PE Coated Paper Suppliers In China

- Supports a variety of high-quality custom printing services

- High quality, good brightness, high opacity, and good stiffness

- Competitive pricing and low minimum order quantities

- Free samples with worldwide delivery

- Compliant with food safety regulations

One Of The Best PE Coated Paper Manufacturers in China

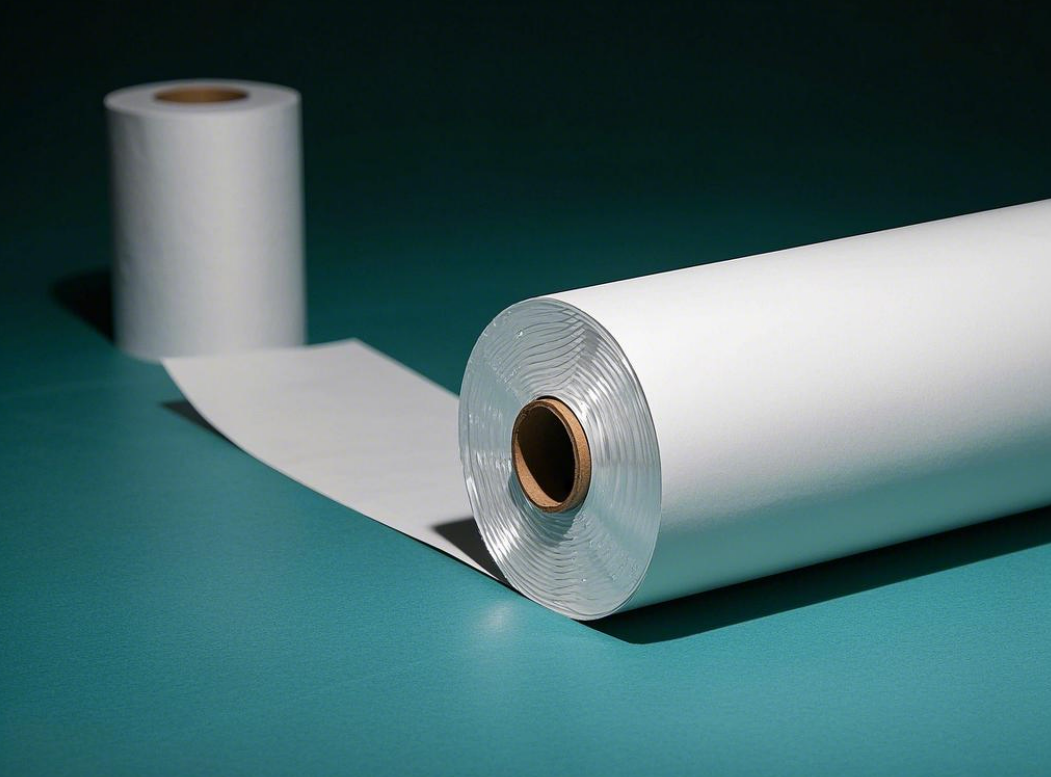

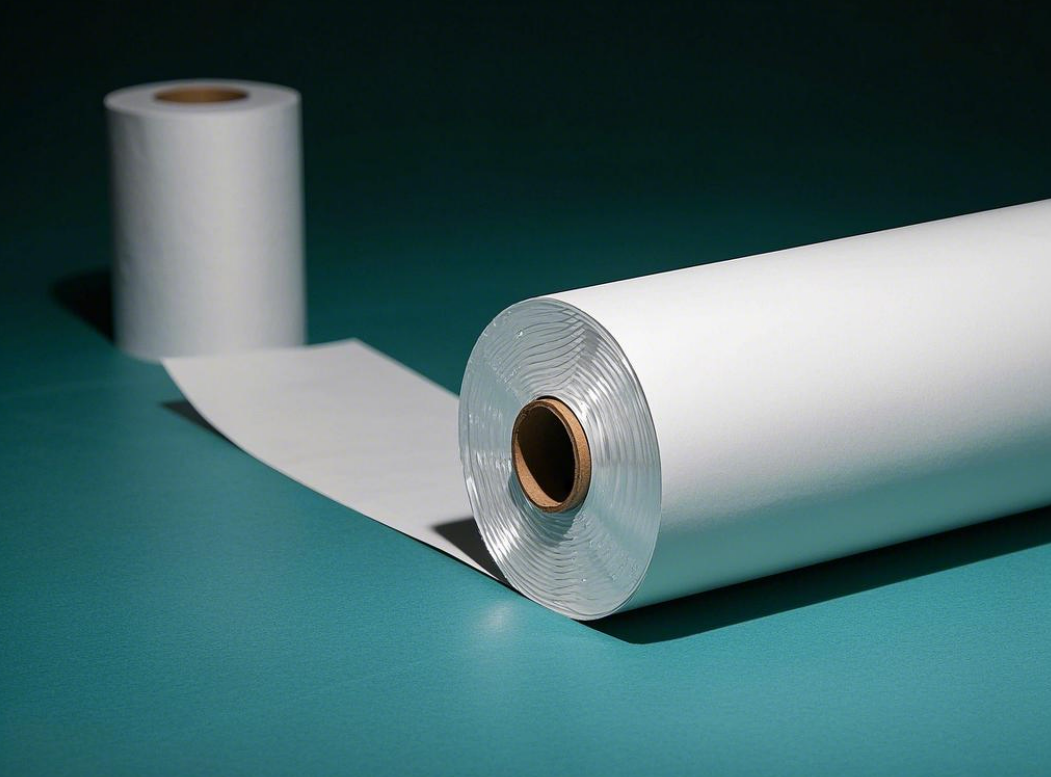

PE coating paper is a kind of paper roll upon which polyethylene is coated to resist wetness and grease attack. The coating material (PE film) is heated and made into a very thin film not exceeding 0.04 cm in thickness. The hot film is bonded with surface paperboard to create an exterior layer.

AS a professional release paper manufacturer with nearly 20 years of production and sales experience. Sunrise offer one-stop production from pure wood pulp raw paper to finished products, including food-grade PE coated paper, cup fans, cup bottoms, and even paper boxes, cups, and bowls. Our products feature food-grade standards, smooth surfaces, single or double-sided PE coating, and eco-friendly base paper. They are suitable for various applications such as paper cups, ice cream cups, snack packaging bowls, and food containers.

Let Sunrise custom your particular needs. Contact us today!

Sunrise - Your Professional PE Coated For Paper Up Manufacturer

The Features Of PE Coated Paper

Sunrise's PE Coated Paper offers a range of features that make it an ideal choice for various food packaging applications. With its superior performance, safety, and versatility, this product enhance your brand.

Heat Resistance

Withstands temperatures up to 100°C, preventing cups from deforming or damage when filled with hot beverages. Ensures the structural integrity of the container during use.

Liquid Barrier

PE coating completely prevents liquid penetration, eliminating leaks. Keeps the contents secure and maintains the freshness of the food or beverage inside the packaging.

Food-Grade Base Material

Manufactured using pure wood pulp, complying with international food safety standards. Suitable for direct food contact packaging without any harmful chemical substances.

Excellent Printability

Supports various printing methods with surface treatment for accurate color reproduction, clear images, strong ink adhesion, and scratch resistance. Enhances brand image.

Wide Applicability

Suitable for both hot and cold food packaging, such as coffee, tea, and soup. Versatile packaging solution for various food service needs.

Dimensional Stability

Maintains its original shape during use, preventing rim deformation, bottom weakening, or sidewall collapse. Offers a reliable and sturdy packaging option for various applications.

Widely Used For Industry

Catering Industry

Our PE Coated Paper is used as wrapper, oil paper bowl, and coffee cup in the catering industry. It serves as baking and oil-proof paper. The paper is also utilized as steamer basket padding. These applications leverage the paper's resistance to oil and moisture.

Hygienic Materials

The PE Coated Paper also used in sanitary towels and pads. The paper is a component of disposable diapers. It is also utilized in regular diapers. These applications leverage the paper's absorbency, softness, and ability to prevent leakage.

Medical Industry

The PE Coated Paper by Sunrise is used for band-aids and plaster patches in the medical industry. The paper serves as a base for infusion plasters. It is also utilized in fever cooling patches. These applications benefit from the paper's breathability and skin-friendly properties.

Why Sunrise PE Coated Paper

OEM Expertise

With 20 years of OEM experience serving thousands of clients worldwide, Sunrise has the knowledge and capabilities to handle diverse custom manufacturing requirements. The company's extensive track record demonstrates its reliability and proficiency in delivering tailored solutions to customers across the globe.

Reliable Delivery

With a commitment to stable and efficient delivery times, Sunrise ensures that customers receive their orders promptly and consistently. The company's streamlined production processes and logistical expertise enable it to meet tight deadlines and accommodate urgent requests without compromising quality.

After-Sale Support

Sunrise provides worry-free after-sale service to ensure customer satisfaction long after the initial purchase. The company's dedicated support team is readily available to address any concerns, answer questions, and provide assistance, giving customers peace of mind and fostering long-term relationships.

Competitive MOQ

Sunrise offers competitive prices and lower minimum order quantities (MOQ) for its custom paper cup fans. This makes the company's products accessible to a wide range of customers, from small businesses to large event organizers, ensuring that everyone can benefit from Sunrise's high-quality, eco-friendly solutions.

One-stop PE Coated Paper Factory in China

9 Production Facilities

50000 Annual Production

12 Hour Service Response

PE Coated Paper: The ultimate FAQ Guide

What is PE?

Polyethylene (PE) is a versatile thermoplastic polymer derived from petroleum that serves as the primary coating material for PE coated paper. This milky white, waxy substance is odorless, non-toxic, and provides excellent water resistance, making it ideal for paper packaging applications.

Factors to Consider When Choosing PE Coated Paper

Product Type (Fragility, Weight, Size)

- LDPE coating: Ideal for lightweight, flexible packaging

- HDPE coating: Better for rigid, more protective packaging needs

- Coating thickness: 10-20 GSM depending on protection requirements

Budget Constraints

- Single-sided coating: More economical option

- Double-sided coating: Higher cost but maximum protection

- PE coating type affects overall price point

Environmental Concerns

| PE Type | Recyclability | Biodegradability | Environmental Impact |

|---|---|---|---|

| LDPE | Recyclable but challenging | Not readily biodegradable | Moderate |

| HDPE | More widely recycled | Not readily biodegradable | Lower than LDPE |

Branding and Aesthetics

- Matte finish: Non-reflective surface for premium look

- Glossy finish: Vibrant, attention-grabbing appearance

- Excellent printability for brand messaging

Best Use Cases

When selecting packaging, consider these application guidelines:

- Food packaging: Use PE with 15-20 GSM for moisture-resistant containers

- Product labels: Choose PE coated paper with matte finish for premium products

- Cold beverages: Double-sided PE coating prevents condensation damage

- Hot food items: Single-sided PE with heat-seal capability

Industry-Specific Recommendations

Different industries benefit from specific PE coated paper configurations:

- Retail Packaging: Glossy PE coating enhances shelf appeal

- Shipping & Logistics: Water-resistant PE prevents damage during transit

- Consumer Goods: Food-safe PE grades for direct food contact

- Creative Industries: Flexible, printable PE surfaces for custom designs

The right PE coating selection ensures optimal product protection while meeting budget and environmental objectives.

What are the composition and properties of PE coated paper?

PE coated paper combines the structural integrity of paper with the protective qualities of polyethylene, creating a versatile packaging material used across multiple industries.

Manufacturing process of PE coated paper

Two primary methods are used to create PE coated paper:

- Extrusion Coating: Molten polyethylene is applied directly to the paper surface as it passes through specialized machinery, creating a strong bond between the paper and coating.

- Lamination Process: Pre-formed PE film is pressed onto paper under controlled heat and pressure, resulting in a secure adhesion between layers.

Composition of PE coated paper

| Component | Function | Characteristics |

|---|---|---|

| Base Paper | Provides structure and stability | Typically kraft, white, or bamboo-based |

| PE Coating | Delivers protective barrier | Usually LDPE, thickness 10-20 GSM |

Properties of PE coated paper

PE coated paper offers multiple performance advantages:

- Water resistance: Creates an effective barrier against moisture, preventing the paper from becoming soggy

- Grease and oil resistance: Stops oils from penetrating through packaging, keeping exterior surfaces clean

- Heat sealability: Allows package edges to be sealed through heat application, creating secure closures

- Chemical inertness: Remains stable when in contact with various substances, making it food-safe

- Flexibility: Enhances paper flexibility while maintaining structural integrity

- Printability: Provides excellent surface for high-quality graphics and branding, especially with glossy finishes

These properties make PE coated paper an ideal solution for applications requiring both paper's versatility and plastic's protective qualities.

What are the different types of PE coated paper?

PE coated paper comes in several variations, each designed for specific applications and performance requirements.

Types of PE Coated Paper by Coating Configuration

| Type | Description | Primary Applications |

|---|---|---|

| Single-side PE coated paper | Features PE coating on one side only | Hot beverage cups, hamburger wrappers, fast food packaging |

| Double-side PE coated paper | Contains PE coating on both sides | Cold drink cups, ice cream containers, frozen food packaging |

| Sandwich PE coated paper | PE layer between two paper sheets | Desiccant packaging, food packaging bags, enhanced moisture barrier applications |

| Release liner PE coated paper | Special coating prevents adhesive sticking | Labels, tapes, pressure-sensitive adhesive applications |

Types of PE Coated Paper by Surface Finish

Different surface finishes offer varied aesthetic and functional properties:

- Matte PE coated paper

- Non-reflective, sophisticated appearance

- Superior print clarity and readability

- Ideal for high-quality product labels and premium packaging

- Enhanced visibility in bright lighting conditions

- Glossy PE coated paper

- Shiny, reflective surface

- Vibrant color enhancement

- Commonly used for paper cups and eye-catching packaging

- Creates standout visual appeal on retail shelves

In which applications and uses is PE coated paper commonly found?

PE coated paper's versatility makes it an essential material across numerous industries. Its water resistance, durability, and printability create the perfect combination for various applications.

Primary Applications by Industry

Food Packaging Solutions

PE coated paper dominates the food industry with applications including:

- Hot food containers: Paper cups, soup cups with single-side PE coating

- Cold food containers: Salad bowls, ice cream containers with double-side coating

- Food service items: Paper lids, disposable utensil wraps

- Takeout packaging: Bags, boxes, wrappers with grease resistance

Medical and Healthcare Uses

- Sterile instrument wrappers

- Pharmaceutical packaging

- Disposable bed sheets and covers

Publishing and Creative Industries

| Application | PE Coating Benefit | Common Examples |

|---|---|---|

| Printing | Enhanced color vibrancy | Brochures, magazines |

| Specialty papers | Water-resistant durability | Maps, outdoor signage |

| Bookbinding | Smooth, glossy surface | Book covers, dust jackets |

| Art and craft | Moisture resistance | Scrapbooking, origami |

Home and Lifestyle Products

- Décor elements: Wallpaper with washable surfaces

- Gifting: Wrapping paper, gift bags with aesthetic appeal

- Textiles: Specialized paper-based fabric applications

- Retail packaging: Cosmetic boxes, toy packaging, electronics boxes

Everyday Items

PE coated paper is also commonly found in disposable tableware, labels and stickers, and various consumer products where protection from moisture or grease is essential.

What are the benefits of using PE coated paper?

PE coated paper delivers multiple advantages that make it the preferred choice for packaging across various industries. These benefits combine to create a versatile material that outperforms traditional uncoated paper in challenging environments.

Key Benefits of PE Coated Paper

| Benefit | Performance Level | Applications |

|---|---|---|

| Moisture Resistance | Excellent | Food containers, outdoor packaging |

| Grease/Oil Resistance | Good to Excellent | Fast food wrappers, fried food packaging |

| Heat Sealability | Very Good | Sealed pouches, secure food packaging |

| Chemical Inertness | Good | Food-safe applications, medical packaging |

| Flexibility | Excellent | Bags, wraps, folded containers |

| Printability | Very Good | Branded packaging, retail displays |

Moisture Resistance Advantage

PE coating creates a near-impermeable barrier against water, preventing paper from becoming soggy or deteriorating when exposed to liquids. At just 10 GSM coating thickness, PE coated paper provides sufficient waterproofing for most applications.

Protection from Oils and Grease

The polyethylene layer effectively blocks oils and greases from penetrating the paper structure, keeping exteriors clean and preventing staining—crucial for food service packaging.

Additional Performance Benefits

- Heat sealability: Enables secure package closure without adhesives

- Chemical inertness: Remains stable when contacting various substances, making it food-safe

- Flexibility: Maintains structural integrity while allowing easy folding and shaping

- Branding excellence: Supports high-quality printing for vibrant logos and marketing messages

What are the disadvantages of using PE coated paper?

While PE coated paper offers numerous benefits, it also comes with several limitations that manufacturers and consumers should consider before choosing this material for their applications.

Key Limitations of PE Coated Paper

- Gas Permeability Issues: Despite excellent moisture resistance, PE coating offers poor oxygen barrier properties, making it unsuitable for long-term food preservation

- Odor Transmission: The coating allows odors to pass through, potentially affecting product quality and user experience

- Temperature Sensitivity: Limited heat resistance (80-100°C), restricting use in microwave and high-temperature applications

Environmental Challenges

| Challenge | Description | Impact |

|---|---|---|

| Recycling Complexity | Requires specialized hydro pulping to separate PE from paper | Increases recycling costs and reduces recovery rates |

| Non-biodegradable Nature | PE coating persists in the environment for hundreds of years | Contributes to long-term environmental pollution |

| Fossil Fuel Dependency | Production requires petroleum-derived resources | Increases carbon footprint and resource depletion |

Practical Considerations

- Production & Processing Challenges:

- Difficulty in printing without special treatments or inks

- Requires specialized equipment for manufacturing and processing

- More expensive than uncoated paper alternatives

- Sustainability Concerns:

- Not compostable in standard facilities

- Contributes to plastic waste accumulation

- Challenging to incorporate into circular economy models

How does PE coated paper compare with other types of coated and uncoated papers?

Comparative Analysis of Paper Types

| Performance Factor | PE Coated Paper | Wax Coated Paper | Clay Coated Paper | Uncoated Paper |

|---|---|---|---|---|

| Water Resistance | Excellent | Good | Poor to Moderate | Poor |

| Grease Resistance | Excellent | Good | Poor | Poor |

| Structural Integrity | High | Moderate | Moderate | Low |

| Printability | Good (requires special inks) | Limited | Excellent | Very Good |

Water and Moisture Resistance

PE coated paper significantly outperforms other options in moisture protection. While uncoated paper absorbs water immediately and loses structural integrity, PE coating creates a nearly impermeable barrier that maintains the paper's form and function even when exposed to liquids.

Grease and Oil Resistance

- PE coated paper: Prevents oil penetration completely

- Wax coated paper: Provides temporary resistance

- Clay coated/Uncoated: Quickly absorbs oils, causing staining

Structural Integrity Benefits

PE coating enhances paper's durability by:

- Preventing fiber separation when wet

- Adding tensile strength

- Improving tear resistance

- Maintaining shape under stress

Printing Capabilities Comparison

Though PE coating presents some printing challenges compared to clay-coated papers, modern printing technologies have largely overcome these limitations. While uncoated papers offer excellent ink absorption, they lack the protective qualities essential for many applications.

What are the quality control and testing methods for PE coated paper?

Ensuring PE coated paper meets strict quality standards is essential for maintaining product integrity across various applications. Comprehensive quality assurance protocols safeguard both performance and safety.

Quality Control Process Flow

Quality assurance for PE coated paper follows a systematic approach:

- Raw Material Inspection

- Verification of paper base quality (tears, wrinkles, contaminants)

- PE resin testing for molecular weight and melt flow index

- Additive quality assessment for consistency

- Process Control Measures

- Continuous monitoring of extrusion temperature profiles

- Coating weight measurement and adjustment

- Adhesion parameters verification during production

- Finished Product Inspection

- Visual examination for coating uniformity

- Dimensional stability checks

- Surface quality assessment

Critical Testing Methods

| Test Type | Procedure | Acceptance Criteria |

|---|---|---|

| Water Resistance | Sample submersion for specified time period | No penetration, minimal softening |

| Grease Resistance | Application of standardized oils at controlled temperatures | No staining or penetration after set period |

| Tensile Strength | Controlled force application until material failure | Meets minimum strength requirements |

Regulatory Framework

PE coated paper must adhere to multiple regulatory standards:

- FDA Regulations: Materials must be food-safe with approved additives for food contact applications

- ASTM Standards: ASTM D6868 for compostability; ASTM F119-82 for steam resistance

- European Regulations: EU 10/2011 on plastic materials contacting food; EFSA guidelines on migration limits

Is PE coated paper safe?

Yes, PE coated paper is safe for food contact. Polyethylene is chemically inert and doesn't react with food or alter flavor. Manufacturers must pass rigorous FDA and EU certification processes before their products can be used for food packaging applications.

Is PE coated paper recyclable?

PE coated paper is technically recyclable but requires specialized processing:

- Requires hydro pulping to separate PE coating from paper fibers

- More complex and expensive than standard paper recycling

- Not accepted in all recycling programs

- Check local recycling guidelines before disposal

What is the difference between single-side and double-side PE coated paper?

| Feature | Single-Side PE Coated | Double-Side PE Coated |

|---|---|---|

| Coating Location | One side only | Both sides |

| Primary Uses | Hot beverage cups, burger wrappers | Cold drinks, ice cream containers |

| Moisture Protection | Internal only | Both internal and external |

| Condensation Handling | Limited | Excellent |

| Cost | Lower | Higher |

Can PE coated paper be used in the microwave?

No, PE coated paper is not microwave-safe. The coating has low temperature resistance (80-100°C) and may release potentially harmful substances when heated beyond this threshold.

How does the thickness of the PE coating affect the paper's properties?

Coating thickness (measured in GSM) directly impacts functionality:

- 10 GSM: Basic water/moisture resistance

- 12-15 GSM: Suitable for adhesive applications

- 18-20 GSM: Optimal for heat-sealing capabilities

What is PE-lined paper?

PE-lined paper is another term for PE coated paper. Both refer to paper with a polyethylene layer applied to one or both surfaces to enhance water resistance and other protective properties.

Is PE coated paper biodegradable?

No, PE coated paper is not biodegradable. While the paper substrate would naturally decompose, the polyethylene coating persists in the environment for hundreds of years. For eco-friendly alternatives, consider papers with PLA or other biodegradable coatings.

Submit a Quick Quote

Kraft Paper Sheets:A Comprehensive Guide

Coated vs Uncoated Paper: A Comprehensive Guide

Can You Microwave A Paper Cup?