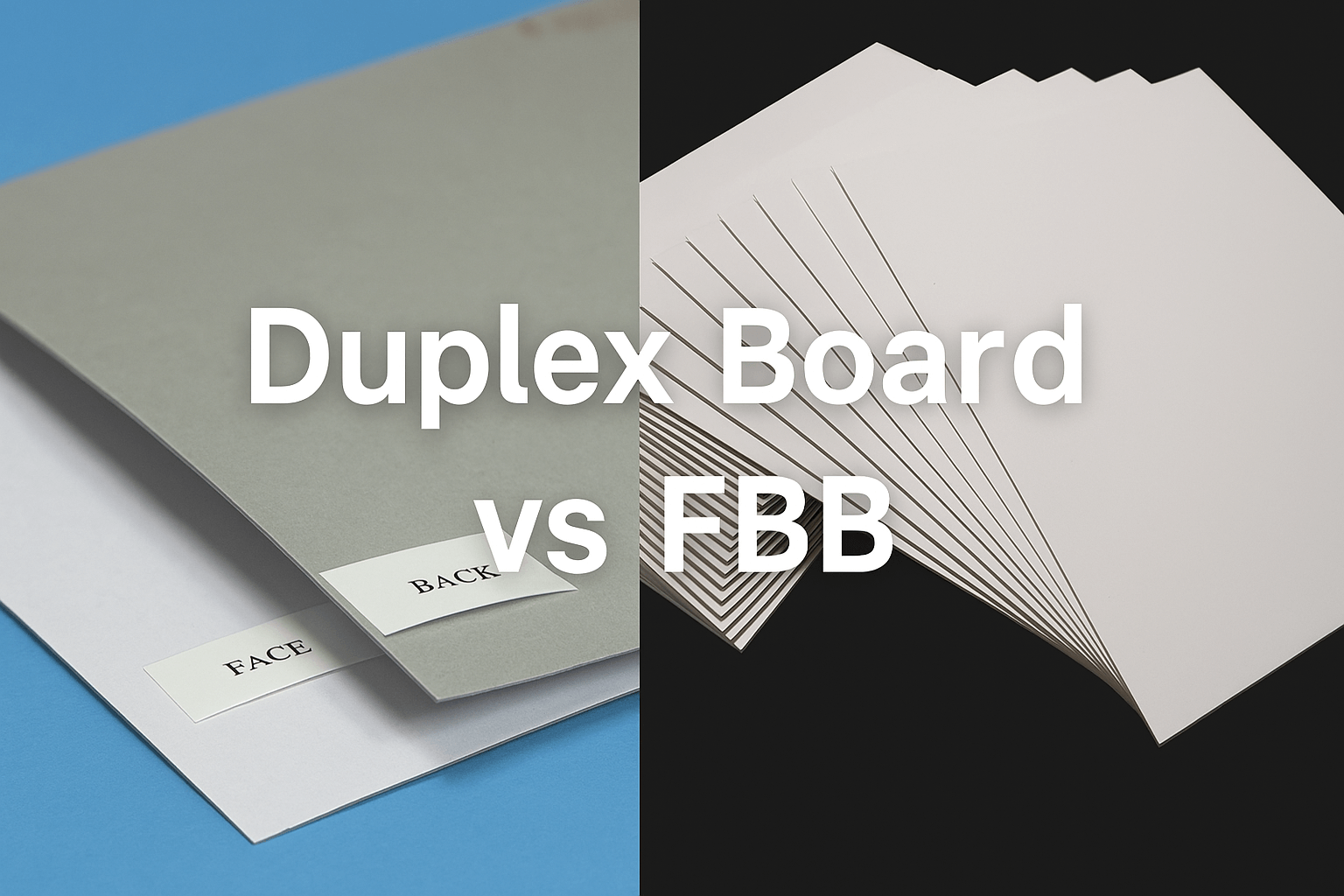

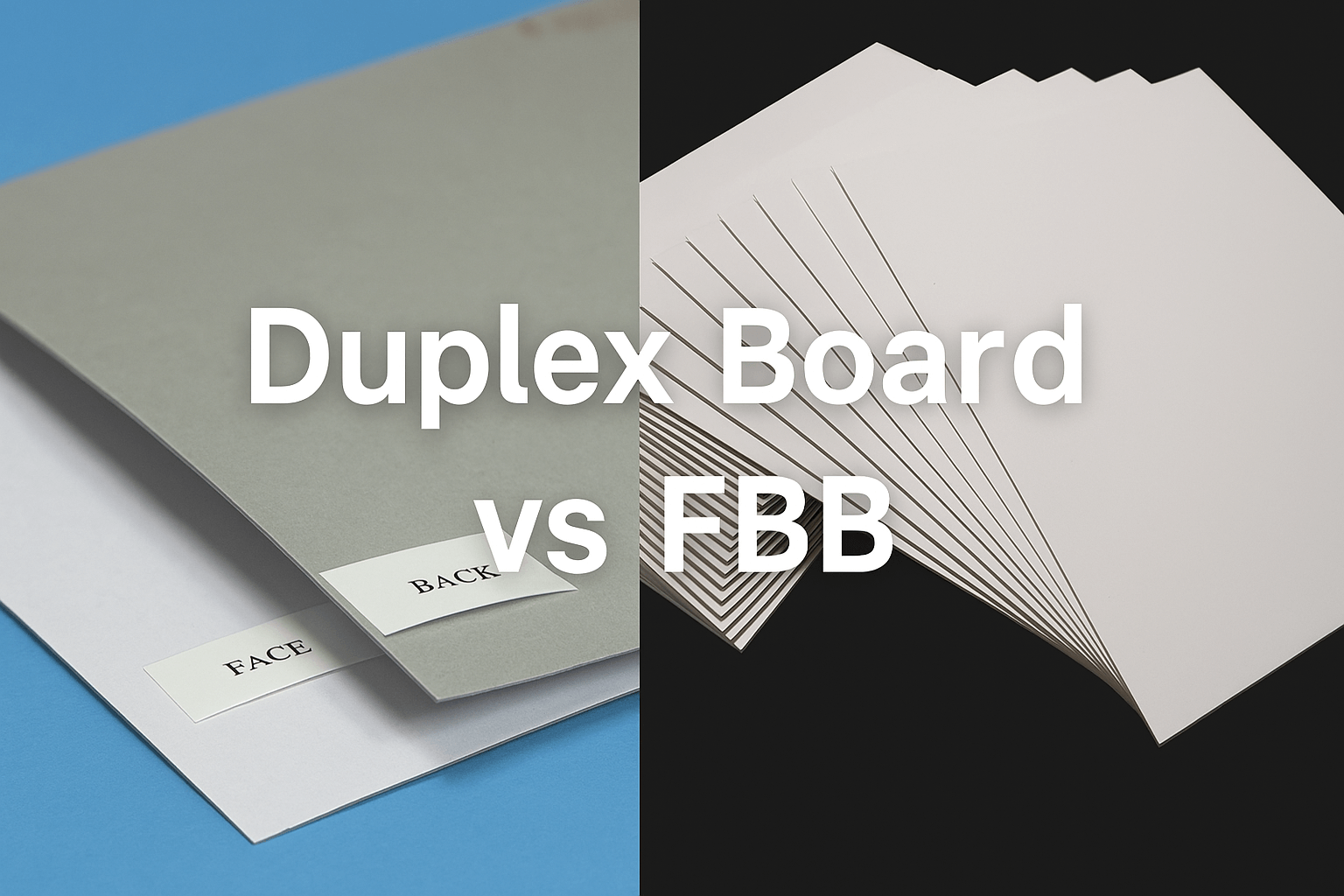

Choosing the right material for packaging can make or break a product’s success. Duplex Board vs FBB is a common comparison in the packaging world, especially for businesses seeking strength, printability, and versatility. But how do you know which one is best for your needs?

In this post, you'll explore the differences between Duplex Board and Folding Box Board (FBB), from structure and surface finish to print quality and use cases. Whether you're in food, cosmetics, or retail, this guide will help you make smarter packaging decisions.

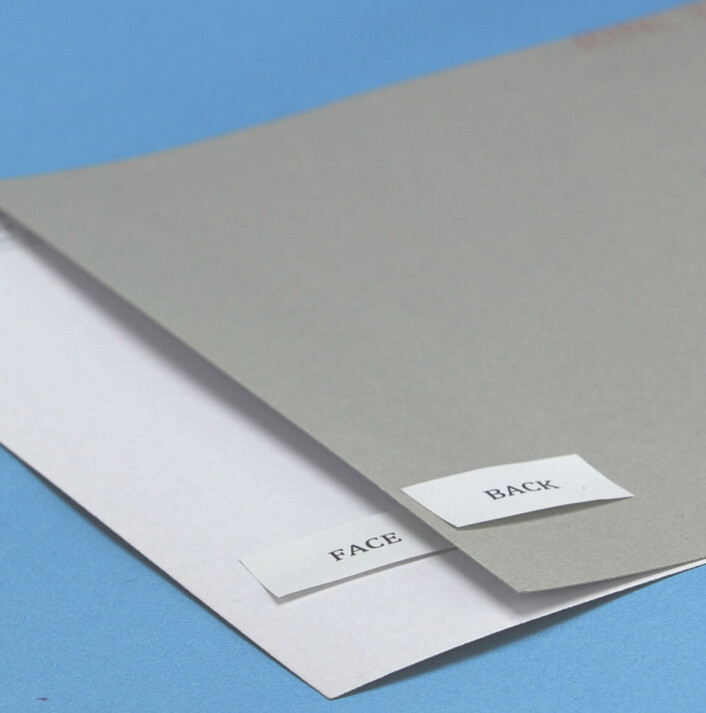

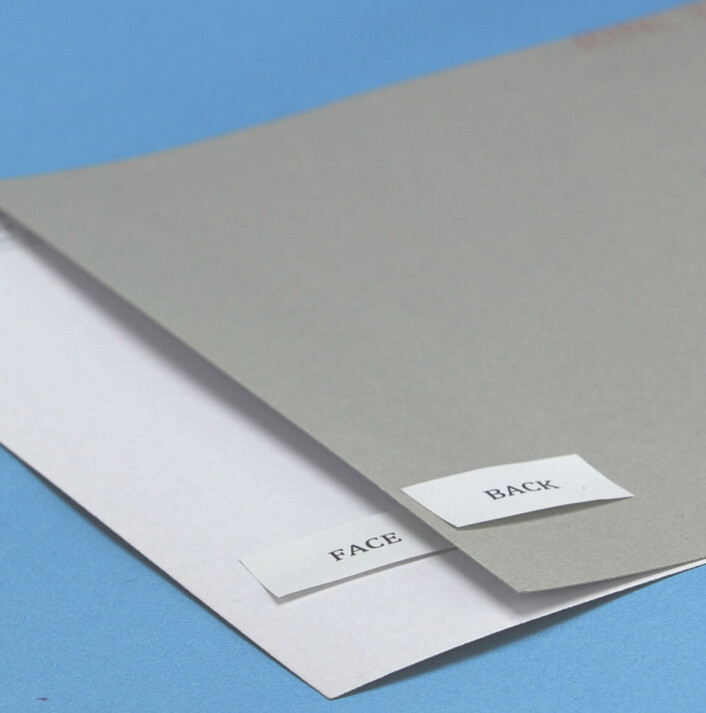

What is Duplex Board?

Duplex board is a versatile packaging material made from two layers of paper. The top layer is typically white or bleached, designed for visual appeal and printability. The bottom layer can vary—grey, kraft, or white—depending on its intended use. It comes in both coated and uncoated versions, which affects surface smoothness and ink absorption.

Key Properties of Duplex Board

Duplex board usually falls within a thickness of 200 to 450 GSM. It offers reliable strength and rigidity, making it ideal for packaging that needs to protect its contents while maintaining a clean appearance. Coated variants allow better print quality, while uncoated ones focus more on durability and cost-effectiveness.

Main Properties:

Available in medium to heavy GSM range (200–450)

One side smooth for printing, other side functional

Strong enough for shipping and display boxes

Often made with recycled pulp for economy

Common Types of Duplex Board

There are several types of duplex board, each with specific uses depending on its coating and back color.

| Type | Description |

| Coated Duplex Board | Smooth top surface; ideal for high-quality print and branding |

| Uncoated Duplex Board | Rougher finish; more affordable for bulk or industrial use |

| Grey Back | Economical option where only one side is visible |

| White Back | Both sides visible; used for premium retail or consumer goods |

| Kraft Duplex Board | Rustic brown backside; suits eco-styled designs and natural product packaging |

| Wax-Coated Board | Offers moisture resistance; useful in frozen food or perishables packaging |

Applications of Duplex Board

Duplex board is widely used across industries. Its balance of strength, flexibility, and affordability makes it a go-to for many packaging needs.

Retail Product Packaging: Perfume boxes, mobile accessories, toys

Cosmetics & Electronics: Rigid boxes for compact products

Stationery: Book covers, folders, index tabs

Display Packaging: Stands, header cards, product showcases

Folding Cartons: Lightweight shipping boxes and inner packaging

What is FBB (Folding Box Board)?

FBB stands for Folding Box Board. It’s a paperboard material made from multiple layers—specifically, a middle layer of mechanical pulp placed between two outer layers of bleached chemical pulp. This structure gives it both a lightweight body and high stiffness, making it ideal for folding cartons. Its surface is bright and smooth, which helps with clear printing and visual appeal. Compared to Solid Bleached Sulfate (SBS), FBB is slightly less dense but often preferred when packaging requires rigidity over thickness.

Layer Composition Table:

| Layer Position | Material Used | Function |

| Outer Layer | Bleached chemical pulp | Smoothness, printable surface |

| Middle Layer | Mechanical pulp | Bulk, stiffness |

| Bottom Layer | Bleached or coated pulp | Additional strength and print option |

Key Properties of Folding Box Board

FBB is known for its ability to stay firm while being lightweight. That’s why it’s a popular choice for packaging where both performance and appearance matter. Its fully bleached surface makes colors appear brighter, sharper, and more consistent. This is especially helpful for packaging that requires logos, images, or fine text. Many versions of FBB also include coatings or treatments to make them resistant to moisture, helping protect the items inside—especially food or pharmaceuticals.

Highlights:

Feels light but holds shape under pressure

Smooth, white surface enhances printed graphics

Performs well under folding or creasing

Some types provide moisture protection

Types of FBB and Related Grades

There are different forms of FBB designed for specific use cases. Coated FBB—whether coated on one side (C1S) or both (C2S)—improves ink coverage and gloss. PE-coated FBB includes a polyethylene layer that prevents moisture penetration, making it perfect for frozen foods or items stored in humid conditions. When compared to SBS, FBB offers better stiffness at the same GSM but may not be as smooth or pure in color tone.

Applications of FBB

Folding Box Board has a wide range of packaging uses across industries. It’s commonly used in food packaging like cereal, chocolate, and frozen meals. Its clean surface and structure also make it ideal for pharmaceutical boxes, where clear labeling is essential. In cosmetics, brands often choose FBB for items like creams and makeup sets to reflect a premium look. It’s also used for luxury product boxes—think electronics, fragrances, and fine accessories—thanks to its balance of visual impact and reliable structure.

Duplex Board vs FBB: In-Depth Comparison

1. Material Composition

When comparing Duplex Board and FBB, the first major difference lies in their material composition. Duplex board is made primarily from recycled paper fibers, which makes it a more affordable and environmentally friendly option. However, the use of recycled fibers often results in a slightly less refined product. FBB, on the other hand, is composed of 100% virgin pulp, ensuring superior strength and a smoother, more consistent surface. This makes FBB ideal for high-end packaging where quality cannot be compromised.

| Material | Duplex Board | FBB |

| Fiber Source | Recycled Paper Fibers | Virgin Pulp |

| Quality | Moderate | High |

| Cost | Lower | Higher |

2. Surface Finish and Printability

Coated vs Bleached Smoothness

Surface finish plays a critical role in how the material holds up during printing. Duplex board typically has a bleached smooth finish, which, while adequate, may show some imperfections in print. It is more prone to ink spread, which can result in less sharp graphics.

FBB, with its coated surface, is much smoother and more even, providing a better foundation for printing. This is why it’s often used for products that demand a pristine visual appeal, such as luxury packaging. The smoother surface also minimizes dot gain, a common issue in duplex board, where the ink spreads beyond its intended area, leading to a loss of detail in printed designs.

Print Clarity and Ink Absorption

Because of its higher quality surface, FBB is superior when it comes to print clarity and ink absorption. It allows for vibrant, detailed prints without the risk of bleeding or smudging. On the other hand, Duplex board might not absorb ink as evenly, which can lead to some inconsistency in color, particularly with more intricate designs.

3. Strength and Durability

Load-Bearing Capacity

When it comes to strength and durability, FBB is the clear winner. Thanks to its virgin pulp composition, FBB can handle greater weight, making it ideal for packaging heavier products without compromising structural integrity. Duplex board, while sturdy, may not handle the same amount of pressure and tends to show creases or bends when exposed to heavy loads.

Resistance to Folding and Bending

FBB excels in its resistance to folding and bending, retaining its shape even during extensive handling. This is why it’s commonly used for rigid boxes, where the packaging must maintain a pristine appearance. Duplex board, while still strong, is more prone to bending and creasing, which can be an issue when handling bulkier products or those requiring extra durability.

| Attribute | Duplex Board | FBB |

| Load-Bearing Capacity | Moderate | High |

| Bend Resistance | Moderate | High |

| Durability | Moderate | High |

4. Cost and Availability

One of the primary advantages of Duplex board is its cost-effectiveness. It’s an excellent choice for bulk applications where the price needs to be kept low, but the material still needs to provide enough strength and printability. This makes it a popular choice in industries like food packaging or e-commerce, where packaging needs to be functional without breaking the budget.

On the flip side, FBB comes at a higher price due to its use of virgin pulp and superior finish. While it is more expensive, the price is justified by its premium qualities, such as better printability and increased durability. FBB is typically chosen for high-end products, like luxury goods and cosmetics packaging, where the appearance and performance of the packaging are critical.

Cost Comparison

Duplex Board: Affordable, great for bulk applications.

FBB: Higher price but offers premium quality and durability.

5. Packaging Performance and Use Case Fit

Shelf Appeal and Consumer Perception

FBB shines when it comes to shelf appeal. Its smooth, high-quality surface allows for vibrant prints, making it the go-to choice for luxury products. Packaging made from FBB often carries a premium feel, which can influence consumer perception and boost the product’s marketability.

Duplex board, on the other hand, is more functional than flashy. While it provides the durability needed for many everyday applications, such as food packaging, it may not offer the same level of visual appeal as FBB. However, for many products, this is a fair trade-off, as Duplex board is significantly more affordable.

Best Use Case for Rigid Boxes vs Folding Cartons

When deciding between rigid boxes and folding cartons, FBB is the better choice for rigid boxes, especially for products that demand both visual appeal and protection. Duplex board is more suited for folding cartons, which are commonly used for lighter, everyday products.

6. Industry-Specific Preferences

Which Industries Prefer Duplex Board?

Industries that prioritize cost-efficiency often choose Duplex board. It is a preferred option for packaging in the food industry, e-commerce, and consumer goods. These sectors require durable packaging that won’t break the bank, and duplex board fits that need perfectly.

Which Industries Rely on FBB?

For industries that prioritize luxury and durability, such as cosmetics, pharmaceuticals, and high-end retail products, FBB is the go-to material. The superior finish, durability, and print quality make FBB ideal for packaging that needs to make an impression on consumers.

| Industry | Preferred Material |

| Duplex Board | Food, E-commerce, Consumer Goods |

| FBB | Cosmetics, Pharmaceuticals, Luxury Goods |

How to Choose Between Duplex Board and FBB

Key Questions to Ask

What Product Are You Packaging?

If you’re packing heavier or luxury items, FBB is a better choice. For lighter products, Duplex board is cost-effective and sufficient.

What Level of Print Quality Is Required?

Need high-quality, sharp prints? Go for FBB. Its smooth surface ensures better clarity, while Duplex board is more suited for simple designs.

What’s Your Packaging Budget?

For a budget-friendly option, Duplex board is the way to go. It provides good strength and functionality at a lower cost, while FBB can be pricier due to its premium material.

Is Box Stiffness Important?

For stronger, more rigid packaging, FBB excels. It resists bending and holds up well under pressure. Duplex board is more flexible but may bend easier.

Use Case Scenarios

For budget packaging with decent print: Duplex board

For high-end or luxury items: FBB

For pharmaceutical or food-grade packaging: FBB

For general retail products: Depends on weight and aesthetic preference—Duplex board for lighter items, FBB for premium products

High Quality Sunrise Folding Box Board

Summary Table: Duplex Board vs FBB Comparison

Here’s a quick comparison between Duplex Board and FBB, making it easier to decide which material fits your packaging needs.

| Feature | Duplex Board | FBB |

| Material Composition | Recycled fibers, cost-effective | Virgin pulp, premium quality |

| Surface Finish | Bleached, may have imperfections | Smooth, coated finish |

| Print Quality | Decent, may show ink spread | High-quality, sharp prints |

| Strength & Durability | Moderate, prone to bending | High, resistant to pressure |

| Cost | Lower, budget-friendly | Higher, premium material |

| Use Case | Everyday, light packaging | High-end, luxury products |

Key Takeaways:

Duplex board is great for cost-sensitive projects that don’t require top-tier print quality.

FBB shines when durability and high print quality are essential, especially for premium products.

Conclusion

Choosing between Duplex Board and FBB depends on your packaging needs. Duplex board is affordable and functional for lightweight, budget-conscious packaging. FBB, on the other hand, provides superior strength, print quality, and a premium finish, making it ideal for high-end products. Always consider performance, not just price, when making your choice.

To ensure your packaging fits your product's requirements, evaluate the material’s strength, printability, and cost-effectiveness. The right choice can improve your product’s appeal and durability, enhancing the overall customer experience.

FAQs

1. Is Duplex Board suitable for food packaging?

Yes, Duplex board is commonly used for food packaging due to its affordability and durability. However, it may require additional coatings for moisture protection.

2. Which board offers better print quality?

FBB offers superior print quality thanks to its smooth, coated surface, making it ideal for detailed and vibrant prints.

3. What’s the most cost-effective option for startups or small businesses?

Duplex board is the more cost-effective choice, providing solid packaging solutions at a lower price, perfect for startups or small businesses.

4. Can both Duplex Board and FBB be used in pharmaceutical packaging?

Yes, both materials can be used, but FBB is generally preferred for pharmaceutical packaging due to its higher strength and premium finish.