The pulp is dried into large rolls of brown kraft paper. |

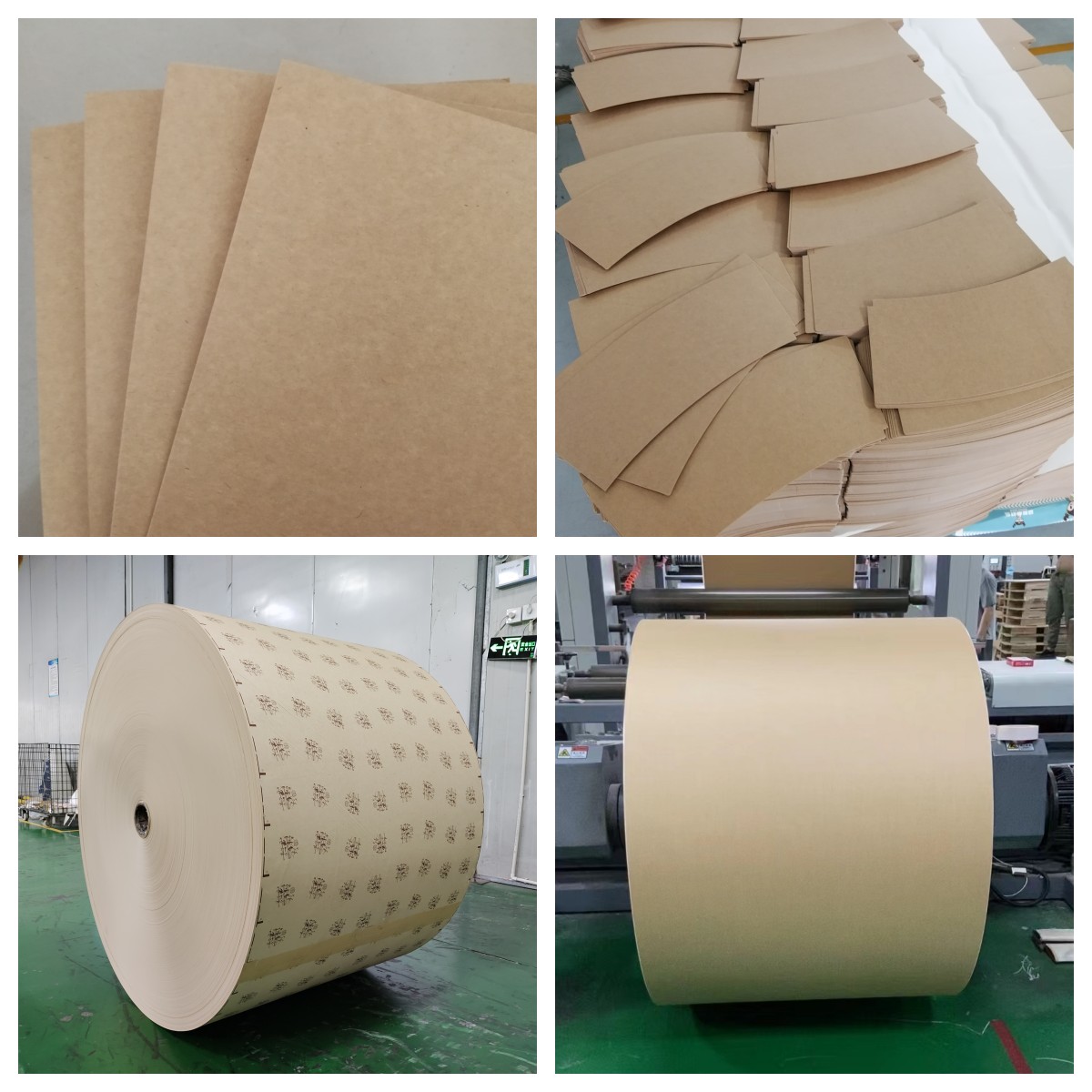

What Does Kraft Paper Look and Feel Like?

Color: Most often brown, but it can also be bleached to make it lighter or white.

Texture: A bit rough and fibrous to the touch, not smooth like printer paper.

Tear Resistance: It doesn’t tear easily. This is one of the reasons it’s used for packing and shipping.

Weight Options: Comes in different thicknesses (GSM), so you can find light or heavy-duty versions.

Why Choose Kraft Paper Over Other Types?

It’s stronger than bond or printing paper, especially for heavy loads.

It handles wear and friction better than carbonless or thermal paper, which are designed for specific printing jobs.

It's flexible—used in art, packaging, and even food wrapping.

Common Types of Kraft Paper

Virgin Kraft Paper

Virgin kraft paper is made from unprocessed wood pulp and is known for its high strength and durability. The fibers in this paper are longer and stronger, making it ideal for heavy-duty applications. It’s often used for things like industrial bags, protective packaging, and carrier sheets where high tear resistance is essential. Because it hasn’t been recycled, its structure holds up better under pressure and friction.

Recycled Kraft Paper

Made from post-consumer and post-industrial waste, recycled kraft paper is a more economical option that still performs well for many tasks. It’s softer and slightly less durable than virgin kraft, but it’s perfectly suitable for light to medium uses like wrapping, inner packaging, and craft projects. Many businesses use it to fill boxes, wrap fragile items, or for layering between goods during transport. It balances cost with functionality.

| Feature | Virgin Kraft | Recycled Kraft |

| Fiber Source | Fresh wood pulp | Recycled paper |

| Strength Level | Very strong | Moderate |

| Best Use Case | Heavy loads | Everyday wrapping |

| Surface Texture | Slightly rough | Slightly softer |

Bleached Kraft Paper

Unlike the brown shade we usually associate with kraft, bleached kraft paper is processed to remove its natural color. This gives it a clean, white appearance that’s better suited for branding and print work. It’s frequently used for food liners, custom shopping bags, envelopes, and packaging where aesthetics matter more. The surface is smoother, which helps when applying logos, inks, or printed designs.

Coated Kraft Paper

Coated kraft paper has an added layer—usually polyethylene or a similar barrier—that makes it resistant to moisture and grease. This type of kraft paper is especially useful in food service, industrial settings, and any situation where the paper needs to stay dry or clean. It feels smoother than uncoated kraft and often has a slightly shiny finish. Depending on the type of coating, it can also block light, heat, or odors.

Coating Materials and Benefits

| Coating Type | Purpose | Common Use |

| PE Coating | Blocks moisture and oil | Food wraps, cold storage bags |

| Wax Coating | Adds flexibility and shine | Bakery sheets, butcher paper |

| Aluminum | Reflects heat and light | Insulated packaging |

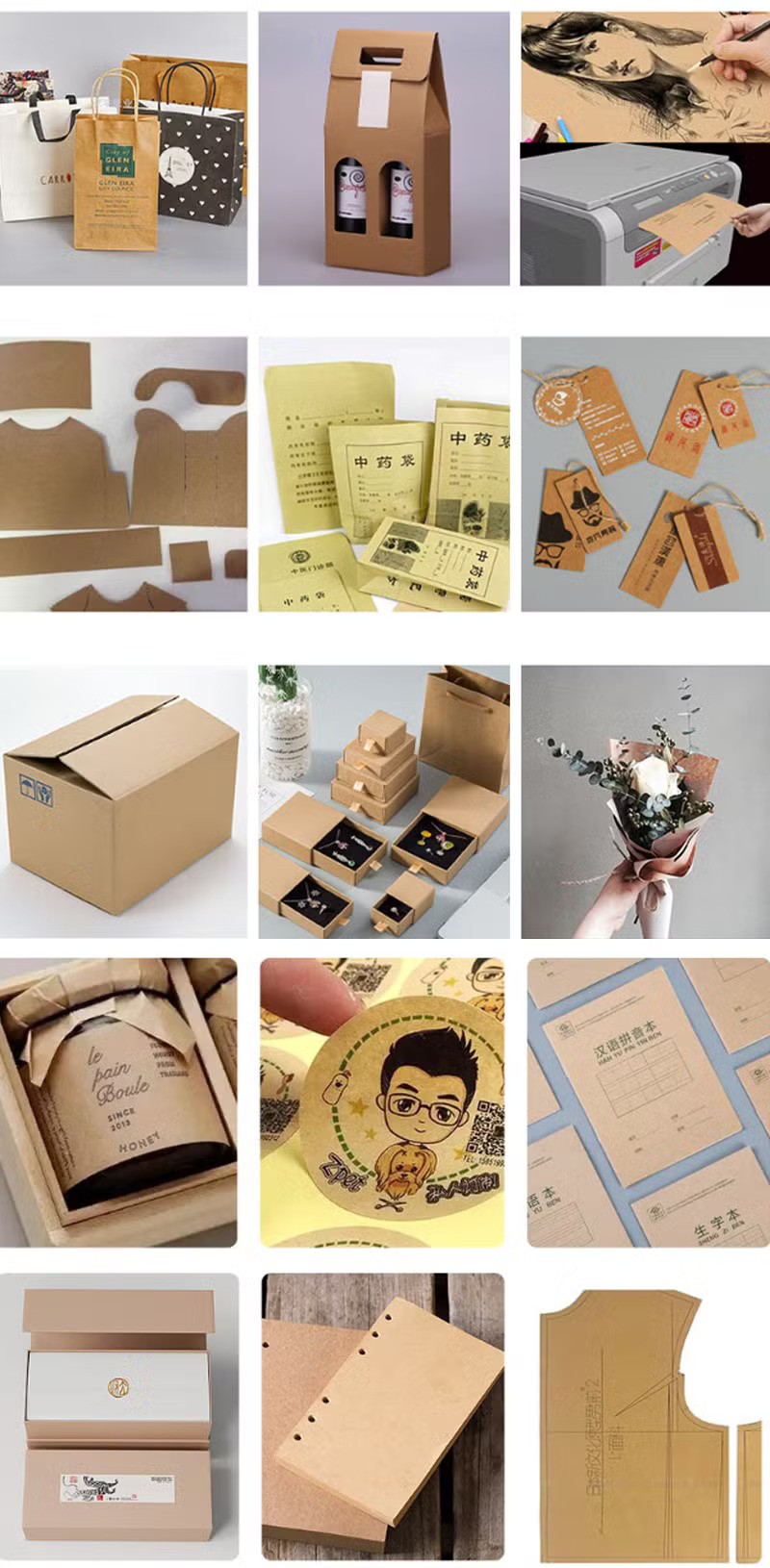

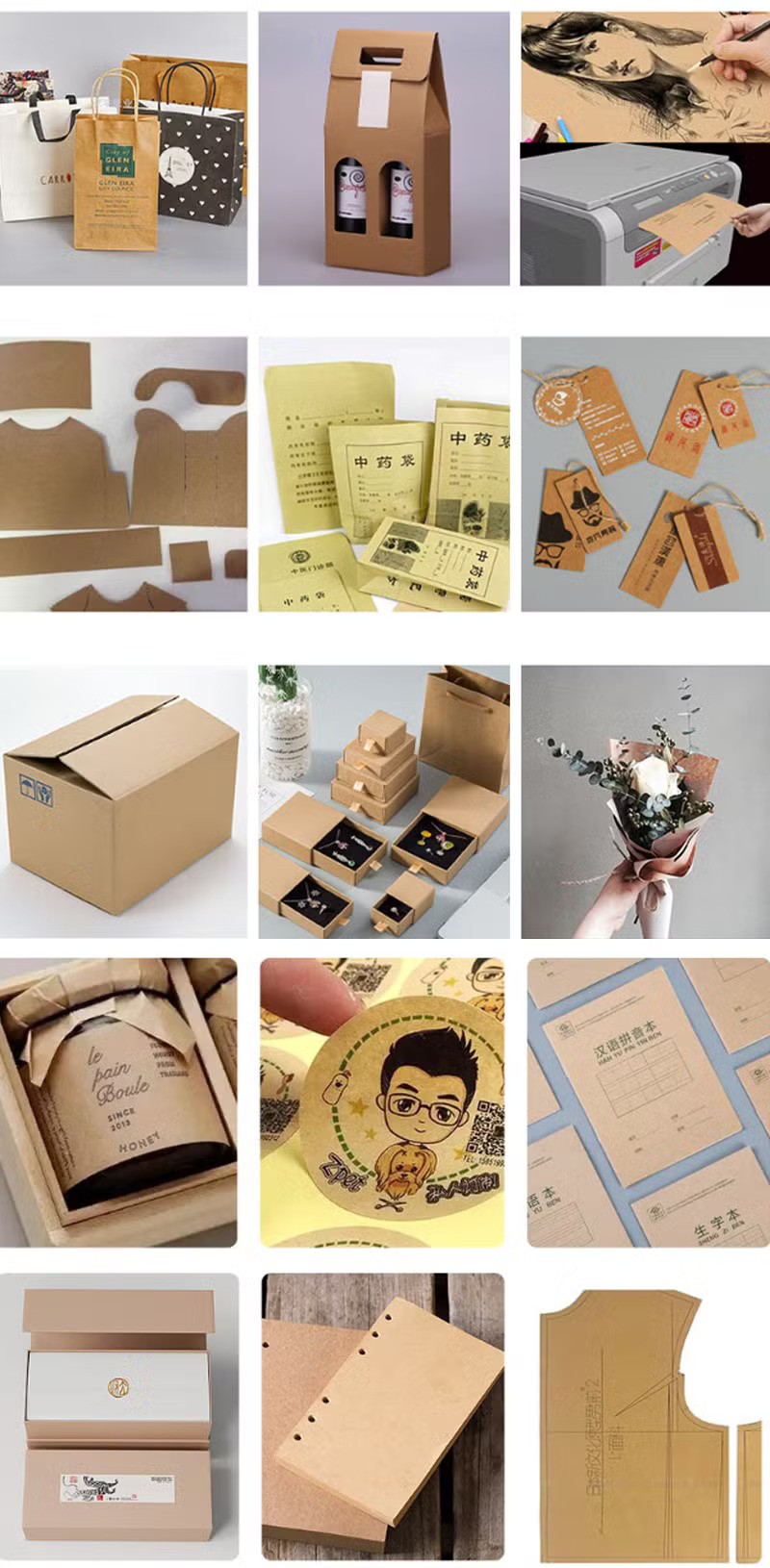

Main Uses of Kraft Paper

1. Packaging and Wrapping

It’s hard to beat kraft paper when it comes to basic wrapping needs. People often use it to wrap packages, fragile items, or industrial tools before shipping.

It helps cushion breakables and fills space inside boxes to reduce movement.

Compared to bond paper, kraft paper is stronger, rougher, and handles stress better.

Its stretch resistance makes it perfect for bundling oddly shaped or heavy items.

| Paper Type | Strength | Texture | Best Use |

| Kraft Paper | High | Coarse | Shipping, protection |

| Bond Paper | Low | Smooth | Office use, documents |

2. Kraft Paper Bags

Brown paper bags aren’t just for groceries—they’re everywhere. Stores, cafés, and markets rely on them daily.

They’re stronger than typical plastic alternatives and hold up well under weight.

Shoppers use them for food, books, clothes, or any quick carry-around items.

Some bags also have twisted handles or reinforced bottoms, making them more durable for repeated use.

3. Envelopes and Mailing

Mailing supplies like kraft envelopes are built to last through rough handling.

They're often used to ship documents, books, or compact goods.

Their thick, tear-resistant material helps keep items intact in transit.

These envelopes come in various sizes, and many include peel-and-seal strips or metal clasps.

4. Printing and Branding Applications

Kraft paper gives off a natural, minimalist look that's great for branding.

It works well for hang tags, printed boxes, thank-you cards, and stickers.

Inkjet, screen printing, and even stamping techniques show up nicely on its surface.

Brands that want a rustic, handmade, or vintage feel often pick kraft for their packaging.

5. Construction and Surface Protection

Before painting or remodeling, people often use kraft paper to protect floors or surfaces.

It’s laid out over hardwood, tiles, or countertops to guard against drips and dust.

Painters also cut it into strips for masking trims, edges, and hardware.

Rolls are available in multiple thicknesses depending on the level of protection needed.

6. Food Packaging

Not all kraft paper is food-safe, but certain types are specially treated for contact with food.

Common uses include sandwich wraps, tray liners, and pastry sheets.

White kraft—also known as bleached kraft—is often chosen for bakery items.

To avoid safety issues, it’s best to confirm that the kraft paper meets food-grade standards before use.

| Kraft Type | Food Use | Notes |

| Bleached Kraft | Bakery, snacks | Clean look, good print quality |

| Unbleached Kraft | Casual wraps | Natural feel, not always food-safe |

7. Arts, Crafts, and DIY

Crafters love kraft paper for its versatility and earthy tone.

It works great for making handmade cards, posters, or scrapbook pages.

Kids use it for school projects like drawing or paper models.

Kraft Paper vs Other Paper Types

Kraft Paper vs Bond Paper

Strength and Durability

Kraft paper is much tougher than bond paper. It’s built from longer fibers, which makes it harder to tear or crumple. Bond paper, though smoother, is more fragile. If you fold it too often, it starts to weaken or break.

Color and Surface

Bond paper usually comes in white or light colors, with a smooth surface made for pens and printers. Kraft, on the other hand, keeps its natural brown tone. It’s rougher, not ideal for detailed printing or crisp text.

Use Case Comparison

Kraft paper is used for wrapping, bags, and crafts. It holds up under weight and stress.

Bond paper fits offices and schools—meant for clean text, copying, and inkjet printers.

| Feature | Kraft Paper | Bond Paper |

| Color | Brown / Off-white | Bright white / Pastels |

| Surface Texture | Coarse | Smooth |

| Durability | High | Low to Medium |

| Typical Uses | Packaging, crafts | Printing, writing |

| Folding Resistance | Strong | Weaker |

Kraft Paper vs Thermal and Carbonless Paper

Why Kraft Isn’t Used for Receipts

Kraft doesn’t work in receipt machines. It can’t react to heat or pressure. Thermal printers need special coatings—kraft has none. Carbonless paper relies on layers and dye capsules. Kraft just absorbs ink; nothing more.

Differences in Printing Mechanisms

Thermal paper prints using heat—no ink needed. The coating darkens when heated.

Carbonless paper has chemical layers. Writing on top creates marks on copies below.

Kraft paper uses traditional ink printing. No heat reaction, no layered dye system.

| Printing Type | Thermal Paper | Carbonless Paper | Kraft Paper |

| Heat Sensitive | √ | × | × |

| Pressure Sensitive | × | √ | × |

| Requires Ink | × | √ (partial) | √ |

| Used for Receipts | √ | √ | × |

Where Each Fits

You’ll find kraft in packaging, not next to a receipt printer. It’s not meant for fast, automated printing. Thermal paper handles single-copy receipts fast. Carbonless suits delivery slips or forms that need duplicates. Kraft stays in its lane—strong, but not smart-print friendly.

Factors to Consider When Choosing Kraft Paper

GSM (Grams per Square Meter)

Lower GSM for Wrapping and Crafts

Kraft paper with a lower GSM is lighter and more flexible, making it perfect for wrapping gifts or creating paper crafts. It bends easily and doesn't add much bulk, making it ideal for decorative purposes or light-duty tasks.

Higher GSM for Packaging, Industrial Use

For packaging and industrial applications, higher GSM kraft paper is necessary. The thicker paper provides extra strength, ensuring it can withstand weight, pressure, and rough handling. It’s often used for shipping boxes and heavy-duty bags.

Color and Coating Needs

Brown vs Bleached (Appearance and Branding)

Kraft paper typically comes in a natural brown color, giving it an organic, rustic feel. This works well for branding that emphasizes eco-friendliness. Bleached kraft offers a cleaner, brighter appearance, ideal for a more polished look or when color printing is involved.

Coated vs Uncoated (Moisture Resistance and Handling)

Coated kraft paper has a thin layer that makes it more resistant to moisture, which is useful in environments where the paper may be exposed to humidity or liquids. Uncoated kraft, while less resistant to moisture, offers better printability and a more textured surface, making it great for artistic uses.

Intended Application

Matching Kraft Paper Features to Specific Use Cases

When choosing kraft paper, it’s important to match its features to your needs. For lightweight applications like gift wrapping, go for low GSM, uncoated brown kraft. If you need kraft paper for industrial purposes like shipping, a higher GSM with a coated finish would work better. Consider the strength and appearance based on whether it's for functional packaging or branding.

Advantages of Kraft Paper

High Tensile Strength and Tear Resistance

Kraft paper is known for its impressive strength. Made from long fibers, it’s tough and resistant to tearing. Whether for wrapping or heavy-duty packaging, it holds up well under stress, making it perfect for items requiring extra durability.

Affordable and Widely Available

Kraft paper is cost-effective and easy to find in most markets. It’s one of the most budget-friendly options available, whether for small craft projects or large-scale packaging needs. Its widespread availability makes it accessible for most businesses and consumers.

Printable and Adaptable to Various Formats

The surface of kraft paper can handle ink printing well, making it ideal for branding, logos, and other designs. It works for both hand-written and machine printing. Additionally, it can be shaped into various formats, such as rolls or sheets, to suit different industries' needs.

Limitations of Kraft Paper

Not Naturally Moisture-Resistant (Unless Coated)

Kraft paper absorbs moisture easily and can weaken when exposed to water. Without a coating, it is not suitable for applications where moisture resistance is essential, like in wet environments or outdoor storage.

Coarse Surface Limits Certain Types of High-Resolution Printing

The rough texture of kraft paper can make it challenging for high-resolution printing. Fine details or sharp images may not print as clearly, making it less ideal for projects requiring intricate designs or photographic quality.

May Not Be Suitable for All Food-Grade Needs

Kraft paper may not be appropriate for certain food-grade packaging. Without a coating, it can absorb oils and moisture from food, potentially compromising its quality and hygiene in food packaging, especially for greasy items.

Conclusion

Kraft paper stands out for its strength, flexibility, and wide range of applications—from packaging and mailing to crafts and food wraps. Whether it's virgin, recycled, or coated, each type offers specific benefits that fit different needs. Its adaptability makes it a go-to solution across industries and daily use.

If you're choosing paper for business or creative projects, kraft is a smart, reliable option. Think about GSM, surface texture, and your application needs. Don’t settle for generic paper—match the kraft type to your goals for better results and smoother processes.

Frequently Asked Questions (FAQ)

Is kraft paper recyclable?

Yes, kraft paper is recyclable. Since it’s made from wood pulp, it can be recycled and used for various products.

Can you print on kraft paper?

Yes, you can print on kraft paper. It holds ink well, making it suitable for logos, text, and designs.

Is kraft paper waterproof?

Kraft paper is not naturally waterproof. However, when coated, it becomes resistant to moisture and suitable for specific applications.

What GSM should I choose for packaging?

For packaging, choose a higher GSM (about 200-400). This provides the strength needed for heavier items and protects them well.

Reference Sources

[1] https://www.uniuso.com/blog/en/what-is-kraft-paper-and-what-is-it-used-for/

[2] https://shreevarudi.com/blog-details/types-of-kraft-papers-its-uses

[3] https://www.transpack.co.uk/blog/top-5-kraft-paper-uses/

[4] https://www.enpaktw.com/blog/22-kraft-paper-the-sustainable-choice-for-food-packaging

[5] https://pakfactory.com/blog/what-is-kraft-paper/

[6] https://en.wikipedia.org/wiki/Kraft_paper

[7] https://www.rppaperimpex.com/uses-of-kraft-paper/

[8] https://info.primepac.co.nz/blog/types-of-kraft-paper-and-their-uses

[9] https://inviker.com/en/blog/products-packaging/kraft-paper-uses-and-sustainable-benefits/