Bible paper is unlike ordinary paper—thin yet durable, smooth yet resilient. Have you ever wondered what makes it so special? Unlike standard book paper, Bible paper must balance lightness and strength, ensuring thousands of delicate pages fit within a compact book without tearing easily.

In this post, we’ll explore the materials that make up Bible paper, from wood pulp and cotton fibers to special coatings that enhance opacity and print quality. You’ll also learn why it’s so thin, how it’s manufactured, and what makes it different from other specialty papers.

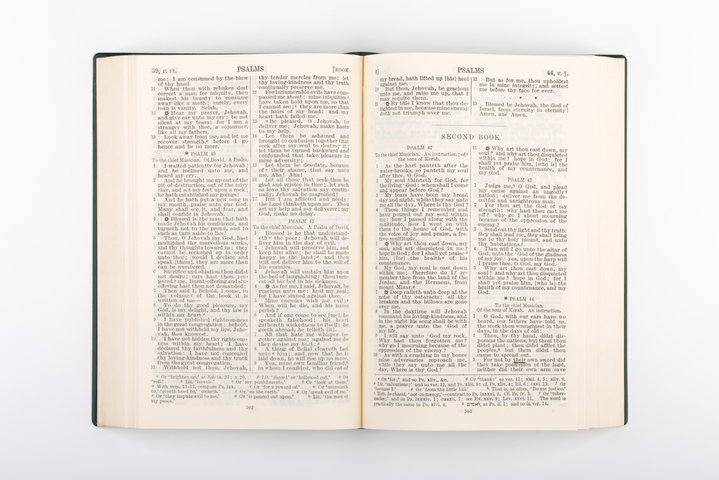

What Is Bible Paper?

Bible paper is a specialized, ultra-thin paper designed for books with a high page count but a compact size. It’s known for its durability, smooth texture, and high opacity, which prevents ink from bleeding through. Unlike regular book paper, Bible paper must be strong enough to withstand frequent use while remaining lightweight.

Definition and Characteristics

High Opacity – Prevents text from showing through the other side of the page.

Lightweight Yet Durable – Designed to handle frequent page turns without tearing.

Smooth Texture – Enhances print clarity, making small, dense text easier to read.

Flexible and Compact – Enables books to contain thousands of pages without becoming bulky.

How It Differs from Standard Paper

Bible paper is often compared to regular book paper, but they serve different purposes. The table below highlights key differences:

| Feature | Bible Paper | Standard Book Paper |

| Thickness | Ultra-thin (30-50 gsm) | Thicker (70-120 gsm) |

| Opacity | High to prevent show-through | Moderate, depends on quality |

| Durability | Tear-resistant, reinforced with additives | Less resistant to frequent use |

| Weight | Lightweight for high page counts | Heavier, bulkier |

| Finish | Smoother for fine printing | Varies (matte, glossy, textured) |

Common Uses Beyond Bibles

Dictionaries and Thesauruses – Allows for compact, easy-to-carry reference books.

Legal Documents – Used in legal publishing for storing vast amounts of text in a single volume.

Encyclopedias and Academic Books – Helps reduce the weight of multi-volume works.

Luxury Editions of Classic Literature – Often found in collector’s editions for its elegant, thin pages.

Materials Used in Bible Paper Production

Bible paper requires a delicate balance of thinness, durability, and printability. Achieving this involves a precise mix of raw materials and specialized additives.

1. Primary Raw Materials

Bible paper isn’t made from ordinary paper pulp. Instead, manufacturers use a refined blend of materials to enhance strength, flexibility, and longevity.

Wood Pulp

Most Bible paper comes from high-quality wood pulp, typically sourced from softwoods like spruce and fir. These trees produce long fibers, increasing tear resistance while keeping pages thin. The pulp undergoes chemical treatment to remove lignin, preventing yellowing and ensuring the paper remains bright over time.

Cotton and Linen Fibers

Cotton and linen fibers are often added to improve the texture and lifespan of Bible paper. They provide extra durability, making pages less prone to tearing or crinkling. Cotton-based paper also gives a smooth, slightly glossy finish, allowing for crisp, detailed printing.

Synthetic Fibers

Manufacturers sometimes incorporate synthetic fibers such as polyester or nylon to reinforce Bible paper. These fibers enhance tensile strength, reducing the risk of damage from frequent handling. They also contribute to the paper’s unique flexibility, preventing creases and making it easier to turn pages.

2. Special Additives

Bible paper contains various additives that improve its appearance, readability, and performance. These substances ensure optimal opacity, brightness, and ink absorption.

Calcium Carbonate and Clay

Calcium carbonate and clay are essential fillers that increase opacity, preventing text from showing through the thin pages. They also create a smoother surface, improving print clarity and making small fonts easier to read. The use of these minerals helps balance paper weight while maintaining strength.

Gelatin or Starch Coatings

A thin coating of gelatin or starch is applied to Bible paper to enhance ink absorption and smoothness. This coating prevents ink from spreading, ensuring sharp, legible text. It also gives the paper a slightly glossy finish, reducing friction and making page-turning effortless.

Titanium Dioxide

Titanium dioxide is a whitening agent that boosts paper brightness and extends its lifespan. It helps maintain the paper’s crisp, clean look, even after years of use. This additive also provides UV resistance, protecting pages from discoloration due to light exposure.

How Is Bible Paper Made?

Bible paper requires a precise manufacturing process to achieve its lightweight yet durable structure. From selecting raw materials to refining the final product, every step ensures it remains thin, strong, and high-quality.

1. Manufacturing Process Overview

Pulp Preparation: Wood pulp, cotton, and synthetic fibers are blended to create a strong but lightweight base. The pulp undergoes chemical processing to remove lignin, preventing yellowing over time.

Refining and Beating: The fibers are refined to enhance bonding strength. Beating increases flexibility, ensuring the paper remains thin yet tear-resistant. Cotton fibers are sometimes added for extra durability.

Sheet Formation: The processed pulp is spread onto a fine mesh screen, draining excess water while forming a uniform sheet. Special techniques control thickness and weight, ensuring consistency across batches.

Pressing and Drying: Pressing removes excess moisture, compressing fibers for added strength. Afterward, the paper is passed through heated rollers, fully drying it while maintaining smoothness and flexibility.

Coating and Sizing: A thin layer of gelatin or starch is applied to enhance ink absorption and prevent smudging. Some manufacturers add calcium carbonate or clay to improve opacity, reducing text visibility from the other side.

Calendering and Cutting: The final step involves calendering—running the paper through rollers to achieve a polished, smooth finish. The sheets are then cut into desired sizes, ready for printing.

2. Comparison With Other Thin Papers

Bible paper is often mistaken for other ultra-thin papers, but it has distinct differences from materials like onion skin paper.

| Feature | Bible Paper | Onion Skin Paper |

| Thickness | 30-50 gsm | 25-40 gsm |

| Opacity | High, reducing text show-through | Moderate, some transparency |

| Durability | Tear-resistant, reinforced with fibers | Fragile, crinkles easily |

| Coating | Gelatin or starch for smoothness | Little to no coating |

| Primary Use | Bibles, dictionaries, legal books | Typewriters, archival documents |

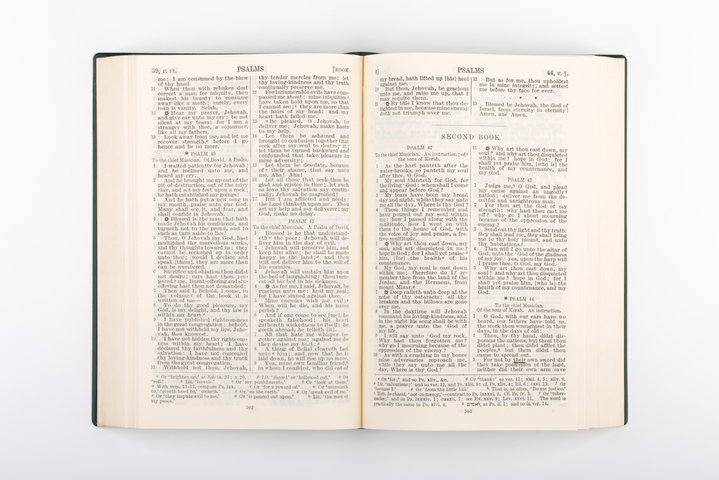

Key Properties of Bible Paper

1. Thin Yet Durable

Bible paper is incredibly thin but surprisingly durable. Despite its light weight, it's made with a special process that strengthens the fibers, allowing it to withstand wear and tear. This durability ensures that the pages don’t easily tear, even though they are very thin.

2. High Opacity

3. Smooth Texture for Print Quality

Bible paper has a smooth, almost silky texture that makes it ideal for high-quality printing. This smoothness ensures that fine, dense text can be printed clearly without bleeding or blurring, which is essential when handling small font sizes in compact spaces.

4. Lightweight and Flexible

Despite its high opacity and smooth texture, Bible paper is lightweight and flexible. This makes it perfect for creating compact, portable books that can carry large amounts of text without being bulky. The flexibility adds to the ease of handling, allowing the pages to turn smoothly without damage.

Why Is Bible Paper So Thin?

Historical Reasons for Thin Pages

Cost Efficiency: Paper used to be costly and difficult to produce, so thinner sheets allowed for the inclusion of more text without inflating the cost of the Bible.

Resource Conservation: By using thinner paper, manufacturers could produce more copies of the Bible with limited resources, making it a more accessible option for a wider audience.

Space Efficiency: Thin paper enabled a compact format, allowing more content to fit in a smaller book. This helped keep Bibles lightweight and easy to handle.

The Necessity of Compactness for Carrying Bibles

Portability: A thinner paper makes it easier to carry a Bible in everyday bags or even in pockets, making it ideal for people on the go.

Easier Reading: With thinner paper, the Bible remains manageable, allowing readers to comfortably hold and navigate through its many pages without discomfort.

Convenience: Thin paper ensures that the Bible doesn’t become too bulky, even though it may contain a large volume of text, making it convenient for daily use and travel.

How Technological Advancements Have Influenced Thin Paper Production

Stronger Paper Fibers: Modern papermaking techniques have enabled the creation of thinner paper with stronger fibers, improving durability while maintaining a light weight.

Advanced Printing Technology: The use of finer printing presses ensures that text remains sharp and legible, even when printed on the thin Bible paper.

Improved Pulping Techniques: Modern pulping methods allow for the production of fine paper that doesn’t sacrifice strength for thinness, helping Bibles maintain their quality despite being lightweight.

Different Types of Bible Paper

| Type of Bible Paper | Characteristics | Common Uses |

| Standard Bible Paper | Lightweight, thin, and durable. Smooth texture for clear printing. | Used in standard Bibles, balancing cost and durability. |

| Premium Bible Paper | Higher durability, smoother surface, acid-free properties for longevity. | Used in high-quality Bibles designed for long-lasting use. |

| India Paper | Ultra-thin, high-opacity, compact design with fine texture. | Commonly used in luxury or collector's editions of Bibles. |

| Recycled Bible Paper | Made from recycled materials, eco-friendly and sustainable. | Increasingly used in eco-friendly Bibles, appealing to sustainability-conscious readers. |

Challenges in Printing on Bible Paper

1. Ink Absorption Issues

Ink absorption is a significant challenge when printing on thin Bible paper. Because the paper is so porous, ink can bleed through to the other side, making the text difficult to read, especially with fine or dense fonts. To prevent this, printers use specialized inks and techniques, such as oil-based inks or thin layers of ink. Some high-quality Bible editions also include coatings to reduce ink absorption and ensure the text remains crisp and clear.

2. Durability and Wear Over Time

Bible paper is thin, which makes it prone to yellowing and tearing over time. This is especially true when the Bible is frequently used or exposed to light and air. To combat this, manufacturers use archival-quality coatings that help preserve the paper's integrity. These coatings prevent yellowing and help maintain the Bible's readability and durability for longer periods.

3. Binding Considerations

Thin pages present challenges for bookbinding. Because Bible paper is so delicate, it can tear or become loose if the binding isn’t secure. Binding methods like Smyth sewing or reinforced bindings are often used to ensure the Bible lasts. These techniques help keep the pages intact and ensure the Bible holds up to frequent handling while remaining flexible and durable.

How to Care for Bible Paper

1. Preventing Tearing and Wrinkling

Handling Bible paper with care is essential to prevent tearing and wrinkling. Always hold the Bible by the spine or edges, never by the pages. Avoid bending or folding the pages, and be mindful of how much pressure you apply when turning the pages. Gently turning each page will help preserve the thin, delicate paper and prevent creases or damage over time.

2. Storage and Humidity Control

Bible paper is sensitive to moisture, which can lead to warping or mold growth. Store your Bible in a dry, cool place away from direct sunlight, which can cause the paper to fade or become brittle. Using a protective cover can also help shield the Bible from humidity. If you live in a humid area, consider using a dehumidifier to control moisture levels.

3. Cleaning and Preservation

When cleaning your Bible, always use a soft, dry cloth to gently wipe away dust and dirt. Avoid using water, as it can damage the delicate paper. For stubborn stains, lightly dab the area with an eraser designed for delicate paper. Additionally, consider using acid-free storage materials, such as archival-quality boxes or sleeves, to preserve the pages for future generations.

Bible Paper vs. Other Specialty Papers

| Comparison | Bible Paper | Onion Skin Paper | Regular Book Paper | Carbonless and Thermal Papers |

| Texture | Thin, smooth, slightly translucent. | Thin, smooth, and very crisp. | Thicker, more textured and rigid. | Carbonless: smooth, Thermal: coated. |

| Primary Use | Primarily used for compact Bibles. | Common in old typewriters. | Used for novels and general publications. | Carbonless: receipts; Thermal: receipts. |

| Durability | Durable but sensitive to handling. | Extremely fragile, prone to tearing. | More robust, designed for heavy use. | Carbonless: sturdy; Thermal: heat-sensitive. |

| Thickness | Very thin for compact book design. | Extremely thin, almost tissue-like. | Generally thicker, designed for durability. | Carbonless: thin; Thermal: varies. |

1. Bible Paper vs. Onion Skin Paper

Both Bible paper and onion skin paper are thin, but Bible paper is smoother and more translucent, designed specifically for the dense text of Bibles. Onion skin paper, while also thin, has a crisper texture and was more commonly used in typewriters. Onion skin is much more fragile, making it unsuitable for heavy handling compared to Bible paper.

2. Bible Paper vs. Regular Book Paper

The primary difference between Bible paper and regular book paper lies in thickness. Bible paper is much thinner, allowing for compact Bibles, but this makes it more prone to damage. Regular book paper, thicker and more durable, is better suited for everyday use in novels and textbooks, where longevity is key.

3. Bible Paper vs. Carbonless and Thermal Papers

Bible paper is thinner and made to preserve printed text over time, whereas carbonless and thermal papers are designed for specific applications. Carbonless paper is used for duplicate forms and is smooth, while thermal paper is coated to react to heat. These papers are more specialized, focusing on immediate print needs rather than longevity.

Conclusion

Bible paper stands out for its thinness, durability, and opacity, making it ideal for compact Bibles. Technological advancements have helped maintain its strength and print clarity. Looking ahead, innovations in Bible paper production will focus on sustainability and improved durability.

Encouraging eco-friendly alternatives and recyclable materials is crucial in reducing the environmental impact of Bible paper. The development of biodegradable and sustainable options will play a key role in the future of thin paper manufacturing.

FAQs

1. Can Bible paper be recycled?

Yes, Bible paper is generally recyclable, but due to its thinness and coatings, some recycling facilities may not accept it. Check local recycling guidelines.

2. Why does Bible paper turn yellow over time?

Bible paper can yellow due to acid content in lower-quality paper or prolonged exposure to light, humidity, and air pollutants. Acid-free paper lasts longer without discoloration.

3. Is there a waterproof version of Bible paper?

Some premium Bible editions use synthetic or coated paper that resists water damage, but standard Bible paper is highly absorbent and not waterproof.