Have you ever struggled with paper weight conversions for your projects? Whether you're printing marketing materials, packaging products, or crafting custom invitations, understanding paper weight is crucial. A Paper Weight Conversion Chart helps you navigate various systems like GSM, basis weight, and points, ensuring you select the right paper for your needs.

In this guide, we’ll break down the most common measurement systems and how they impact your paper choices—making it easier for you to pick the perfect paper every time.

Understanding Paper Weight Measurements

Common Paper Weight Measurement Systems

Paper weight measurements vary across different regions and industries, making it essential to understand the commonly used systems. Understanding these measurement systems is essential when using a Paper Weight Conversion Chart to compare different paper types. By knowing the relationships between basis weight, GSM, points, and caliper, businesses and designers can make informed choices for printing, packaging, and crafting needs.

This section explores four key measurement methods: Basis Weight (lbs), GSM (Grams per Square Meter), Points (pt), and Caliper.

Basis Weight (lbs) – Used in the U.S.

Basis weight is the standard measurement in the U.S. paper industry, defined as the weight of 500 sheets (a ream) of a specific paper type at its basic size before trimming. Since different paper types have varying basic sizes, the same numerical basis weight can represent different thicknesses. For example:

Understanding basis weight is crucial when selecting paper for printing and packaging, as heavier weights indicate thicker and more durable paper.

GSM (Grams per Square Meter) – Global Standard

GSM (g/m²) measures paper weight based on the weight of one square meter of paper, regardless of its type. Unlike basis weight, GSM provides a direct and consistent comparison between different papers. Common GSM values include:

75-90 GSM – Standard printer paper

120-150 GSM – Brochures and flyers

200-350 GSM – Business cards and premium packaging

Because GSM is independent of paper size, it is widely used internationally and preferred for accurate weight comparisons.

Points (pt) – Used in Packaging and Cardstock

Points (pt) measure paper thickness rather than weight, commonly used for cardstock and packaging materials. One point equals 0.001 inches, meaning a 10 pt paper is 0.01 inches thick. Typical examples include:

10-12 pt – Postcards and light packaging

14-16 pt – Premium business cards

18-24 pt – Rigid packaging and specialty applications

Since points measure thickness, they do not directly correlate with GSM or basis weight, but they are crucial for selecting sturdy paper for high-quality prints and packaging.

Caliper (Thickness) – Relevance in the Printing Industry

Caliper refers to the actual thickness of paper, measured in thousandths of an inch (mils). This measurement is particularly important in high-end printing, where precise thickness affects print quality and machine compatibility. Typical values include:

0.003"-0.005" – Lightweight paper for books and magazines

0.010"-0.016" – Cardstock and premium prints

0.020" and above – Heavy-duty packaging

How Paper Weight Affects Usage

Selecting the appropriate paper weight is essential for ensuring optimal performance in different applications. The weight of paper influences its durability, printability, and suitability for specific tasks. Below are key areas where paper weight plays a crucial role.

Printing and Copying

For everyday office printing, lightweight paper is preferred due to its cost-effectiveness and compatibility with most printers. Standard options include:

75-90 GSM (20-24 lb bond paper) – Common for office documents, reports, and invoices.

100-120 GSM (28-32 lb bond paper) – Used for high-quality presentations, resumes, and double-sided printing to minimize ink bleed-through.

In commercial printing, heavier weights are necessary for durability and professional aesthetics:

130-170 GSM (text paper) – Ideal for brochures, flyers, and posters.

200-250 GSM (cover paper) – Suitable for high-end marketing materials, menus, and magazine covers.

Packaging and Labeling

Packaging materials require thicker, more rigid paper to withstand handling and transport. The weight selection depends on the intended use:

250-300 GSM (light cardstock, 90-110 lb cover paper) – Common for product boxes, lightweight cartons, and luxury paper bags.

300-400 GSM (heavy cardstock, 12-16 pt) – Preferred for rigid packaging, business cards, and durable hang tags.

Above 400 GSM (extra-thick board) – Used for premium packaging, book covers, and structural applications.

Labels also require the right paper weight based on adhesion and durability:

70-90 GSM – Standard labels for shipping and mailing.

100-150 GSM – Premium product labels with a glossy or matte finish.

Above 200 GSM – Heavy-duty labels for industrial and outdoor applications.

A Paper Weight Conversion Chart helps manufacturers and designers determine the best paper weight for packaging needs while balancing cost and durability.

Specialty Paper for Crafting and Professional Applications

For crafting, invitations, and artistic projects, paper weight influences texture, cutting ease, and printing quality:

120-180 GSM – Scrapbooking, origami, and DIY greeting cards.

200-300 GSM – Wedding invitations, fine art prints, and professional photography paper.

Above 350 GSM – Letterpress printing, embossed stationery, and premium handmade cards.

Wholesale 60GSM 70GSM 80GSM white offset paper/wood free offset paper

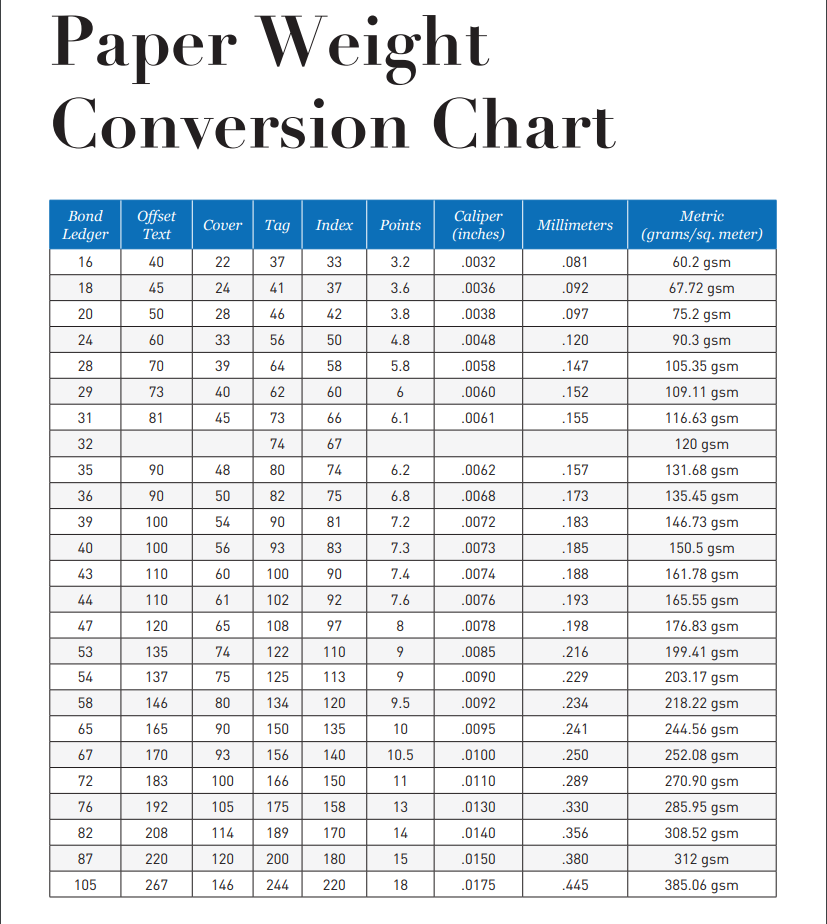

Paper Weight Conversion Chart

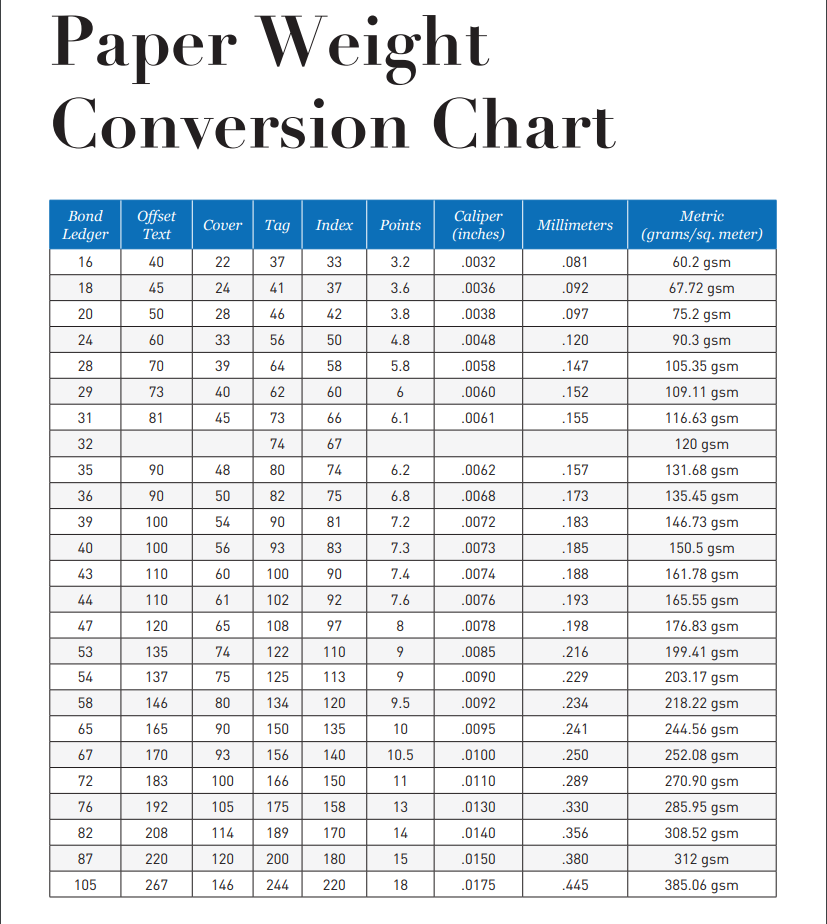

Understanding the relationship between different paper weight measurement systems is essential for selecting the right material for printing, packaging, and specialty applications. The following Paper Weight Conversion Chart provides a detailed comparison of basis weight (lbs), GSM (grams per square meter), and points (pt) for various paper types.

Comprehensive Paper Weight Conversion Table

This expanded table includes a wide range of paper weights, providing more precise conversions for different paper grades.

| Paper Type | Basis Weight (lbs) | GSM (g/m²) | Thickness (pt) | Common Uses |

| Bond Paper | 16 lb | 60 GSM | ~2.5 pt | Lightweight office paper, faxes |

| Bond Paper | 20 lb | 75 GSM | ~3 pt | Standard printer and copier paper |

| Bond Paper | 24 lb | 90 GSM | ~4 pt | Business stationery, letterheads |

| Bond Paper | 28 lb | 105 GSM | ~4.5 pt | High-quality reports, presentations |

| Bond Paper | 32 lb | 120 GSM | ~5 pt | Premium marketing materials, brochures |

| Text Paper | 50 lb | 75 GSM | ~3 pt | Lightweight books, low-cost flyers |

| Text Paper | 60 lb | 90 GSM | ~4-5 pt | Brochures, high-end magazines |

| Text Paper | 70 lb | 105 GSM | ~5 pt | Posters, catalogs, promotional materials |

| Text Paper | 80 lb | 120 GSM | ~6 pt | Premium brochures, restaurant menus |

| Text Paper | 100 lb | 150 GSM | ~7-8 pt | High-end marketing prints, magazine covers |

| Cover Paper | 65 lb | 175 GSM | ~7 pt | Postcards, greeting cards |

| Cover Paper | 80 lb | 215 GSM | ~9-10 pt | Brochure covers, booklet covers |

| Cover Paper | 100 lb | 270 GSM | ~11-12 pt | Premium business cards, sturdy marketing materials |

| Cardstock | 110 lb | 300 GSM | ~12-14 pt | Thick business cards, high-end invitations |

| Cardstock | 120 lb | 325 GSM | ~14-15 pt | Wedding invitations, packaging boxes |

| Cardstock | 130 lb | 350 GSM | ~16 pt | Rigid packaging, luxury product boxes |

| Cardstock | 160 lb | 400 GSM | ~18-20 pt | Ultra-thick business cards, hardcover book covers |

| Newsprint | 28 lb | 42 GSM | ~2 pt | Newspapers, low-cost publications |

| Newsprint | 30 lb | 45 GSM | ~2.5 pt | Bulk print magazines, affordable books |

| Newsprint | 40 lb | 60 GSM | ~3 pt | Weekly magazines, cheap printing |

| Index Paper | 90 lb | 163 GSM | ~9-10 pt | Index cards, report covers |

| Index Paper | 110 lb | 200 GSM | ~11-12 pt | File folders, sturdy cards |

| Index Paper | 140 lb | 255 GSM | ~14 pt | Professional-grade index cards |

| Bristol Paper | 67 lb | 145 GSM | ~7-8 pt | Lightweight cardstock, invitations |

| Bristol Paper | 120 lb | 300 GSM | ~14 pt | Durable greeting cards, art projects |

| Bristol Paper | 160 lb | 400 GSM | ~18 pt | Thick cover stock, posters |

How to Use the Conversion Chart

Reading the Table

Basis Weight (lbs): This system, commonly used in the U.S., varies based on the paper type. For example, 50 lb text paper is much lighter than 50 lb cover paper because each type has a different standard sheet size for measurement.

GSM (g/m²): The most consistent global standard, GSM measures the actual weight of paper per square meter, making it the easiest system for direct comparison.

Thickness (pt): Point (pt) measures paper thickness in thousandths of an inch. This is especially important for packaging, cards, and specialty applications.

Considerations When Converting Between Units

Paper Type Matters: A direct comparison between bond, text, cover, and cardstock isn’t always accurate without considering sheet size differences.

Printing and Handling Requirements: Higher GSM and pt values indicate a thicker, more durable paper, which may require specialized printers.

Intended Use: Lightweight paper (60-100 GSM) is ideal for general printing, while heavier paper (175 GSM and above) is used for premium products like business cards and packaging.

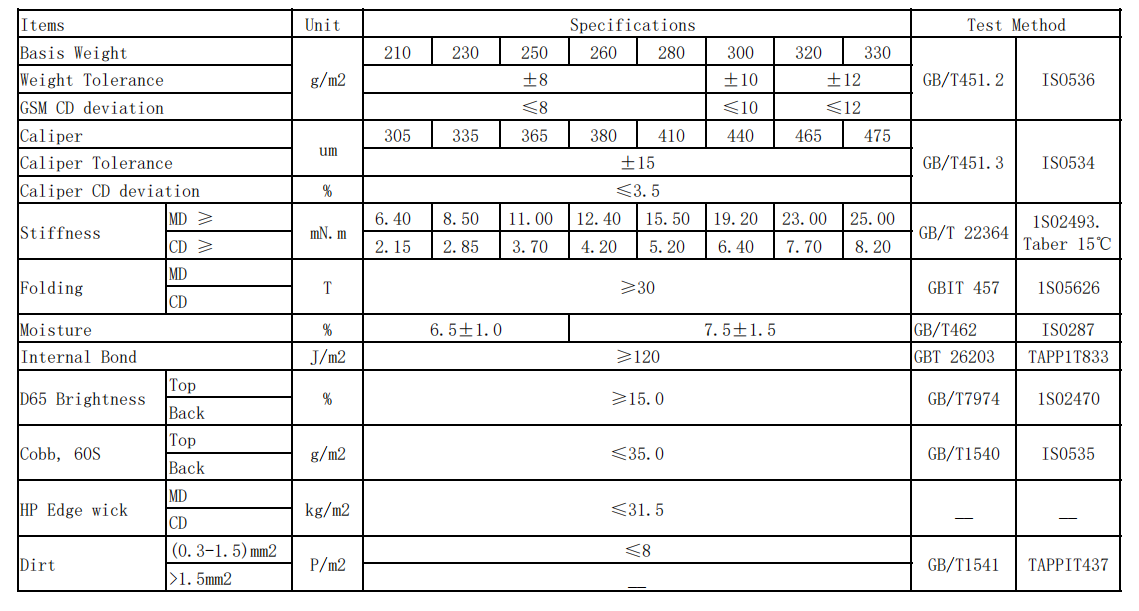

Factors Affecting Paper Weight and Thickness

When selecting paper for printing, packaging, or other applications, understanding the factors that influence paper weight and thickness is crucial. While weight (measured in GSM or lbs) provides a measure of mass, thickness (measured in points or mils) determines the physical feel and rigidity of the paper. The Paper Weight Conversion Chart helps standardize these values, but variations occur due to material composition and processing methods.

Paper Composition and Density

Influence of Fiber Density and Material on Actual Weight

The weight of paper is determined not only by its GSM or basis weight but also by the fiber composition and density:

High-density fibers (e.g., cotton or linen-based paper) add weight without significantly increasing thickness.

Low-density fibers (e.g., recycled pulp) result in bulkier yet lighter paper.

Paper with fillers (such as calcium carbonate in coated paper) increases weight while maintaining a smooth, thin structure.

Coated vs. Uncoated Paper

Coated Paper (glossy, matte, or satin finish) has an added layer that increases density and weight while keeping the paper relatively thin. This type is commonly used for magazines, brochures, and high-quality prints.

Uncoated Paper has a porous surface, making it thicker yet lighter for the same GSM. This type is widely used in books, standard office printing, and stationery.

Paper Thickness vs. Weight

Why Heavier Paper Isn’t Always Thicker

A common misconception is that higher GSM or basis weight directly correlates with thicker paper. However, various factors affect the actual thickness:

Pressing and calendaring processes compress fibers, making high-GSM paper thinner but denser.

Different paper types (text, bond, cover, cardstock) have unique weight-to-thickness ratios due to their intended uses.

For example:

A 100 lb text paper is much thinner than a 100 lb cover paper, even though both have the same basis weight.

Premium photo paper (200 GSM) may feel thinner than a 160 GSM cardstock due to its high-density coating.

Industry Standards for Specific Thickness-to-Weight Ratios

The printing and packaging industries follow general guidelines for weight-to-thickness conversion:

Copy paper (75-90 GSM): Lightweight and flexible, typically 3-5 pt thickness.

Magazine and brochure paper (100-150 GSM): Smooth yet thin, often 5-8 pt thickness.

Cardstock and cover paper (200-300 GSM): More rigid, typically 10-16 pt thickness.

Heavy-duty packaging board (350+ GSM): Thick and stiff, often exceeding 18 pt thickness.

190-350g Kraft PE Coated Paper Brown Cup Paper Cupstock Paper

Choosing the Right Paper Weight for Your Needs

Selecting the appropriate paper weight is essential for achieving the desired quality, durability, and functionality for different applications. Whether for printing, packaging, or crafting, understanding how paper weight impacts performance ensures optimal results. The Paper Weight Conversion Chart helps compare different measurement systems, but choosing the best weight also depends on the specific use case.

Printing and Publishing

Ideal Weights for Brochures, Business Cards, and Magazines

The weight of the paper directly affects the appearance, feel, and durability of printed materials:

Brochures and Flyers: Typically 100-150 GSM (60-100 lb text) to balance flexibility and professional presentation.

Business Cards: Require a heavier stock, usually 250-350 GSM (80-130 lb cover), for a sturdy and premium feel.

Magazines: Inside pages often range from 90-130 GSM (50-80 lb text), while covers require 200+ GSM (80-100 lb cover) for added durability.

Best Choices for Digital vs. Offset Printing

Digital Printing: Works well with thinner paper (75-200 GSM), as heavier stock can be difficult for some digital printers to handle.

Offset Printing: Compatible with a wider range of paper weights (60-400 GSM) and ideal for high-volume, professional-grade printing.

Packaging and Wrapping

Cardstock vs. Standard Cover Paper for Boxes and Labels

When choosing paper for packaging applications, thickness and rigidity are key factors:

Labels and Tags: Require paper in the 150-250 GSM range for flexibility and adhesive application.

Folding Cartons: Typically use 250-350 GSM (90-130 lb cover) cardstock for durability while maintaining foldability.

Rigid Packaging: High-end product boxes often use 400 GSM (150 lb cover) or thicker for a premium feel.

Factors to Consider for Shipping Durability

Tear and Bend Resistance: Heavier, coated papers withstand handling better.

Moisture Resistance: Laminated or coated stocks improve longevity.

Weight vs. Cost: Heavier materials increase shipping costs, so finding a balance between strength and efficiency is crucial.

Crafting and Specialty Uses

Recommended Weights for Invitations, Scrapbooking, and Handmade Cards

Different crafting projects require specific paper thicknesses:

Invitations: 200-350 GSM (80-130 lb cover) for an elegant and sturdy feel.

Scrapbooking: 120-200 GSM (70-100 lb text) for easy cutting and layering.

Handmade Cards: 250+ GSM (90+ lb cover) to provide a durable, professional touch.

Considerations for Embossing and Letterpress Printing

Heavier, uncoated paper (300+ GSM) works best for letterpress and embossing as it can withstand pressure without cracking.

Cotton-based paper absorbs ink well and enhances the depth of pressed designs.

Smooth vs. Textured Paper: Heavier textured paper (e.g., 350 GSM with a felt finish) adds a luxurious feel to specialty prints.

Conclusion

In conclusion, understanding paper weight conversions is essential for selecting the right paper for your specific needs. Whether you're working on printing, packaging, or crafting, using a conversion chart can help you make informed choices. Keep in mind that different systems like GSM, basis weight, and points all have their role in determining the best paper for your projects. Don't forget to refer to the chart when in doubt—it's a handy guide for achieving the best results.

References

[1] https://soloprinting.com/resources/paper-weight-conversions/

[2] https://smartpress.com/support/wp-content/uploads/2020/12/SPDC_PaperWeightConversionChart.pdf

[3] https://www.cardstock-warehouse.com/pages/cardstock-paper-basis-weight-chart

[4] https://www.carepac.com/blog/paper-thickness-conversion-chart/

[5] https://www.renoprintstore.com/tool-paper-weight-conversion-chart

[6] https://support.ricoh.com/bb_v1oi/pub_e/oi_view/0001073/0001073936/view/preparation/int/0214.htm

[7] https://envelopescanada.ca/pages/paper-weight-conversion-guide

[8] https://www.jampaper.com/paper-weight-chart

[9] https://www.binding101.com/media/downloads/PaperWeightComparisonChart.pdf

[10] https://pcforms.com/weight_chart.php