Ever wondered why Kraft paper is everywhere—from grocery bags to fancy gift wraps? This strong, natural-looking material is more than just brown paper; it's a packaging powerhouse used across food, retail, and industrial settings.

In this post, you’ll learn about the different types of Kraft paper, how they’re made, their unique features, and which type fits your specific needs. Whether you're choosing between virgin vs. recycled Kraft or exploring coated and specialty varieties, this guide breaks it all down in a simple, easy-to-understand way.

What is Kraft Paper?

Definition and Key Traits

Kraft paper is a durable, rough-textured material made from wood pulp. It’s usually brown, sometimes white, and has a natural, no-fuss look. It’s known for being tough and flexible — great for packaging and wrapping.

Main characteristics:

Strong and tear-resistant

It holds up under stress, making it perfect for heavy loads and rough handling.

Natural texture

Its coarse surface isn’t smooth or shiny. That’s part of its charm — easy to grip and write on.

Durability and flexibility

It bends, folds, or crumples without falling apart.

| Property | Description |

| Color | Typically brown; can be bleached white |

| Strength | High tear and burst resistance |

| Texture | Rough, fibrous surface |

| Common Uses | Bags, boxes, wraps, craft, envelopes |

How It's Made

Kraft paper isn’t made like standard paper. It’s produced using a chemical method that gives it extra strength.

The Kraft Process

Wood chips are cooked in a mixture of sodium hydroxide and sodium sulfide. This breaks down lignin — the glue-like stuff that holds wood fibers together — and leaves behind strong cellulose fibers.

Virgin Pulp vs Recycled Fiber

Two main sources of fiber go into kraft paper:

Virgin pulp

Comes straight from wood. Long, clean fibers make the paper stronger and more reliable.

Recycled fiber

Made from used paper. It's cheaper and greener, but fibers may be shorter and weaker.

Most kraft papers blend both types to balance quality and cost.

Bleaching and Coating Options

Some kraft paper gets extra treatment:

Bleaching

Strips the brown color, turning the paper white. Often used when printing or branding is needed.

Coatings

Layers like wax or polyethylene (PE) make it water-resistant. These coatings are common in food packaging or industrial wrap.

Applications of Kraft Paper

Packaging and Shipping

Kraft paper is widely used to wrap boxes, pad interiors, and fill voids in packaging. It’s strong, flexible, and holds up well in transit. Sack kraft is used for heavy-duty bags that carry grains, cement, or chemicals without tearing or leaking.

Food Industry Use

Grease-resistant kraft wraps keep burgers and fried foods neat without soaking through.

Lined kraft containers hold hot or saucy items like noodles or pasta.

Dry foods such as flour or rice are often packed in uncoated kraft bags for safe storage.

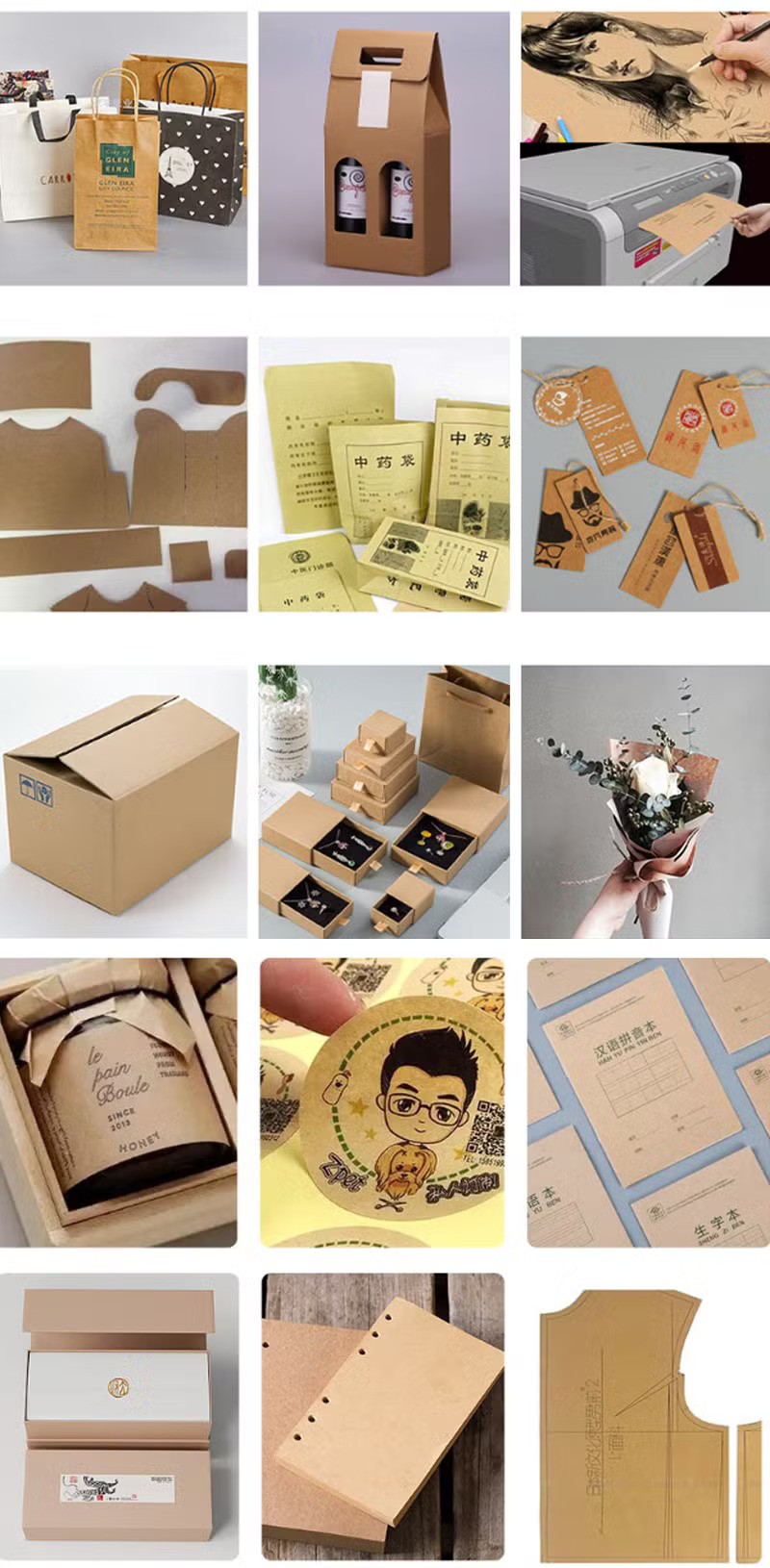

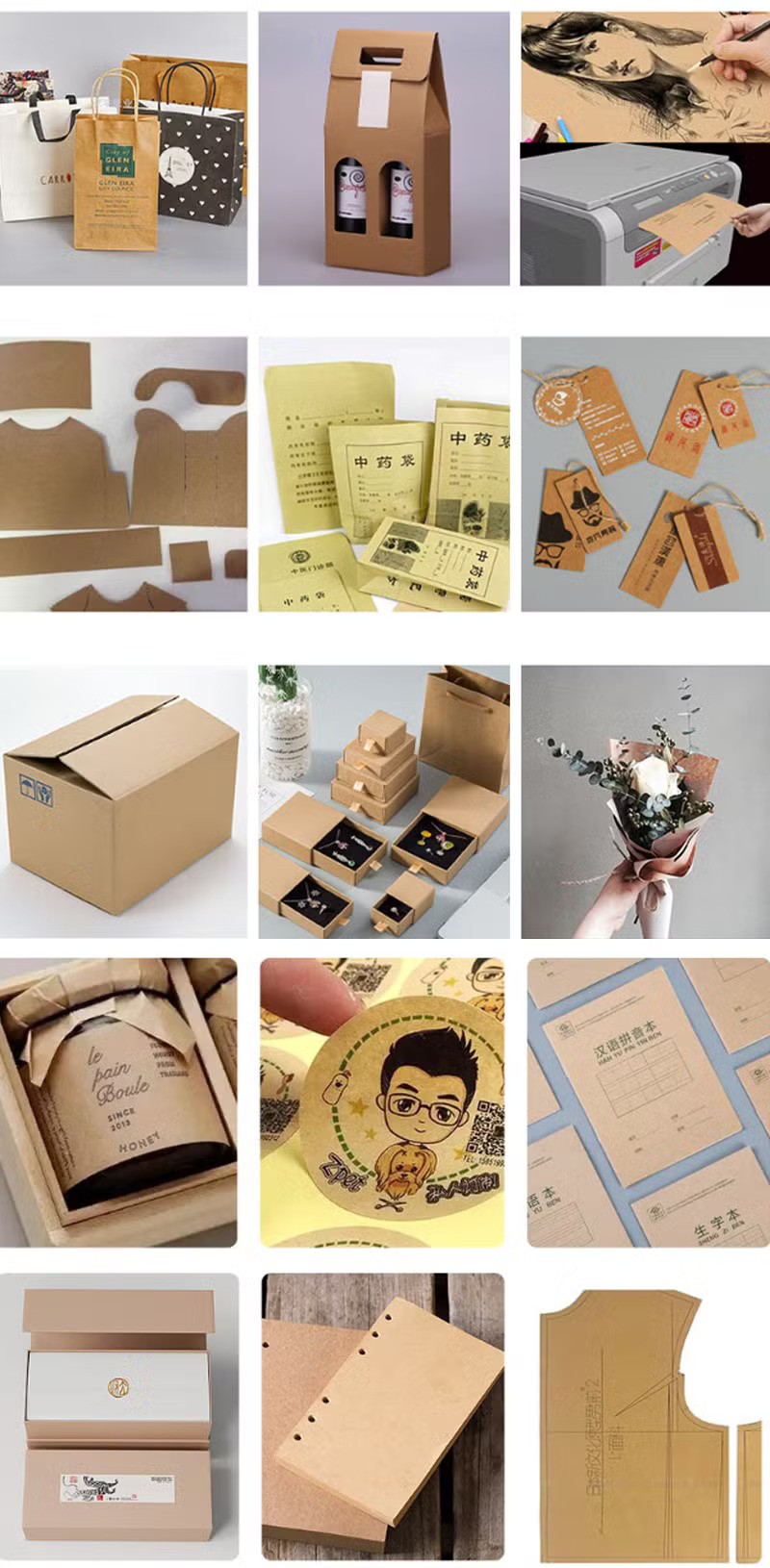

Arts, Crafts, and Retail

Kraft paper gives a handmade look in retail and crafts. It’s used for wrapping gifts, making stationery, or printing hang tags. Small businesses often prefer it for packaging that looks warm and personal yet remains affordable.

Construction and Industrial Use

Rolls of kraft are laid on floors during renovation to catch paint, dust, or debris.

Used as insulation backing, it adds support and holds shape for stapling or layering.

Factories wrap machinery in kraft to block out dust, prevent scratches, or light moisture exposure.

Types of Kraft Paper

Kraft paper comes in more than one style. Each type offers a different texture, finish, and use. Whether you’re wrapping a sandwich or building a shipping box, there’s a version for it. Below, we’ll break down the most widely used types of kraft paper and what makes each one different.

Virgin Kraft Paper

What it is:

Made from 100% pure wood pulp, virgin kraft is the strongest and cleanest form. It doesn’t contain any recycled fibers, which keeps its performance high in industrial and food-related uses.

✅ Key Features:

Extremely strong and tear-resistant; can hold weight and pressure without ripping easily.

Consistent surface makes it easy to print logos, labels, and fine details without smudging.

Commonly used where appearance and hygiene matter, like in premium food wrap and retail boxes.

Recycled Kraft Paper

What it is:

This kraft is made from reused materials like old paper bags and packaging. It’s more eco-aware in production, though a bit less sturdy than virgin kraft.

✅ Key Features:

Works best for lightweight products or filler material that doesn’t require a lot of support.

More affordable than virgin kraft, which helps businesses cut costs on bulk packaging.

Texture can vary slightly due to fiber mix, but still takes ink and folds well.

White Kraft Paper

What it is:

White kraft is chemically bleached to remove the natural brown color. This gives it a cleaner, brighter surface.

✅ Key Features:

Often used in bakeries or clinics where a clean, professional look is needed.

Easier to print with colored ink and patterns, so it’s often used for branding.

Has the same basic strength as brown kraft, though some versions are thinner.

Black Kraft Paper

What it is:

Unlike painted surfaces, this paper is dyed completely black through the fiber. The dark color gives off a bold, elegant appearance.

✅ Key Features:

Popular with gift wrap, especially when paired with metallic ink or foiled logos.

Often found in menus, jewelry packaging, or labels where contrast is important.

Adds a premium feel to simple items, even with minimal design elements.

Coated Kraft Paper

Coatings give kraft paper new abilities. Here's a quick look at each type:

| Coating Type | Common Use | Advantage |

| PE-coated | Frozen foods, greasy meals | Blocks moisture and oil |

| Wax-coated | Bakery and deli wraps | Flexible and greaseproof |

| Laminated | Sealed snack bags, coffee pouches | Adds strength, seals air and scent |

These coatings make kraft paper useful in food packaging and other leak-prone tasks.

Sack Kraft Paper

What it is:

This kraft is engineered for heavy-duty tasks. It’s thick, flexible, and highly resistant to punctures or tearing.

✅ Key Features:

Often layered for better durability in packaging items like cement, feed, and dry food.

Special construction allows it to hold shape even under rough handling.

Can support bulk weight without failing, making it ideal for large-scale packaging.

Machine Glazed (MG) Kraft Paper

What it is:

Glossy on one side, matte on the other. The shiny side is smoothed using a drying cylinder, known as the Yankee dryer.

✅ Key Features:

Great for colorful printing like wrapping paper, gift bags, or specialty sleeves.

Reflective side gives packaging a higher-end look with only minor design effort.

Stiffer than most paper wraps, so it holds creases and shapes nicely.

Machine Finished (MF) Kraft Paper

What it is:

This type has an even texture on both sides, giving it a balanced finish. It doesn’t shine, but it’s easy to handle.

✅ Key Features:

Commonly used in printing, folding cartons, and envelope production.

Smooth surface holds ink well and reduces smudging during fast printing jobs.

Slightly softer feel than MG kraft, which makes folding easier and cleaner.

Corrugated Kraft Paper

What it is:

This paper forms the inside or outer layer of corrugated board. A fluted layer sits between flat kraft sheets.

✅ Key Features:

Used in shipping boxes because it adds strength without adding much weight.

Provides structure that resists crushing, bending, and shock during transit.

Comes in several flute types (A, B, C, E), each with different cushioning strength.

Specialty Kraft Paper Types

These niche types serve special purposes where standard kraft won’t work:

Greaseproof Kraft:

Treated to resist oil and grease, it’s found in burger wraps, pastry liners, and fast food trays.

Fire Retardant Kraft:

Used in buildings and events, this kraft is made to slow flame spread and meet safety codes.

Crepe Kraft:

Stretchy with a crinkled surface. It’s great for odd-shaped items like wine bottles or rolled textiles.

Colored Kraft:

Available in bold, flat colors that reduce the need for printing. Often used in craft kits or children’s packaging.

Comparison Table: Common Kraft Paper Types

| Type | Appearance | Strength | Best Use Case | Coated Option |

| Virgin Kraft | Brown, unbleached | Very High | Food, industrial packaging | Optional |

| Recycled Kraft | Brown, rougher | Moderate | Inner wraps, eco uses | Optional |

| Bleached Kraft | White, smooth | High | Retail, food, cosmetics | Optional |

| Sack Kraft | Brown, heavy-duty | Very High | Bulk product bags | No |

| Coated Kraft | Glossy/matte | Varies | Food-safe, moisture-resistant | Yes |

| MG/MF Kraft | Glossy or smooth | Medium | Printing, branding | No |

How to Choose the Right Kraft Paper

Application-Specific Factors

Start by thinking about the material’s function. Is it wrapping food, lining boxes, or carrying weight?

For anything in contact with food, choose food-safe options like wax-coated or PE-coated kraft. These block moisture and grease effectively.

If durability is key—like packaging heavy goods—use sack kraft or corrugated kraft. They resist tearing and hold shape well.

In humid or refrigerated environments, coated versions provide better barrier protection than plain kraft.

Print and Branding Needs

Uncoated kraft soaks up ink, which can dull fine print and soften colors. Good for simple, rustic branding.

Glossy or machine-glazed kraft holds ink on the surface, giving brighter prints and sharper details.

White kraft is best for full-color designs. Brown or black kraft works well for bold or minimal visuals, but may affect color accuracy.

Weight and Format Selection

Sheets are neat and ready for die-cutting or printing. Rolls are more flexible—ideal for continuous-use stations or manual wrapping.

Lighter kraft (around 40–80 GSM) suits interleaving, filler, and fast wrapping.

Heavier grades (100–200+ GSM) work better for structural items like shopping bags, boxes, or protective liners.

Kraft Paper vs Other Packaging Materials

Kraft paper often gets compared to materials like folding boxboard, SBS board, and cardstock. Each has different strengths, textures, and uses depending on packaging needs.

Kraft Paper vs Folding Boxboard (FBB)

Kraft paper is stronger and more tear-resistant, which makes it better for handling heavy or oddly shaped items. It’s also more textured, giving packaging a raw, natural feel that works well for brands going for a rustic or handmade vibe.

Folding boxboard (FBB) is much smoother and more rigid. It prints cleaner, folds sharply, and is often used in cosmetics, pharmaceuticals, or premium retail packaging where neatness and visual detail are more important than durability.

Kraft Paper vs SBS Board

Kraft has a fibrous surface and usually comes in brown or dyed variants like black. While you can coat it for better printing, it still won’t produce colors as cleanly or brightly as pure white materials. It’s great for simple, bold designs or earthy aesthetics.

SBS board (Solid Bleached Sulfate) is white from the core to the surface. This uniform color helps full-color prints look sharp and professional. It’s commonly used for luxury packaging or products that need precise branding, like electronics, cosmetics, or upscale food.

Kraft Paper vs Cardstock

Kraft paper is softer and more flexible than cardstock. It bends easily, resists tearing, and adds a handmade, organic touch to packaging or tags. It’s ideal for wrapping, folding, or designs where texture plays a role in the overall look.

Cardstock feels stiffer and holds shape better. That makes it great for flat applications like postcards, greeting cards, or signage. It has less give and may crack at folds if not pre-scored, but offers a smoother base for detailed printing and specialty finishes.

Printing and Converting Kraft Paper

Printing Compatibility

Kraft paper supports several printing methods, including offset, flexo, and screen printing. Brown kraft absorbs more ink, so bold designs work best. Fine lines or light colors may lose clarity. White kraft offers a smoother surface and better color accuracy—ideal for detailed graphics or gradients.

Die-Cutting and Finishing

Kraft paper handles die-cutting, creasing, and embossing well, especially at higher GSMs. It resists cracking along folds and holds shape cleanly. Smoother kraft grades are better for foil stamping, while rougher ones may need extra pressure or heat adjustments to get crisp results.

Storage and Handling Tips

Keep in dry, cool areas

Store kraft paper in a cool, dry place to avoid weakening. Ideal conditions are between 50°F and 70°F (10°C to 21°C), with low humidity.

Prevent curling or creasing during handling

Always store paper flat to prevent curling or creasing. When moving, use protective materials or stiff boards to keep it smooth.

Protect from direct sunlight and humidity

Avoid direct sunlight and high humidity, which can damage the paper. Store it in a shaded, dry area for better longevity.

Conclusion

Kraft paper comes in various types, including virgin, recycled, and bleached options, each serving specific uses such as packaging, food safety, and branding. Understanding the properties of each type helps in choosing the best fit for your application, whether you need strength, moisture resistance, or printability.

When selecting Kraft paper, consider factors like strength, moisture resistance, and printing requirements. For eco-conscious choices, recycled Kraft is ideal, while bleached or coated types are best for clean, polished looks. Kraft paper's versatility makes it an excellent option for diverse industries.

Frequently Asked Questions (FAQ)

What is the strongest type of Kraft paper?

The strongest type is usually heavyweight or virgin Kraft paper, known for its durability and resistance.

Can Kraft paper be used for food packaging?

Yes, it is commonly used for food packaging, especially when untreated or coated for safety.

What’s the difference between bleached and unbleached Kraft paper?

Bleached Kraft paper is lighter in color and smoother, while unbleached retains its natural brown hue and texture.

Can you print on Kraft paper?

Yes, Kraft paper can be printed on, especially with offset or flexographic printing methods.

Reference Sources

[1] https://www.oren-intl.com/blog/bid/359426/6-types-of-kraft-paper-and-their-best-business-uses

[2] https://noissue.co/blog/a-guide-to-the-different-types-of-kraft-paper-and-how-to-use-them/

[3] https://info.primepac.co.nz/blog/types-of-kraft-paper-and-their-uses

[4] https://shreevarudi.com/blog-details/types-of-kraft-papers-its-uses

[5] https://www.wadpack.com/types-of-kraft-papers-and-its-uses/

[6] https://thelivelypack.com/7-types-of-kraft-paper-and-their-best-uses/

[7] https://en.wikipedia.org/wiki/Kraft_paper

[8] https://www.plgimpex.com/post/types-of-kraft-paper